24

Section 5: Maintenance & Lubrication

RCF2760 and RCF2772 Rotary Cutters 326-460M

12/15/15

Table of Contents

4. Inspect clutch and ensure that the scribed markings

made on the clutch plates have changed position.

Slippage has not occurred if any two marks on the

friction disc and plate are still aligned. A clutch that

has not slipped must be disassembled to separate

the friction disc plates. See “Clutch Assembly and

Disassembly” on page 24.

5. Tighten each of the 8 spring retainer nuts on the

clutch housing exactly 2 revolutions to restore the

clutch to the original setting pressure.

6. The clutch should be checked during the first hour of

cutting and periodically each week. An additional set

of scribe marks can be added to check for slippage.

See Figure 5-4 to adjust spring length.

Clutch Assembly and Disassembly

Disassembly

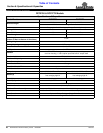

Refer to Figure 5-3:

See IMPORTANT NOTE above before disassembling

clutch. After measuring and recording each spring length,

remove spring retainer nuts (#1), springs (#2), and bolts

(#3). Each friction disc (#4) must then be separated from

the metal surface adjacent to it. Refer to the Parts Manual

for a detailed parts breakdown.

Inspection

Inspect all parts for excessive wear and condition. Clean

all parts that do not require replacement.The original

friction disc thickness is 1/8" (3.2mm) and should be

replaced if thickness falls below 3/64" (1.1mm). If

clutches have been slipped to the point of “smoking”, the

friction discs may be damaged and should be replaced.

Heat build-up may also affect the yoke joints.

Assembly

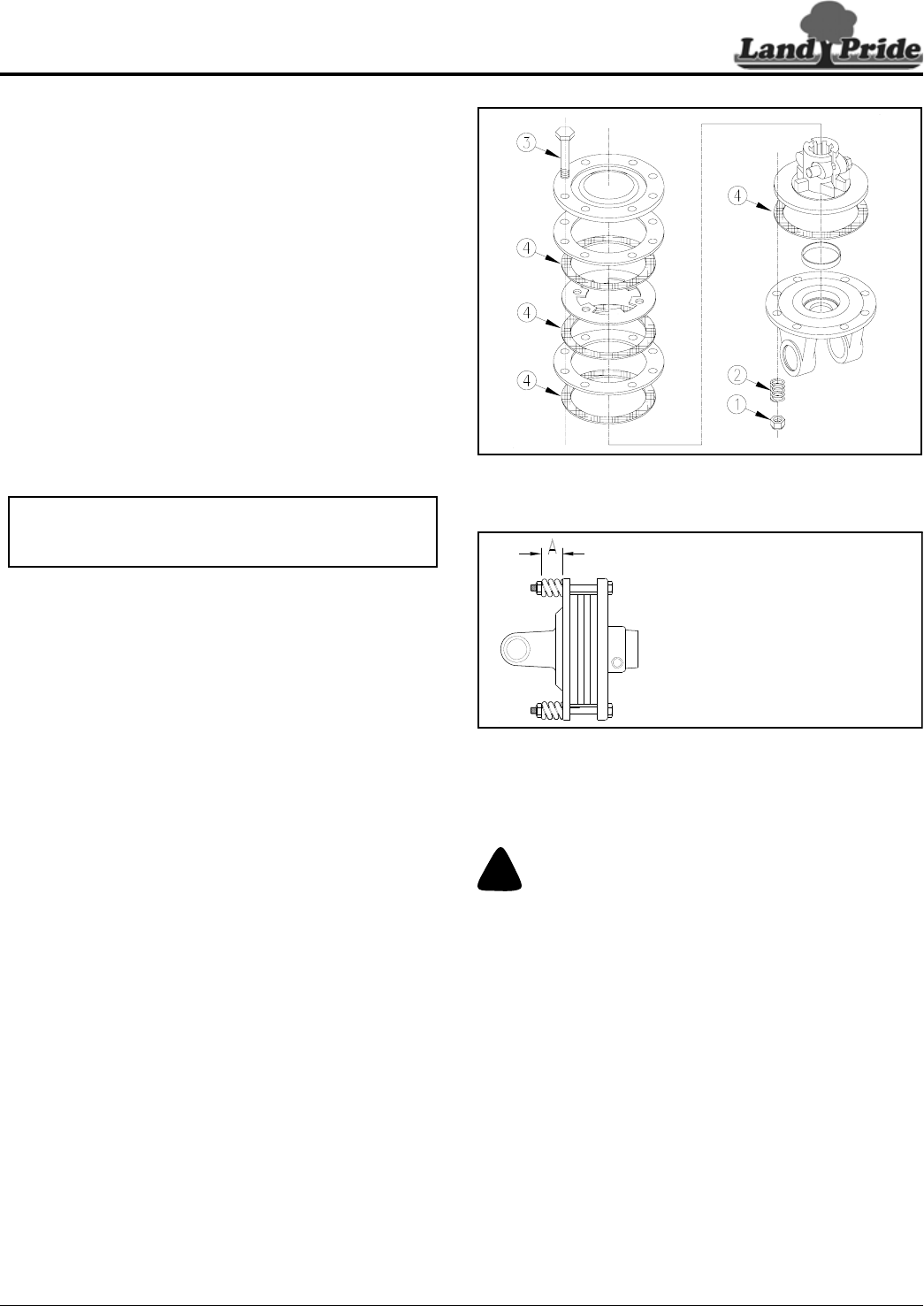

Refer to Figure 5-4:

Reassemble each friction disc (#4) next to the metal plate

it was separated from. Install bolts (#3) through the end

plates and intermediate plates as shown. Place springs

(#2) over bolts (#3) and secure with nuts (#1).

Progressively tighten each spring retainer bolt until

correct spring height “A” dimension is obtained.

IMPORTANT: Refer to Figure 5-4. Be Sure to

measure and record length (“A”) of each clutch

spring before disassembling clutch.

Clutch Disassembly

Figure 5-3

Clutch Adjustment

Figure 5-4

Skid Shoe Maintenance

Refer to Figure 5-5 on page 25:

!

WARNING

Excessive wear on skid shoes can damage side panels, cause

inadequate operation of cutter, and create a safety hazard.

Always replace skid shoes at the first sign of wearing thin.

There are skid shoes mounted on the cutter sides. Check

both skid shoes for wear and replace if necessary. Order

only genuine Land Pride parts from your local Land Pride

dealer.

1. Remove 3/8" hex whiz nuts (#3), 3/8" plow bolts (#2),

and skid shoe (#1) as shown.

2. Plow bolts should be checked for wear and replaced

if necessary.

3. Attach new skid shoe (#1) to cutter with existing

3/8" plow bolts (#2) and secure with 3/8" hex whiz

nuts. Tighten to the correct torque.

4. Repeat on opposite side.

23554

24600

A = Measured length of each spring

before disassembling slip clutch.

Use 1.319" for “A” dimension if

measurements were not taken befor

disassembling slip clutch.