22

Maintenance Instructions LUBRICATION

LUBRICATION

Proper lubrication is an important maintenance pro-

cedure. It reduces wear and makes the machine

quieter and easier to operate.

Grease Fitting and Oil Point Lubrication

Lubricate the grease fittings and oil points after ev-

ery 25 hours of operation. Use SAE general pur-

pose lithium or molybdenum base grease for grease

fittings and light machine oil (SAE 10) to lubricate oil

points. Lubricate the locations shown in the

Snowblower Lubrication Points illustration.

PTO U-Joint

Lubricate the grease fitting for the PTO U-joint every

8 hours with SAE general purpose lithium or molyb-

denum base grease.

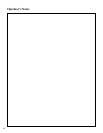

The PTO U-joint is accessed by removing the gear-

box cover. Two (2) bolts (one on each side) fasten

the gearbox cover to mounting tabs on the snow-

blower frame (refer to Snowblower with Gearbox

Cover Removed photo).

Gearbox Lubrication

The gearbox is permanently lubricated (oil filled) and

sealed requiring no scheduled lubrication. However,

the gearbox oil seal(s) should be checked every 25

hours for indication of an oil leak. If an oil leak is

noted, replace the oil seal and relubricate the gear-

box as follows:

1. Remove the gearbox following the procedure

described in Gearbox Replacement in RE-

PLACING/REPAIRING.

Snowblower with Gearbox Cover Removed

2. Clean the area around the gearbox cover plate

to prevent contaminants from entering the gear-

case.

3. Remove the screws securing the cover plate on

the gearbox.

4. Check the level of lubricant in the gearbox. If

the lubricant is low, add SAE E.P. (Extreme

Pressure) 90W oil until the oil level is up to (sub-

merges) the horizontal shaft in the gearbox

(shaft parallel to cover plate).

NOTE: In case the gearbox is completely

drained of oil, approximately 5 fl. oz. (15 cl) of oil

is required to refill the gearbox.

IMPORTANT: DO NOT overfill the gearbox.

The gearbox assembly is not vented, and over-

filling with oil will cause excessive pressure and

result in oil leaks.

5. Check the condition of the cover gasket and

replace if worn or damaged. Reinstall gearbox

cover plate; torque screws to 24 in-lb (2.7 N·m).

6. Reinstall the gearbox cover by reversing the re-

moval procedures.

WARNING

DO NOT attempt to lubricate the machine

with the tractor engine running. Disen-

gage the PTO clutch, shut off the ma-

chine, and remove the ignition key.

Gearbox Cover

Mounting Tabs