Dealer Service 23

WPMAN0142 (Rev. 9/1/2004)

GEARBOX MAINTENANCE

Read all of this section before starting any repair. Many

steps are dependent on each other.

Check gearbox for leakage and shaft side and end

play. If excessive shaft play is found, disassemble

gearbox and inspect bearings and shafts.

Leakage can occur at top cover and at shaft seals.

Leakage problems should be corrected immediately to

prevent damage to drive belt from gearbox oil.

Always clean any spilled lubricant with a cloth moist-

ened with a non-flammable, non-toxic degreasing

agent or commercial detergent and water. Be sure to

clean pulley grooves.

The sealants recommended for gearbox repair are Per-

matex

®

Aviation 3D Form-A-Gasket or Loctite

®

1

515

Gasket Eliminator.

Leakage Repair

To repair top cover leakage, clean top cover and hous-

ing sides, then remove cover. Remove old sealant from

cover and housing.

Apply sealant to top cover and replace. Retorque hous-

ing bolts.

Horizontal seal leakage should be repaired by replac-

ing the seal. The gearbox should be removed from the

mower to accomplish this. Remove old seal with care

to prevent damage to seal bore and shaft. Sealant

should be applied to the seal bore before installing the

new seal. The new seal should be seated squarely in

the bore against snap ring. Press seal into place with a

piece of pipe or tubing that sets against the outside

edge of the seal. Tubing with an outside diameter that

is too small will bow seal cage and ruin the seal.

Removing Gearbox from Mower

Remove belt and driveline shields.

Remove rear driveline shield bearings and remove

shield. Remove snap ring from gearbox shaft. Remove

shear bolt from end yoke and remove driveline.

Remove drive belt from drive sheave.

Remove gear stand from mower.

Remove drive sheave from mower by removing bolts

from split taper bushing and turning them into threaded

holes on bushing flange. Tighten evenly, forcing the

bushing and drive sheave apart.

Remove gearbox from gear stand.

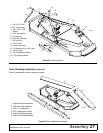

Gearbox Disassembly

(Figure 22)

Remove gearbox from cutter as follows: Disconnect

and remove the rear driveline from the gearbox.

Remove vent plug (27) and siphon gear lube from

housing through this opening. Remove cotter pin,

washer, and nut from vertical shaft and remove cross-

bar. Remove the four bolts that hold the gearbox on the

cutter.

Remove 3/8" plug from side of gearbox and pour out

gear oil.

Remove oil cap (23) (to be replaced), snap ring (12),

and shim (15) from input shaft (3).

Support gearbox in hand press and push on the input

shaft (3) to remove bearing (9) and spacer (14).

Remove top cover (25) from housing and gear (1) from

inside housing.

Remove oil seal (22) from front of housing (to be

replaced). Remove snap ring (12) and shim (15) from

front of housing.

Support housing in vise in a horizontal position. The

castle nut (17), cotter pin (28), washer (18), and hub

(24) are already removed with the stump jumper/cross-

bar. Remove the snap ring (10), washer (19), and seal

(21).

Remove cotter pin (11), castle nut (16), and washer

(20) from output shaft (4). Remove output shaft by

using a punch and hammer; tap on the top to drive

down.

Remove gear (5) and shim (15) from inside housing.

Remove bearing (7) by using a punch and hammer

from the top, outside the housing. Support housing

upside down (top cover surface) and remove bearing

(6) by using a punch and hammer from the bottom side

of the housing.

Inspect gears for broken teeth and wear. Some wear is

normal and will show on loaded side. Forged gear sur-

faces are rough when new. Check that wear pattern is

smooth.

Inspect vertical and horizontal shafts for grooves,

nicks, or bumps in the areas where the seals seat.

Resurface any damage with emery cloth. Inspect hous-

ing and caps for cracks or other damage.

1. Loctite is a registered trademark of the Henkel Loctite

Corporation.