Maintenance

Change Fuel Filter

Service Interval: As required

A fuel lter is installed between the fuel tanks and the

engine. Replace when necessary.

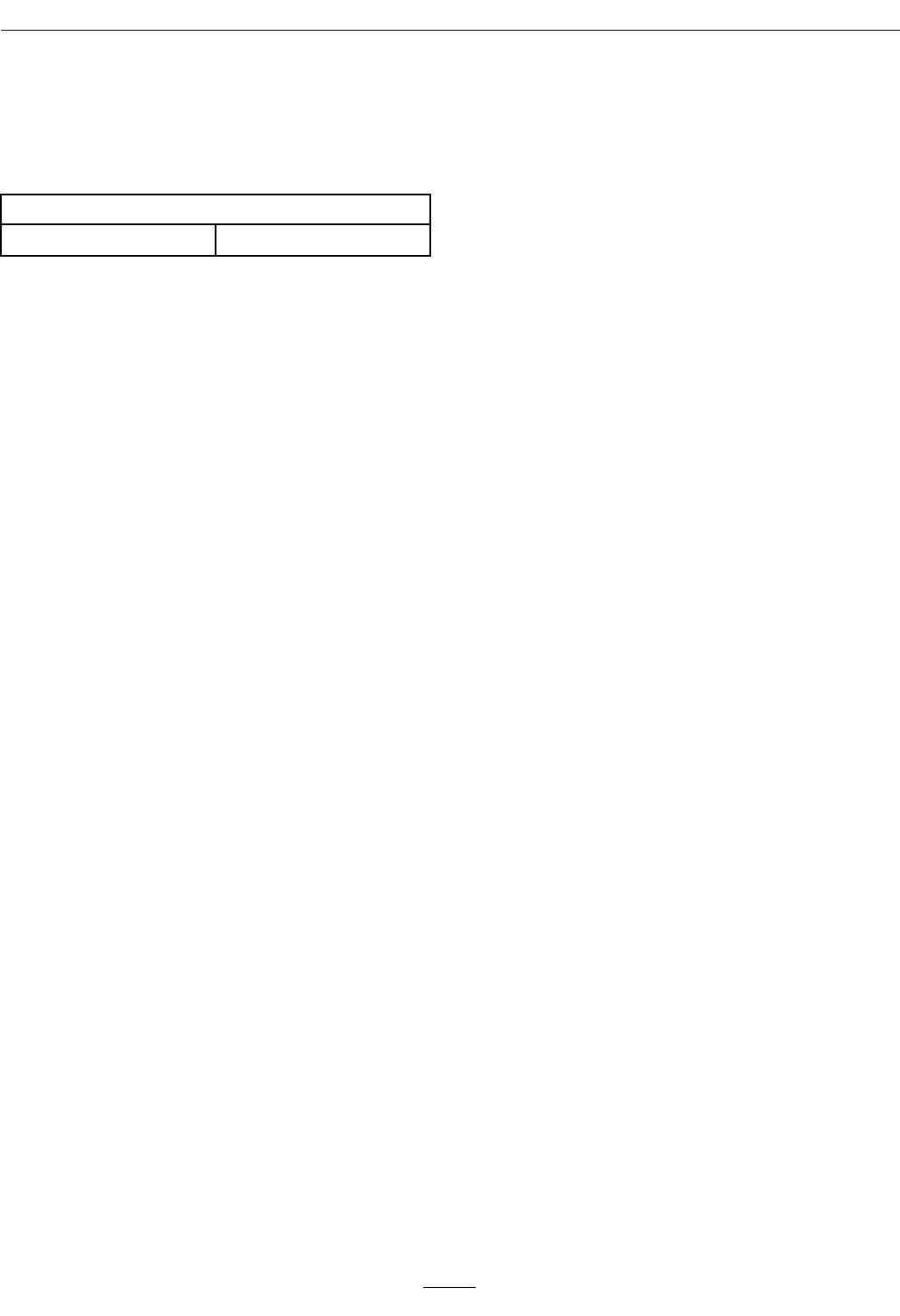

Replacement Filters

Kohler

Kohler P/N 2405010

Change Hydraulic System

Filter

Service Interval: After the rst 250 hours

Yearly thereafter

Note: Use only Exmark Part No. 109-4180 for

summer use above 32°F (0°C) or Part No. 1-523541

for winter use below 32°F (0°C).

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Raise seat.

3. Carefully clean area around lter. It is important

that no dirt or contamination enter hydraulic

system.

4. Unscrew lter to remove and allow oil to drain

from reservoir.

Important: Before reinstalling new lter, ll

it with Mobil 1 15W-50 and apply a thin coat

of oil on the surface of the rubber seal.

Turn lter clockwise until rubber seal contacts the

lter adapter, then tighten the lter an additional

2/3 to 3/4 turn.

5. Fill reservoir as stated in Check Hydraulic Oil

Level section.

6. Raise the rear of machine up and support with

jack stands (or equivalent support) just high

enough to allow drive wheels to turn freely.

7. Start engine and move throttle control ahead to

full throttle position. Move the speed control

levers to the full speed and run for several

minutes. Shut down machine and recheck oil

level.

Note: Do Not change hydraulic system oil (except

for what can be drained when changing lter), unless

it is felt the oil has been contaminated or been

extremely hot.

Changing oil unnecessarily could damage hydraulic

system by introducing contaminates into the system.

Wheel Hub - Slotted Nut

Torque Specication

Service Interval: After the rst 100 hours

Every 500 hours thereafter

When tightening the slotted nut on the wheel motor

tapered shaft:

1. Torque the slotted nut to 125 ft-lb (169 N-m).

2. Check distance from bottom of slot in nut to

inside edge of hole. Two threads (0.1 inch) or less

should be showing.

3. If more than two threads (0.1 inch) are showing

remove nut and install washer (P/N 1-523157)

between hub and nut.

4. Torque the slotted nut to 125 ft-lb (169 N-m).

5. Then tighten nut until the next set of slots line up

with the cross hole in shaft.

6. Replace cotter pin.

Note: Do Not use anti-seize on wheel hub.

Fuel Tank — Mounting

Hardware Specications

Service Interval: As required

When installing the nuts on the fuel tank studs, fully

tighten the nyloc nut and back off 1/2 turn. This

allows for normal fuel tank expansion and contraction

with changes in temperature and fuel levels.

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242”

or “Fel-Pro, Pro-Lock Nut Type” are used on the

following fasteners:

• Pump drive sheave set screws.

• Square head setscrews on Hydro pump control

arms.

• Sheave retaining bolt in the end of engine

crankshaft.

32