11

Section 1: Assembly and Setup

11/14/08

AFM4522 All Flex Grooming Mower 315-360M

Land Pride

Table of Contents

Section 1: Assembly and Setup

Tractor Requirements

Tractor horsepower should be within the range noted

below. Tractors outside the horsepower range must not

be used.

Horsepower Rating . . . . . . . . . . . . . . . . . . 65-100 HP

Rear PTO Shaft Type. . . . . . . . . . . . . .1 3/8”-6 Spline

Rear PTO Speed . . . . . . . . . . . . . . . . . . . . 540 RPM

Hitch Type . . . . . . . . . . . . . . . . . . . . . . . . . . Draw Bar

Hydraulic Outlets . . . . . . . . . . . . . .One Duplex Outlet

Tractor Weight . . . . . . . . . .See Important Note Below

Hardware Torque Information

When tightening hardware, refer to “Torque Values

Chart” on page 39 to determine standard torque values.

Refer to "Additional Torque Values" at the bottom of the

chart for exceptions to the standard torque values.

Dealer Preparations

This mower has been partially assembled at the factory.

some additional preparations will be necessary to finish

assembling the mower and to attach it to the customer’s

tractor. Ensure that the intended tractor conforms to the

requirements stated under the heading “Tractor

Requirements”.

IMPORTANT: Ballast may need to be added to your

tractor to maintain steering control. Refer to your

tractor’s operator manual to determine if additional

ballast is needed. This mower has a positive

transport tongue weight of approximately 540 lbs. on

the AFM4214 and 580 lbs. on the AFM4216.

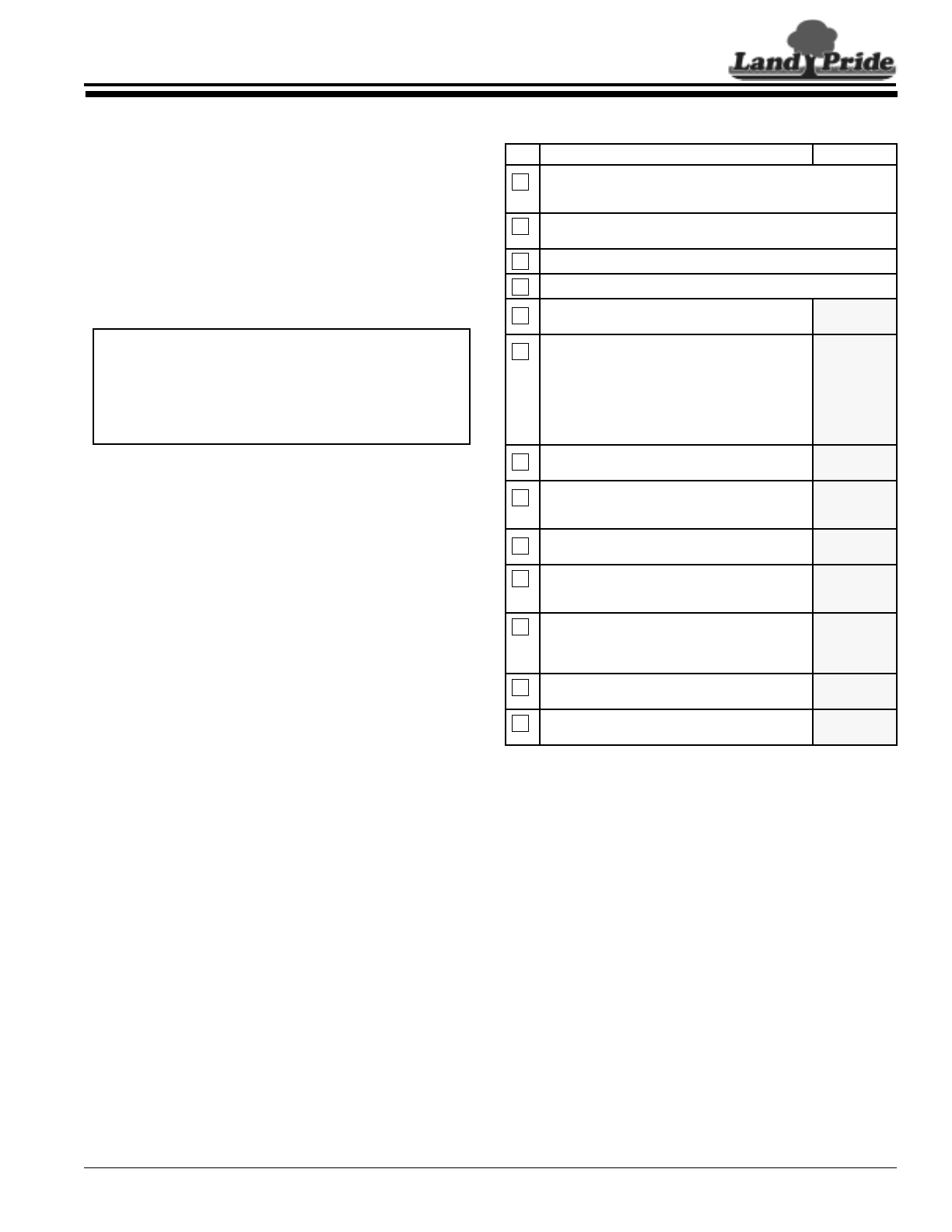

Pre-Assembly Checklist

Check Reference

Make sure miscellaneous assembly tools are on hand: Hammer,

tape measure, hacksaw,assortment of wrenches & sockets, 3/8"

drill, drill bits and spirit level.

Have a forklift or hoist with properly sized chains and safety

stands on hand capable of lifting 2500 lbs.

Have a minimum of two people available during assembly.

Check to see if auxiliary tractor weights are needed.

Make sure all major components and loose parts

are shipped with the machine.

Operator’s

Manual

Double check to make sure all fasteners & pins

are installed in the correct location. Refer to the

Parts Manual if unsure.

NOTE: All assembled hardware from the factory

has been installed in the correct location.

Remember location of a part or fastener if

removed during assembly. Keep parts separated.

Operator’s

Manual

Make sure working parts move freely, bolts are

tight & cotter pins are spread.

Operator’s

Manual

80-90 EP Gear Lube must be added to the

gearbox & motor as indicated in the

“Maintenance & Lubrication”.

Section 5

Page 30

Make sure all drive chains are properly tension

and aligned.

Operator’s

Manual

Make sure all safety labels are correctly located

and legible. Replace if damaged.

Important

Safety

Information

Make sure all red and amber reflectors are

correctly located and visible when machine is in

transport position.

Important

Safety

Information

Page 1

Make sure all tires are inflated to the specified

psi air pressure.

Section 8

Page 39

Make sure all wheel bolts and axle nuts are

tightened to the specified torque.

Section 8

Page 39