Operation

deck lift assist lever located at the front right

corner of the oor pan.

Note: When changing the cutting height

positions, always come to a complete stop

and disengage the PTO.

Figure 8

1. Lever in transport and 5 inch (12.7 cm) cutting height

position

4. Insert the height adjustment pin into the hole

corresponding to the desired cutting height and

install the hairpin cotter pin.

See the decal on the side of the deck lift plate for

cut heights.

5. Move the deck height lever out of the transport

position (or 5 inch (12.7 cm) cutting height) and

down onto the height adjustment pin to mow at

selected height.

Note: The foot operated deck lift assist lever

can be used to momentarily lift the deck to clear

objects. Be sure that PTO is disengaged.

Adjusting the Anti-Scalp Rollers

It is recommended to change the anti-scalp roller

position, when the height of cut has changed.

1. Stop the machine and move the motion control

levers outward to the neutral locked position.

2. Disengage the PTO.

3. Engage the park brake.

4. Stop the engine, remove the key and wait for all

moving parts to stop.

5. After adjusting the height of cut, adjust the

anti-scalp rollers by removing the nyloc nut,

bushing, spring disc washer and whizlock nut.

6. Place the rollers in one of the positions shown

(Figure 9). Rollers will maintain 3/4 inch (19 mm)

clearance to the ground to minimize gouging and

roller wear or damage.

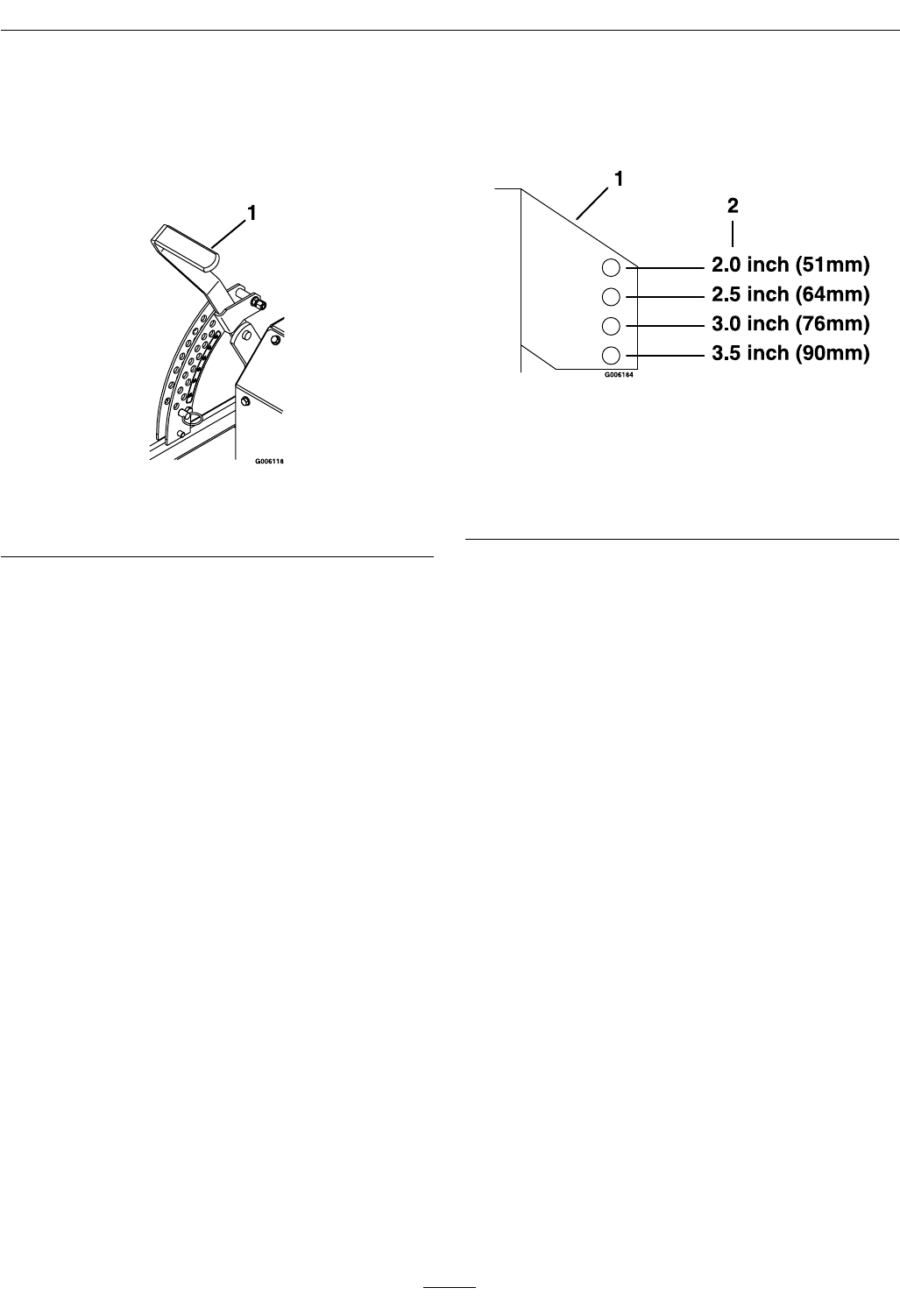

Figure 9

For cutting heights above 3.5 inches (90 mm) use the

bottom hole. The rollers will still be effective against

scalping.

1. Anti-scalp roller

mounting bracket

2. Cutting height

For Maximum Deck Flotation, place the rollers

one hole position lower. Rollers should maintain

1/4 inch (6.4 mm) clearance to the ground. Do

Not adjust the rollers to support the deck.

7. Be sure the whizlock nuts are installed with the

spring disc washer between the head of the nut

and the mounting bracket.

Note: The foot operated deck lift assist lever

can be used to momentarily lift the deck to clear

objects. Be sure that PTO is disengaged.

8. Torque the 3/8–16 whizlock nut to 30-35 ft-lb

(41-47 N-m) (Figure 10).

9. Torque the 3/8 nyloc nut to 30–35 ft-lb (41-47

N-m).

22