41

Maintenance

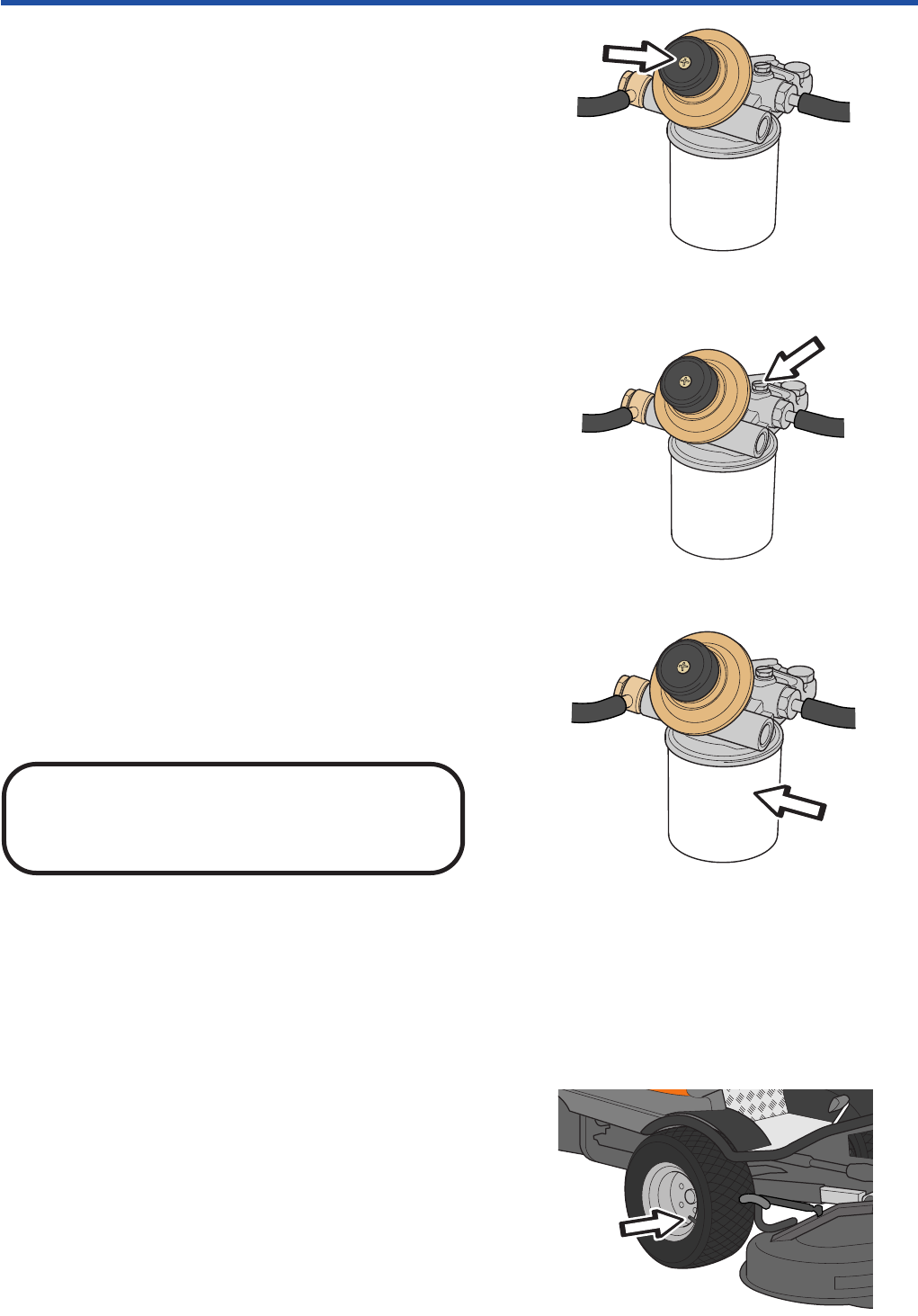

Bleeding the fuel system

If you have run out of fuel, the fuel system must be

bled. Facilitatebleeding by pumping using a hand

pump. Remove the fuel tank filler cap and check the

return fuel to the tank. When bubble free fuel flows to

the tank, the engine can be started.

Carry out full bleeding as follows:

1. Slacken off the bleed screw on the fuel filter holder

at least 1/2 a turn.

2. Pump using the hand pump until clean fuel,

without air bubbles, exits the drain hole. Tighten

the screw moderately.

3. Slacken off the bleed screw on the injection pump

at least 1/2 a turn. Pump using the hand pump until

clean fuel, without air bubbles, exits the drain hole.

Tighten the screw moderately.

4. Rotate the engine with the starter motor for a

maximum of 15 seconds. Wait 30 seconds before

the next start attempt.

Servicing the fuel filter

The fuel filter must be replaced regularly, for intervals

see Maintenance schedule, page 35, or if the feed

pressure, has dropped below the permitted value due

to a blocked filter. Low feed pressure can also be due

to poor fuel hygiene, e.g. defective excess flow valve.

The fuel filter should be replaced by a qualified

technician, there is a risk of damaging the injection

pump if carried out incorrectly. Contact your

Husqvarna workshop.

Used fuel filters areare environmentally hazardous

waste.

Checking the Tyre Pressures

The tyre pressure must be 100 kPa / 1.0 bar / 14.5 PSI

for the front and rear wheels.

The air pressure in cutting unit's pivot wheels should

be 150 kPa / 1.5 bar / 21.8 PSI.

IMPORTANT INFORMATION:

Hand pump

Bleed screw on fuel filter holder

Fuel filter

All action taken in the fuel system requires utmost

cleanliness to prevent damaging the injection pump.

Use a qualified technician. Damage caused by poor

hygiene is not covered by the warranty.

Tyre pressures