20 Dealer Service

51642 (Rev. 11/9/2007)

Blade Spindle Assembly (Figure 13)

Bearing cones and cups are designed to work together.

It is important to position them so bearing cone taper

mates with cup taper.

Lubricate new cups with a light oil. Place them in spin-

dle housing so they will mate with bearing cones. Cups

and cones are a press fit to minimize wear.

Seat cups securely with a press or place a large drift in

the flat lip and drive cups into housing until they seat

against machined shoulder of housing.

Place bottom bearing cone onto spindle shaft with

taper positioned to mate with cup. Press onto shaft and

seat on bottom shoulder of shaft.

Insert shaft and bearing through bottom of housing.

Fill housing cavity with a medium grade grease.

Install top bearing on shaft to mate with top cone.

Apply a thin coat of Permatex to shaft area where

sleeve will seat. Install sleeve on shaft and press

sleeve and bearing into housing until all free play is

removed and there is a very light drag on bearings

(similar to adjusting front wheel bearings on an auto-

mobile). Check by spinning spindle. It should turn

freely.

Be careful not to overtighten bearings. Proper bearing

adjustment is essential to good bearing life. Should you

overtighten bearings, hold spindle housing and rap

spindle shaft with a lead hammer.

Place a rag over bearings to protect them and drill a

3/16" hole 9/32" down from top of sleeve and drive roll

pin through sleeve and shaft to hold bearing adjust-

ment. Make sure roll pin does not extend past outer

diameter of sleeve on either side.

NOTICE

■ Improper positioning of seals can cause seal

damage.

Proper seal installation is important. An improperly

installed seal will leak and could cause bearing failure.

Pull the rubber portion of seal back and locate spring.

Lightly coat area of housing where seals seat with Per-

matex. Install bottom seal with spring up toward center

of housing.

Place seal squarely on housing and select a piece of

pipe or tubing with an OD that will set on outside edge

of seal. A tubing with an OD that is too small will bow

seal cage.

Carefully press seal into housing, preventing distortion

to metal seal cage. Seal should seat firmly and

squarely against machined shoulder in housing.

Make sure seal lip did not roll under. Distortion to seal

cage or damage to seal lip will cause seal to leak.

Damaged seals must be replaced.

Carefully press top seal in with spring up away from

center of housing. Top seal should be flush with, to

1/16" above, housing.

Lubricate spindle with a medium grade grease. Rotate

housing on spindle shaft, checking for free movement.

Blade Spindle Installation

Install spindle through bottom of mower and install four

mounting bolts. Be sure to position grease fittings

toward lubrication access areas.

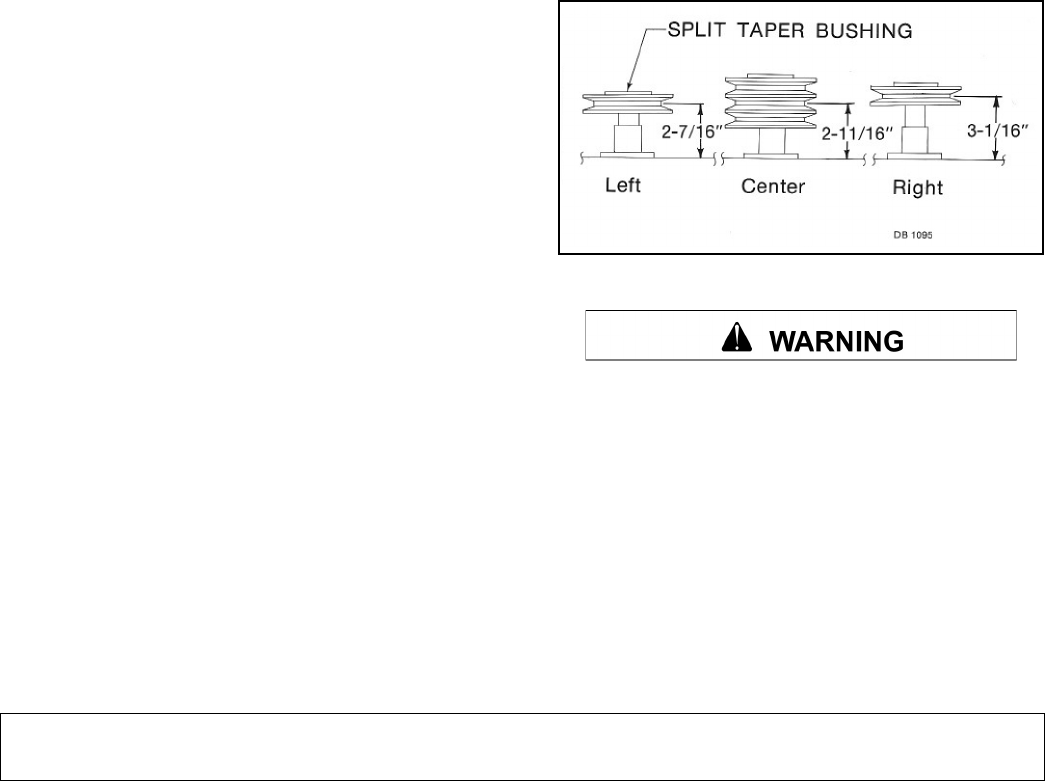

Blade Spindle Pulley Installation

Insert bolts through unthreaded holes in bushing and

start into threaded holes of pulley. Install pulley, split

taper bushing and key to spindle shaft. Set pulley

dimension (see Figure 14) from top of mower frame

and alternately tighten bushing bolts. Continue alter-

nate tightening sequence until assembly is tight and all

bolts are torqued to 12 lbs-ft.

Figure 14. Belt Pulley Height Adjustments

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.