ASSEMBLY INSTRUCTIONS

OIL AND FUEL INFORMATION

4

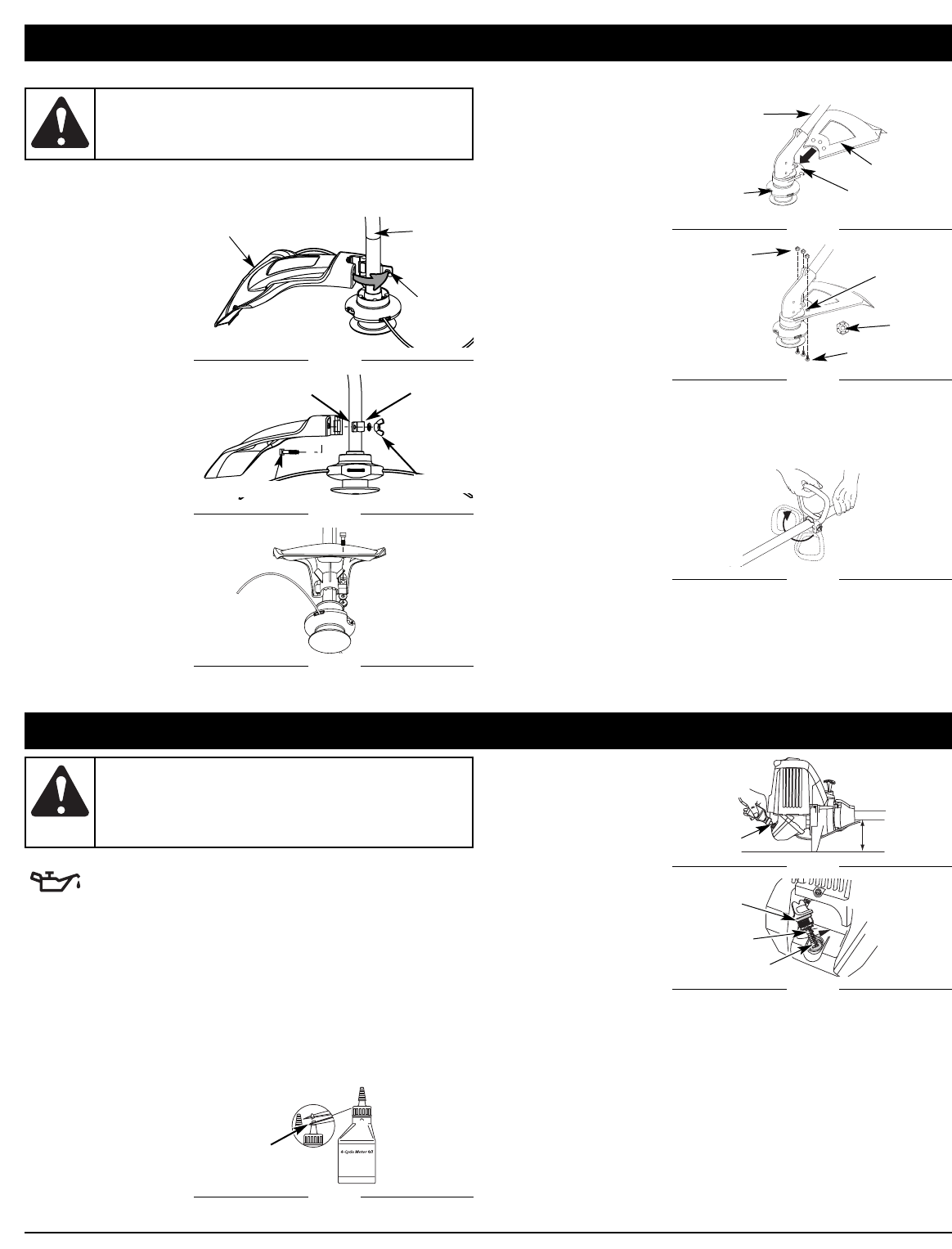

INSTALL CUTTING ATTACHMENT SHIELD

Use the following instructions if the cutting attachment shield on

your unit is not installed. Use only the instructions that apply to the

type of shaft and shield that your unit is equipped with.

TB415CS

1. Place the cutting

attachment shield

onto the shaft

housing. Be sure the

guard mounting

bracket slides into

the slot on the edge

of the cutting shield.

Rotate the shield

into place,

counterclockwise.

The holes in the

guard mounting

bracket and cutting

attachment shield

will line up (Fig. 1).

2. F

rom inside the cutting

attachment shield,

push the square bolt

through the hole until

the threaded end

protrudes through the

guard mounting

bracket (Fig. 2).

3. Put the washer on

the bolt, then screw

the wing nut onto the

bolt and tighten.

Figure 3 shows the

installation process from underneath the unit.

WARNING:

To prevent serious personal injury, never

operate the trimmer without the cutting attachment

shield in place.

Fig. 1

Shaft

Housing

Guard

Mounting

Bracket

Cutting Attachment

Shield

Guard Mounting

Bracket

Washer

Wing Nut

Square Bolt

Fig. 2

Square Bolt

Fig. 3

TB465SS

1. Slide the cutting attachment shield into the shield mount on the

cutting attachment.

Align the screw holes

in the shield with the

holes in the cutting

attachment (Fig. 4).

2. Place a hex lock nut

into one of the three

recessed holes on

the top of the

cutting attachment

shield (Fig 5).

3.

Install a screw into the

hole from the bottom

of the cutting

attachment shield and

screw it into the nut

installed in step 2 (Fig.

5). Do not tighten.

4. Repeat steps 2 and

3 until all three screws have been started, then tighten securely.

ADJUSTING THE D-HANDLE

1. Locate the wing nut on the D-Handle. Loosen the wing nut

enough to loosen the

D-Handle (Fig. 6).

NOTE: Do not remove

wing nut,

washer, or bolt.

2. Rotate the D-Handle

to the upright

position on the front

side of the shaft

housing (Fig. 6).

NOTE: The D-handle should slant towards the powerhead of the

unit.

3. Hold the unit in the operating position (Fig. 15). If necessary,

reposition the D-handle to the location that provides the best grip.

4. Tighten the wing nut until the D-Handle is secure.

Shaft Housing

Shield

Mount

Cutting

Attachment

Shield

Cutting

Attachment

Fig. 4

Recessed

Holes

Hex Lock

Nut

Screws (3)

Nuts (3)

Fig. 5

Fig. 6

WARNING:

O

VERFILLING OIL CRANKCASE MAY

CAUSE SERIOUS PERSONAL INJURY. Check and maintain

the proper oil level in the crank case; it is important and

cannot be overemphasized. Check the oil before each use

and change it as needed. See Changing the Oil.

RECOMMENDED OIL TYPE

Using the proper type and weight of oil in the crankcase is

extremely important. Check the oil before each use and change

the oil regularly. Failure to use the correct oil, or using dirty oil, can cause

premature engine wear and failure. Use a high-quality SAE 30 weight oil of

API (American Petroleum Institute) service class SF, SG, SH.

ADDING OIL TO CRANKCASE: INITIAL USE

NOTE: This unit is shipped without oil. In order to avoid damage

to the unit, put oil in the crankcase before you attempt to

start the unit.

Your unit is supplied with one 3.04 fluid oz. (90 ml) bottle of SAE 30 SF,

SG, SH oil (Fig. 7).

NOTE: Save the bottle of oil. It can be used to measure the correct

amount during future oil changes. See Changing the Oil.

1. Unscrew the top of

the bottle of oil and

remove the paper

seal covering the

opening. Replace the

top. Next, cut the tip

off the funnel spout

(Fig. 7).

2. Place the unit on a flat level surface (Fig. 8).

3. Remove the oil plug

/ dipstick from the

crankcase (Fig. 9).

4. Pour the entire

bottle of oil into the

oil fill hole (Fig. 9).

NOTE: Never add oil to

the fuel or fuel

tank.

5. Wipe up any oil that

may have spilled

and reinstall the oil

fill plug / dipstick.

Check oil before each

use and change as

needed. Refer to

Changing the Oil.

RECOMMENDED FUEL TYPE

Old fuel is the primary reason for improper unit performance. Be

sure to use fresh, clean, unleaded gasoline.

NOTE: This is a four cycle engine. In order to avoid damage to the

unit, do not mix oil with gasoline.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as

ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs water.

As little as 1% water in the fuel can make fuel and oil separate or form

acids when stored. Use fresh fuel (less than 60 days old), when using

alcohol-blended fuel.

Fig. 7

Funnel

Spout

Fig. 8

Oil Fill

Fig. 9

Oil Fill

Plug/Dipstick

O-Ring

Oil Fill Hole