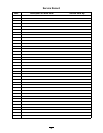

Troubleshooting

Problem Possible Cause Corrective Action

1. Engine load is excessive 1. Reduce the ground speed.

2. Oil level in the crankcase is low.

2. Add oil to the crankcase.

Engine overheats

3. Cooling ns and air passages for the

engine are plugged.

3. Remove the obstructions from the cooling

ns and air passages.

1. Tracking needs adjustment 1. Adjust the tracking.

2. Tire pressure in drive tires not correct. 2. Adjust tire pressure in the drive tires.

Mower pulls left or right (with levers fully

forward)

3. Reverse indicator and motion control

linkage need adjustment.

3. Adjust the reverse indicator and the

motion control linkage.

1. Bypass valve is not closed tight. 1. Tighten the bypass valve.

2. Drive or pump belt is worn, loose or

broken.

2. Change the belt.

3. Drive or pump belt is off a pulley. 3. Change the belt.

4. Broken or missing idler spring.

4. Replace the spring.

Machine does not drive

5. Hydraulic uid level is low or too hot. 5. Add hydraulic uid to reservoir or let it

cool down.

1. Blade(s) not sharp. 1. Sharpen the blade(s).

2. Cutting blade(s) is/are bent.

2. Install new cutting blade(s).

3. Mower deck is not level. 3. Level mower deck from side-to-side and

front-to-rear.

4. Underside of mower is dirty. 4. Clean the underside of the mower.

5. Tire pressure in drive tires not correct. 5. Adjust tire pressure in the drive tires.

6. Blade spindle bent. 6. Contact an Authorized Service Dealer.

Uneven cutting height.

7. Tips of adjacent blades are at an uneven

cutting height. Blades tips should be even

within 3/16 inch which is approximately

one blade thickness.

7. Replace blades, spindles and (or) check

for damage to mower deck.

1. Cutting blade(s)is/are bent orunbalanced.

1. Install new cutting blade(s).

2. Blade mounting bolt is loose. 2. Tighten the blade mounting bolt.

3. Engine mounting bolts are loose. 3. Tighten the engine mounting bolts.

4. Loose engine pulley, idler pulley, or blade

pulley.

4. Tighten the appropriate pulley.

5. Engine pulley is damaged. 5. Contact an Authorized Service Dealer.

Abnormal vibration

6. Blade spindle is bent. 6. Contact an Authorized Service Dealer.

1. Drive belt is worn, loose or broken. 1. Check the belt tension.

2. Drive belt is off pulley. 2. Install drive belt and check adjusting

shafts and belt guides for correct position.

3. Deck belt is worn, loose or broken. 3. Install new deck belt.

4. Deck belt is off pulley. 4. Install deck pulley and check the idler

pulley, idler arm and spring for correct

position and function.

Blades do not rotate.

5. Broken or missing idler spring.

5. Replace the spring.

42