21

front of the unit (not the operator’s posi-

tion). If the belt tension is correct, reinstall

the belt cover and secure it with the two

nuts.

• If the guide mark is aligned with the

guide pin, or moves to the right side of the

guide pin, then the belt is too loose and the

tension must be readjusted as described

next.

3. The reverse idler pulley (L, Figure 5-13)

regulates the tension that is applied to the

reverse drive belt (P). The following ad-

justment will allow the reverse idler pulley

to apply more tension to a loose belt.

4. Remove the belt cover.

5. Slip the reverse belt (P, Figure 5-13) off

the engine-driven reverse (upper) pulley.

6. On the right side of the unit (as viewed

from operator’s position), remove the hair-

pin cotter from the clevis pin (R, Figure 5-

13) that connects the reverse idler arm (K)

to the reverse adjustable link. Push inward

on the reverse idler arm (K) and remove

the clevis pin (R).

7. There are two holes in the reverse ad-

justable link (S, Figure 5-15). Push inward

on the reverse idler arm (K) and install the

clevis pin (R) through the inner hole in the

reverse adjustable link (S) and out through

the single hole in the reverse idler arm (K).

Secure the clevis pin with the hairpin cot-

ter.

8. Reinstall the reverse belt (P, Figure 5-13)

on the reverse (upper) pulley, making sure

the belt is located to the inside of the re-

verse idler pulley (L, Figure 5-13).

9. Reinstall the belt cover and secure it

with the two nuts.

IMPORTANT:

If, in future tests for

reverse belt tension, the guide mark

should again align with or move to the

right side of the guide pin, it means that

the reverse belt is worn beyond

adjustment. Before installing a new belt,

you must return the clevis pin to the

OUTSIDE hole in the reverse adjustable

link.

Forward Drive Belt Removal

and Installation

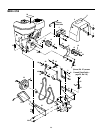

This model has two forward speeds (High

and Low) and one reverse speed. The for-

ward engine pulley (D, Figure 5-16) has

two grooves for the two forward speeds.

The reverse engine pulley (A, Figure 5-16)

has one groove for the one reverse speed.

The transmission pulley (C, Figure 5-16)

has three grooves. The groove closest to

the engine is for the reverse belt. The mid-

dle groove is for the High speed forward

belt range; the rearmost groove is for the

Low speed forward belt range.

A. Removing the Forward Drive Belt:

1. Stop the engine, allow it to cool and dis-

connect the spark plug wire before work-

ing near the belts.

2. Remove the reverse drive belt

following the Removing the Reverse Drive

Belt instructions in this section.

3. Move the forward drive belt (B, Figure

5-16) completely off the engine forward

drive pulley (D).

4. Slip the forward drive belt completely

off the transmission drive pulley (C, Figure

5-16) by moving it to the front of the pul-

ley.

5. Pull the forward drive belt up and off the

pulleys by feeding the bottom half of the

belt in between the engine and transmis-

sion pulleys.

B. Installing the Forward Drive Belt:

1. The reverse drive belt must be removed

before installing the forward drive belt.

2. Slip the forward drive belt down between

the rear of the engine forward drive pulley

(D, Figure 5-16) and feed the bottom half in

between the engine and transmission pul-

leys (see Figure 5-17). Be sure that the belt

is to the inside of the forward idler pulley

and forward belt guide (see J and I, Figure

5-12).

Figure 5-17: Install forward drive belt over

rear of engine forward pulley and bring lower

half of belt down and in front of transmission

pulley.

Figure 5-15: Installing clevis pin in inside hole

of reverse adjustable link.

Figure 5-16: Belt drive system.

WARNING: Before inspecting, cleaning or servicing the machine, shut off engine, wait for all

moving parts to come to a complete stop, disconnect spark plug wire and move wire away from

spark plug. Failure to follow these instructions can result in serious personal injury or property

damage.

S

R

K

DB

A

C

FRONT