28

Section 5: Maintenance and Lubrication

AFM4522 All Flex Grooming Mower 315-360M

11/14/08

Land Pride

Table of Contents

Driveline Protection

Mower drive components are protected from shock loads

by a two plate friction clutch. The clutch should slip

during operation to protect the mower from excessive

loads.

Friction clutches should be “run-in” prior to initial

operation and after long periods of inactivity. To prevent

driveline and gearbox damage, repeat “Run-In”

instructions at the beginning of each season and when

moisture and/or condensation seizes the inner friction

plates.

Clutch Run-In

Refer to Figure 5-9 (View - A):

1. Using a pencil or other marker, scribe a line across the

exposed edges of the clutch plates and friction disks.

2. Tighten all 4 nuts uniformly until the spring load is low

enough that the clutch slips freely with the PTO

engaged.

3. Start the tractor and engage driveline drive for 2-3

seconds to permit slippage of the clutch surfaces.

Disengage the driveline, then re-engage a second

time for 2-3 seconds. Disengage driveline, shut off

tractor and remove key. Wait for all components to

stop before dismounting from tractor.

4. Inspect the clutch and ensure that the scribed

markings made on the clutch plates have changed

position. Slippage has not occurred if any two marks

on the friction disk and plate are still aligned. A clutch

that has not slipped must be disassembled to

separate the friction disk plates. See Clutch

Disassembly & Assembly on page 28.

Refer to Figure 5-9 (View - B):

5. Turn all 4 nuts fully back if no two marks on the

friction disk and plate are still aligned. Clutch is ready

for use.

6. The clutch should be checked during the first hour of

cutting and periodically each week. An additional set

of scribe marks can be added to check for slippage.

Clutch Run-In

Figure 5-9

Clutch Disassembly & Assembly

If “Clutch Run-In” procedure indicated that one or more of

the friction disks did not slip, then the clutch must be

disassembled to separate the friction disks.

22171

NOTE: Before proceeding, secure the clutch firmly

in a vise or other clamping device to prevent injury.

10435

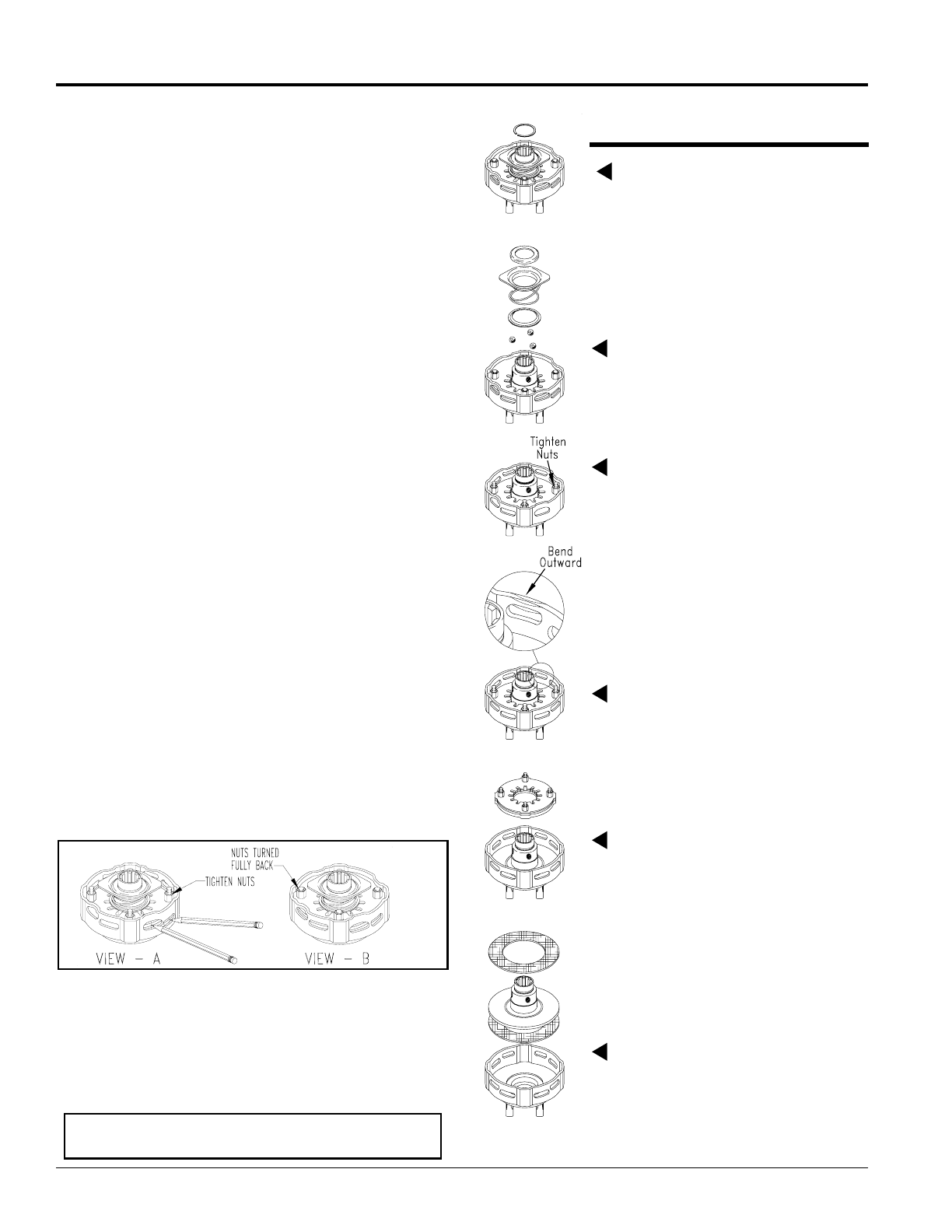

Step 2

Remove backup ring, lock collar,

compression spring, bottom backup

ring, and balls.

Step 3

Tighten the four hex nuts uniformly

until the clutch pack and hub are

loose.

Step 4

Bend all four retaining lugs out on

edge of clutch housing.

Step 5

Remove thrust plate with Belleville

Springs and lug rings to access

friction discs and hubfor inspection or

service.

Disassembly

Step 1

Remove snap ring.

Step 6

Inspect friction discs and hub.