TOREMOVEWHEELFORREPAIRS

• Block up axle securely.

• Remove axle cover, retaining ring and

washers to allow wheel removal (rear

wheel contains a square key - Do not

lose).

• Repair tire and reassemble.

• On rear wheels only: align grooves in

rear wheel hub and axle. Insert square

key.

• Replace washers and snap retaining

ring securely in axle groove.

• Replace axle cover.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, tire sealant

may be purchased from your local parts

dealer. 13re sealant also prevents tire dry

rot and corrosion.

WashersA

RetainingRing _ ff/'__

SquareKey _' "_'_"

(Rear Wheel Only)

TO START ENGINE THAT HAS A WEAK

BATTERY

_CAUTION: Lead-acid batteries gener-

ate explosive gases. Keep sparks, flame

and smoking materials away from batter-

ies. Always wear eye protection when

around batteries.

If your battery is too weak to start the

engine, it should be recharged. If "jumper

cables" are used for emergency starting,

follow this procedure:

IMPORTANT: Your tractor is equipped

with a 12 volt negativ e grounded system.

The other vehicle must also be a 12 volt

negative grounded system. Do not use

your tractor battery to start other vehicles.

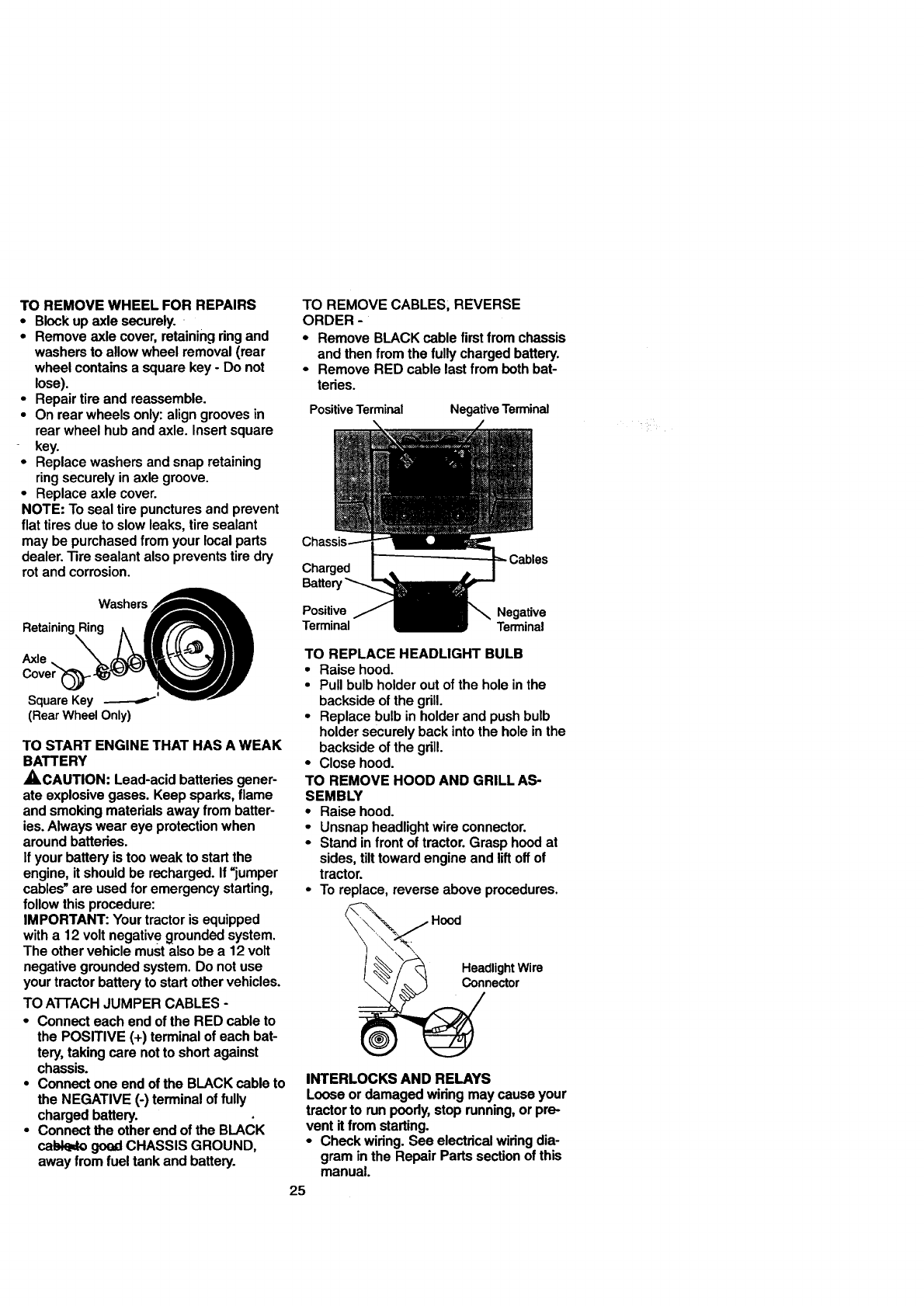

TO ATTACH JUMPER CABLES -

• Connect each end of the RED cable to

the POSITIVE (+) terminal of each bat-

tery, taking care not to short against

chassis.

• Connect one end of the BLACK cable to

the NEGATIVE (-) terminal of fully

charged battery.

• Connect the other end of the BLACK

cabk_to goed CHASSIS GROUND,

away from fuel tank and battery.

TO REMOVE CABLES, REVERSE

ORDER -

• Remove BLACK cable first from chassis

and then from the fully charged battery.

- Remove RED cable last from both bat-

tedes.

Positive Terminal

NegativeTerminal

Charged

Ballet

Positive Negative

Terminal Terminal

TO REPLACE HEADLIGHT BULB

• Raise hood.

• Pull bulb holder out of the hole in the

backside of the grill.

• Replace bulb in holder and push bulb

holder securely back into the hole in the

backside of the gdll.

• Close hood.

TO REMOVE HOOD AND GRILL AS-

SEMBLY

• Raise hood.

• Unsnap headlight wire connector.

• Stand in front of tractor. Grasp hood at

sides, tilt toward engine and liftoff of

tractor.

• To replace, reverse above procedures.

\

Headlight Wire

Connector

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your

tractor to run poody, stop running, or pre-

vent itfrom starting.

• Check wiring. See electrical widng dia-

gram in the Repair Parts section of this

manual.

25