7 - 26

16.Remove the motor shaft, washers and bypass

plate from the center section and inspect for

unusual wear or damage.

Inspect the center section running surfaces for unusual

wear or damage.

17.Remove the pump block assembly, block thrust

washer and spring from the input shaft and inspect

for unusual wear or damage. The pistons should fit

with very little side clearance in the block bores,

but must slide freely.

NOTE:

The correct bore diameter for the block is

0.6295 to 0.6303 and the pistons should be 0.6288 to

0.6291.

18.Remove the motor thrust bearing assembly

swashplate kit and cradle bearing from the housing

and inspect for unusual wear or damage.

19.Remove the slot guide from the displacement

control shaft.

20.Remove the bypass actuator from the housing.

21.Reposition the housing and remove the input shaft

lip seal from the housing bore. A hook type tool

may be used to pry the seal out. Care must be

taken to avoid damage to the housing bore, shaft

sealing surface or bearing. Once removed, the seal

is not reusable.

22.Remove the input shaft bearing ring.

23.Remove the pump input shaft assembly from the

housing.

24.Inspect the shaft and bearing for unusual wear or

damage.

25.Reposition the top housing and remove the

displacement control shaft and lip seal. Inspect the

housing for damage.

7.4 REPLACEMENT OF PARTS

All parts should be thoroughly cleaned in a suitable

solvent. All sealant material MUST be removed from

the housing prior to reassembly.

Inspect all parts for damage, nicks or unusual wear

patterns. Replace all parts having unusual, excessive

wear or discoloration.

Inspect the sealing surfaces, bearing surfaces, and

shaft splines. Polish the sealing areas on the shafts if

necessary.

Replace any worn or damaged parts

.

The running surfaces of the cylinder blocks

MUST

be

flat and free from scratches. If scratches or wear are

found on the running surface of the cylinder block or

center section, polish or replace the parts, When

polishing these surfaces, up to 0.0004" may be

removed. If this is not sufficient to obtain a flat surface

free of scratches, the part should be replaced.

Clean and lightly oil parts prior to assembly of the IHT.

Be sure to torque all threaded parts to the

recommended torque levels.

Replace all o-rings and shaft seals.

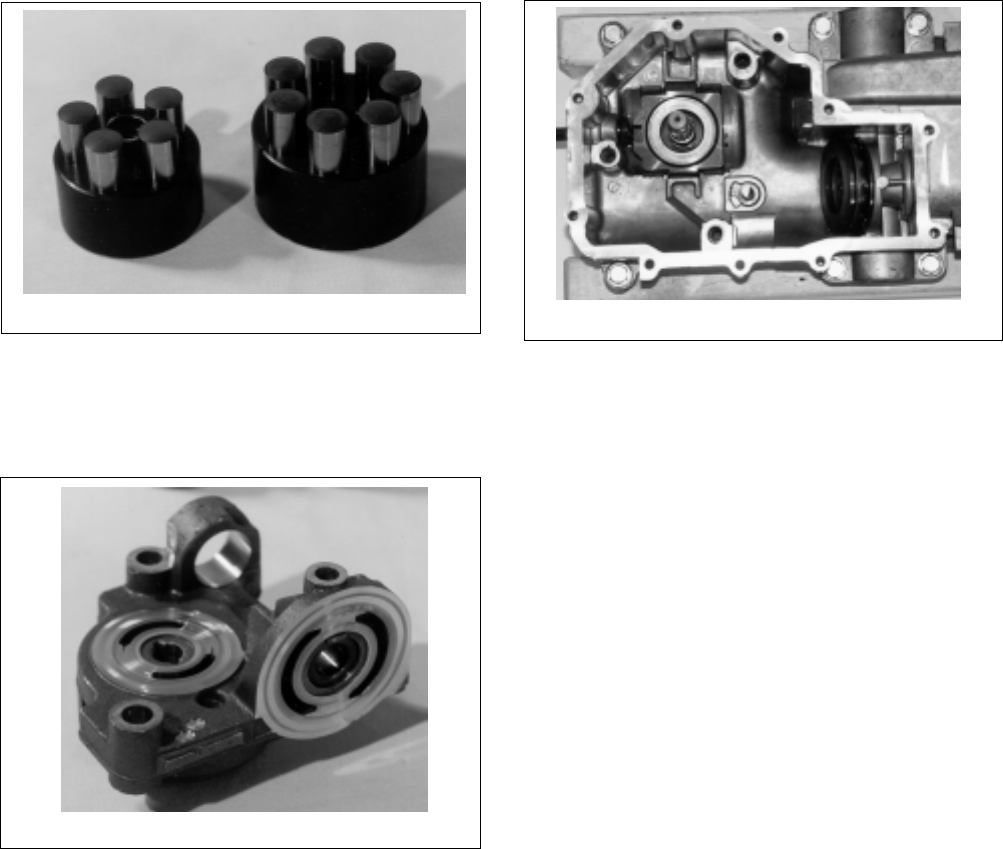

Figure 25

Figure 26

Figure 27