26

15

MAINTENANCE INSTRUCTIONS (continued) SAFETY SIGNS

W ARNING!

When attaching the driveline yoke to the tractor

PTO shaft, it is important that the spring activated

locking collar turns freely and that the locking pin is

seated on the PTO shaft groove. A loose yoke could

slip off and result in personal injury or damage to the

mower.

W ARNING!

Avoid personal injury! Always support or block the

mower when servicing the blades, carrier or any

other component on the underside of the deck.

The metal telescoping drive tubes inside the plastic

shield tubes must be lubricated before each use. See

figure 11.

Disconnect the driveline from the tractor and pull halves

apart (do not disconnect the driveline that is attached to

the mower gearbox). Insert grease into drive tube and

spread it evenly. Reconnect the two driveline halves

together. Reconnect the driveline to the tractor PTO,

raise and lower the mower several times so that the

grease just applied spreads over the entire working area

of the drive tubes.

DRIVELINE LUBRICATION

Grease fittings are located on the cross and bearing kit

assemblies of both U-joints. U-joints should be greased

after every 8 hours of operation. See figure 10 for the

location of the grease fittings. Do not force grease

through the needle bearing cup assemblies.

BLADE SPINDLE LUBRICATION

Blade spindles must be lubricated after every 8 hours of

operation. Access the lubrication fittings through the

holes in the belt guards. Each spindle is supplied with a

grease fitting on top, and it must be lubricated sufficiently

so that a small amount of grease escapes through the

bleed hole on their underside. Do not force large

amounts of grease on the spindles, as it may get on the

drive belts.

BLADE SERVICING

Use only correct specified blades on your mower. They

are manufactured of special heat-treated alloy steel.

Substitute blades may not meet specifications and may

fail in a hazardous manner, which could cause injury.

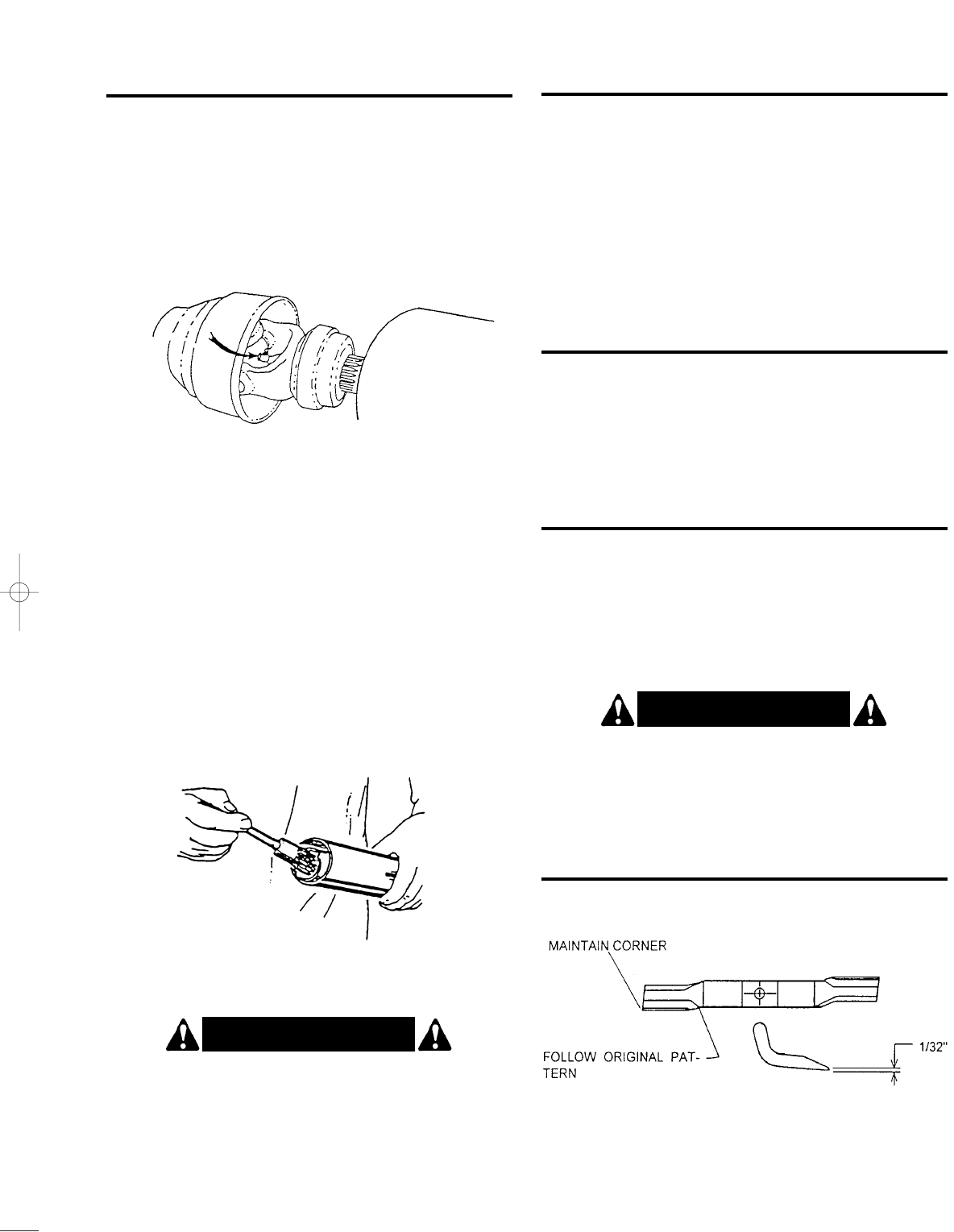

BLADE SHARPENING

To maintain a proper blade balance, always sharpen

both ends of the blade equally. Follow the sharpening

pattern as shown on figure 12. Do not sharpen the

blades to a razor edge, but leave a

1

/

32

” blunt edge.

Never sharpen the back side of the blades.

BLADE REMOVAL

Hold the end of the blade using heavy leather gloves

and remove the left hand threaded bolt.

Figure 10

Figure 11

Figure 12

ITEM 1 – Part No. 101103

ITEM 2 – Part No. 101173

DANGER

THROWN OBJECT HAZARD

To prevent serious injury or death:

• Do not operate unless all guards

are installed and in good condition.

• Stop blade rotation if bystanders

come within several hundred feet.

M600

ITEM 8 – Part No. 101101

WARNING

OPERATE THIS MACHINE AT

540 RPM

TRACTOR PTO SPEED ONLY

Overspeeding PTO may cause component

failure with resulting injury.

ITG 100

DANGER

ROTATING DRIVELINE HAZARD

To prevent serious injury or death from

rotating driveline:

• Keep all guards in place when operating.

• Operate only at 540 RPM.

• Keep hands, feet, hair and clothing away

from moving parts.

SW104

Replace Safety Signs

if Damaged or Missing!

26 / 15 - FM001 12/6/00 3:40 PM Page 1