© 2005 Alamo Group Inc.

Section 7 - 5

Switch Blade (JD-5105-5205-5225-5325-5425-5525, Asy. Man) 05/05

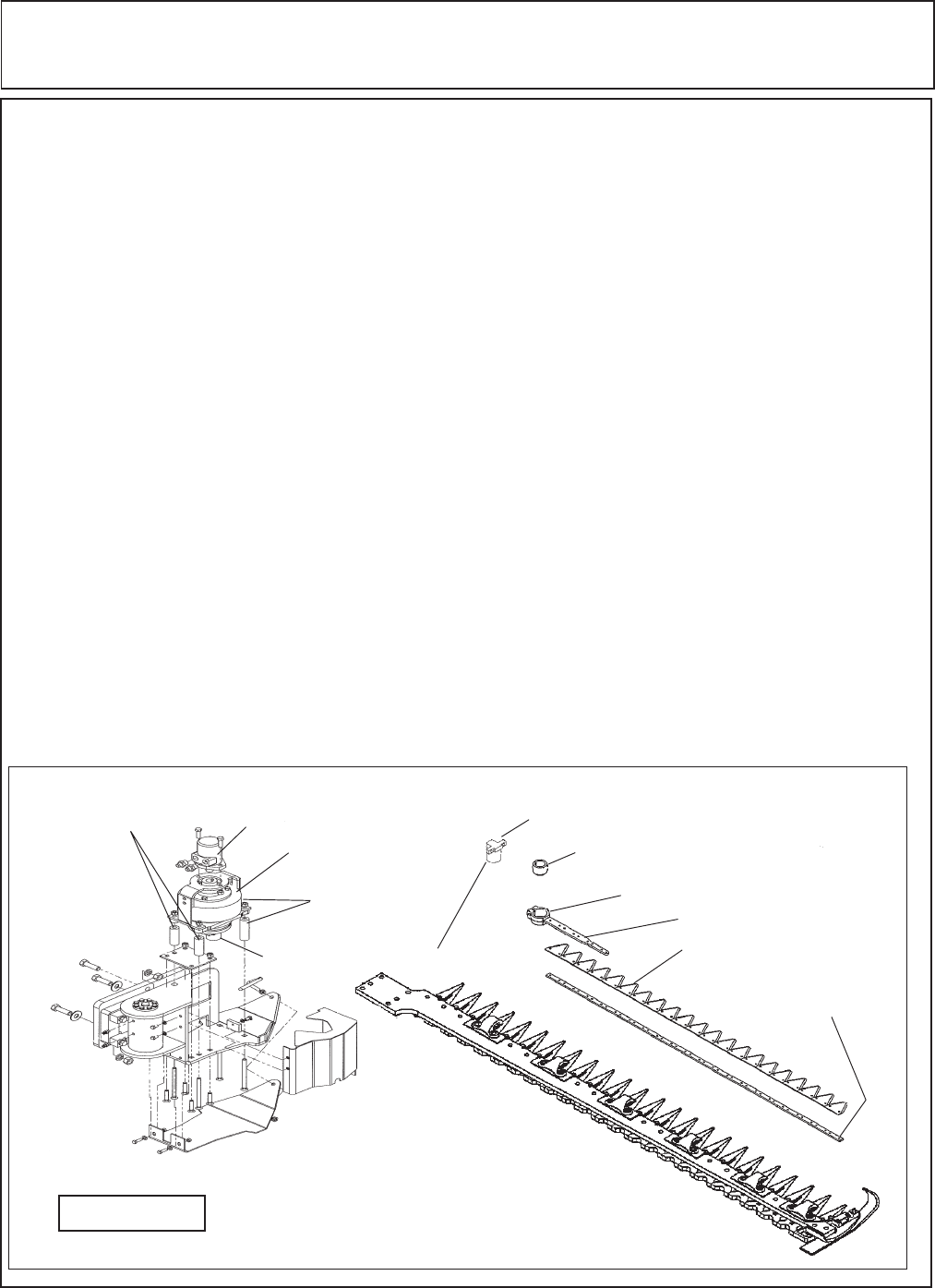

CUTTER BAR REPLACEMENT

Cutter Bar Assembly Replacement:

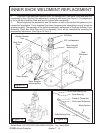

Replacement of the complete cutter bar assembly will require the cutter bar assembly to be

unbolted from skid shoe / break-a-way assembly. Wear gloves as the knives on the cutter bar can be

very sharp and can cut you. (See Figure 10)

It will not be require to remove any of the hydraulic hoses or even take them loose. Looking down

at the planetary drive (and Hydraulic Motor Assembly) there are four nuts in the plate that is attached to

the drive assembly. Remove these four nuts, if you want to remove the four carriage bolts the skid shoe

will have to be unbolted and removed. When lifting the drive assembly up and away from the cutter bar

take notice of the four tube spacers under the drive assembly, there are two different length of the

spacers. The short ones go to the rear and the long ones go to the front. Once the drive assembly has

been lifted off you will see a nylon bearing in the knife bar head clamp, it should have stayed in the clamp.

There will be two more bolts connecting cutter bar to break-a-way assembly once these nuts

are removed the cutter bar should lift up over the bolts if they were left in. There will be a square plate

under the cutter bar that has 4 holes in it, make certain to note this for reassembly

When reinstalling cutter bar reverse the disassembly procedures. Make certain the nylon

bearing is in good condition or replaced, sometimes the clamp will have to be loosened to get the nylon

bushing installed into clamp and the drive stud that is attached to the drive assembly with two socket

head bolts, DO NOT tighten clamp bolt now. This drive stud can be unbolted from drive assembly,

inserted into nylon bearing and re-bolted to drive assembly later.

The nuts on the carriage bolts (4 short and 2 long 3/4" carriage bolts) that retain the drive

assembly and the cutter bar to the break-a-way assembly must be torqued to 85 ft. lbs.

After the assembly is finished the guards, clips and ledger must be checked, see the previous

section in this manual for setting cutter bar components.

Tighten the clamp bolt around the drive stud, use a good thread lock compound on clamp bolt

and tighten the clamp bolt until the up & and down movement of clamp on drive stud is removed. DO

OVER TIGHTEN the clamp bolt as the drive stud has a bearing inside that will be damaged.

Short Tube

Spacers

Long Tube

Spacers

Planetary Drive

Assembly

Motor

Figure 10

Nylon Bearing

Knife Drive Stud Assembly

Clamp & Clamp Bolt

Knife Backing Strip

Blade Sections

Knife Head Weldment

Knife Drive Stud Assembly