16

25

SAFETY SIGNS

MAINTENANCE INSTRUCTIONS

W ARNING!

Always disengage the tractor PTO before raising

the mower for transport or making adjustments.

LUBRICATION

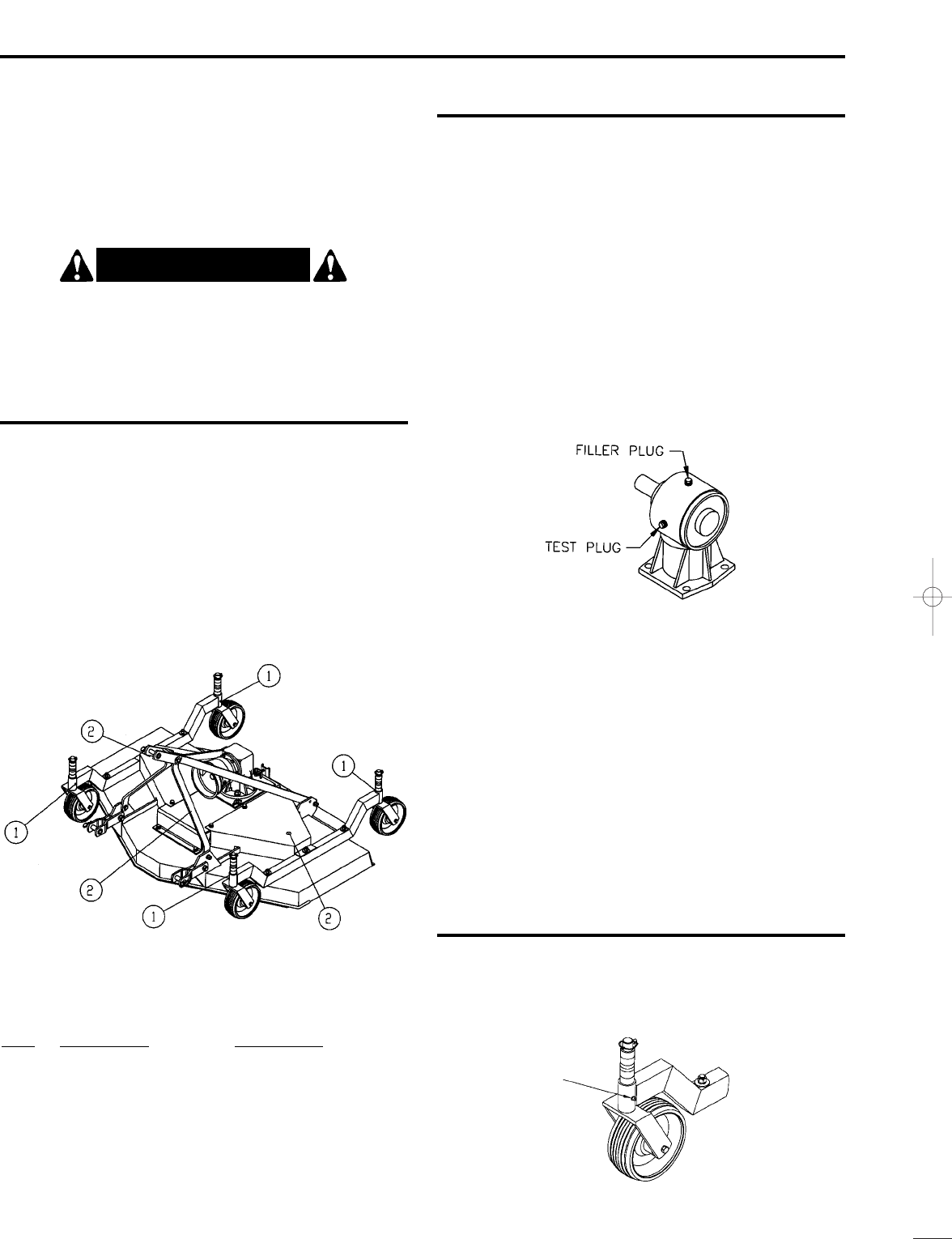

Do not let excess grease collect on or around parts, par-

ticularly when operating in sandy areas. The illustration

below and on the next pages, show the location of all the

lubrication fittings.

Use an SAE multi-purpose, lithium type grease for all

the locations shown on figure 7. Be sure to clean the

grease fittings before applying any grease. Daily lubrica-

tion of the driveline U-joints is necessary. Failure to main-

tain proper lubrication will result in premature wear and

damage to the U-joints, gearbox and/or driveline.

Note:

1. It is recommended that the test plug be removed after

every 8-10 hours of operation, and oil added to the

proper fill level if required.

2. Do not overfill the gearbox with oil. This will result in

pressure build up inside the unit, which can cause the

oil seals to leak.

3. If the gearbox suddenly starts making an unusual

noise, stop at once, check for oil leaks and refill it as

required.

GEARBOX LUBRICATION

The gearbox must be filled with SAE 90 EP oil

before operating.

To fill gearbox to the correct operating level:

1. Place the mower on an even and leveled surface.

2. Remove filler and test level plug (see figure 8 for

location of plugs).

3. Add oil through the filler plug until it starts running out

of the test plug. (Pour oil slowly to make sure that the

lower portion of the gearbox housing has been filled)

4. Screw the test and filler plugs back in their corre-

sponding places.

It is recommended that the oil level plug be removed

after every 8-10 hours of operation and oil added until it

runs out of the test plug hole. The filler plug hole and test

plug hole are both located on the back of side of the

gearbox.

GAUGE WHEEL ASSEMBLIES

The gauge wheels are equipped with bearings which

require grease regularly. Grease fittings are provided in

the gauge wheel pivot. It is recommended that these be

lubricated after every 8 hours of operation. See figure 9.

Figure 7

Lubrication fitting location

Item Description Frequency*

1 Gauge wheel pivots Every 8 hours or daily

2 Blade spindle Every 8 hours or daily

N/S U-joints Every 8 hours or daily

* Lubrication intervals shown are for mowers operating

under normal conditions. Severe or unusual condi-

tions may require more frequent lubrication.

Before operating the mower, make sure that it is

properly lubricated and thoroughly inspected. Only a

minimum of time and effort is required to regularly

lubricate and maintain it. Following a regular program will

provide long life and trouble free operation.

Figure 8

Figure 9

ITEM 3 – Part No. 101176

WARNING

To prevent serious injury or death:

Si no lee ingles, pida ayuda a alguien que si lo lea para

que le traduzca las medidas de seguridad.

• Read and understand Operator’s Manual before using.

Review annually.

• Do not permit riders on the tractor or mower. Never

carry children on tractor seat.

• Do not allow children to operate mower.

• Operate only with guards installed and in good condition.

• Keep away from moving parts.

• Operate only with tractor equipped with ROPS and

seatbelts.

• Before mowing, clear debris from mowing area.

• Do not operate in the raised position.

• Stop engine, set brake and wait for all moving parts to

stop before dismounting.

• Support mower securely before working beneath unit.

• Transport with clean reflectors, SMV and working lights

as required by federal, state, and local laws.

M100

ITEM 4 – Part No. 101157

16 / 25 - FM001 12/6/00 3:28 PM Page 1