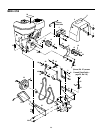

19

WARNING: This is a CRT

(counter-rotating tine) tiller

and its tines must be mounted

in the direction shown in

Figure 5-7. Failure to comply

could result in personal injury

or property damage.

2. When installing individual tines, install

them in the reverse order from which they

were removed. The two sets of inboard

tines are installed so one tine faces to-

ward the transmission housing and the

other tine faces away from it. The single

outboard tine on each side faces toward

the transmission housing. Also be sure

the cutting edges face so they will enter

the soil first when the tiller is moving for-

ward–this means the cutting edges face

toward the operator position.

Checking And Adjusting Tension

On Drive Belts

While checking belt tension, also check

for cracks, cuts or frayed edges. A belt

that is in poor condition should be re-

placed.

WARNING: Follow the

belt adjustment instructions

carefully. An incorrect

adjustment could result in the

Forward Clutch mechanism

engaging too soon. This could

cause loss of tiller control and

result in personal injury or

property damage.

Maintaining correct tension on the drive

belts is important to good tilling perfor-

mance and long belt life. A loose belt will

slip on the engine and transmission pul-

leys and cause the tines and wheels to

slow down – or stop completely – even

though the engine is running at full speed.

A loose belt will also result in premature

wear to the belt.

The tension on a new forward drive belt

should be checked after the first two (2)

hours of operation. Thereafter, check the

tension after every ten (10) hours of

operation.

The reverse drive belt, because it is used

infrequently, will not require an initial ten-

sion adjustment until a significant num-

ber of operating hours has passed.

To Check and Adjust Tension on the Forward

Drive Belt:

1. Checking for correct belt tension is the

same as that described in item 5, Step 4:

Attach Forward Clutch Rod. Before check-

ing, shut off the engine, disconnect the

spark plug wire, and allow the engine and

muffler to cool down. If, after following

the adjustment procedures, you cannot

get the correct gap on the forward clutch

rod adjustment bracket, you will need to

make a secondary adjustment as de-

scribed next.

2. Disconnect the Forward Clutch Rod (A,

Figure 5-9) from the swivel plate (B) by

removing the innermost hairpin cotter

(C).

3. Unthread the Forward Clutch Rod (in a

counterclockwise direction as viewed

from the front of the unit) until one or two

threads on the rod extend above the rect-

angular nut (D, Figure 5-10) on the for-

ward clutch bracket.

4. Remove the belt cover.

5. Slip the forward drive belt (E, Figure

he engine-driven forward drive pulley by

pushing it off (away from engine) with

your left hand while pulling engine starter

rope with your right hand.

6. On the left side of the unit (from oper-

ator’s position) remove the hairpin cotter

from the clevis pin (F, Figure 5-11) that

connects the forward idler arm (G) to the

forward adjustable link (H). Push inward

on the forward idler arm (G) and remove

the clevis pin (F).

7. There are two holes in the forward ad-

justable link (H, Figure 5-11). Push in-

ward on the forward idler arm (G) and

install the clevis pin (F) through the inner

hole in the forward adjustable link (H) and

out through the single hole in the forward

idler arm (G). Secure the clevis pin with

the hairpin cotter.

Figure 5-7: Complete tine assemblies— holders, tines and hardware.

WARNING: Before inspecting, cleaning or servicing the machine, shut off engine, wait for all

moving parts to come to a complete stop, disconnect spark plug wire and move wire away from

spark plug. Failure to follow these instructions can result in serious personal injury or property

damage.

ENGINE

TINE

SHAFT

DENOTES CUTTING EDGE

OF TINE

C

D

A

B