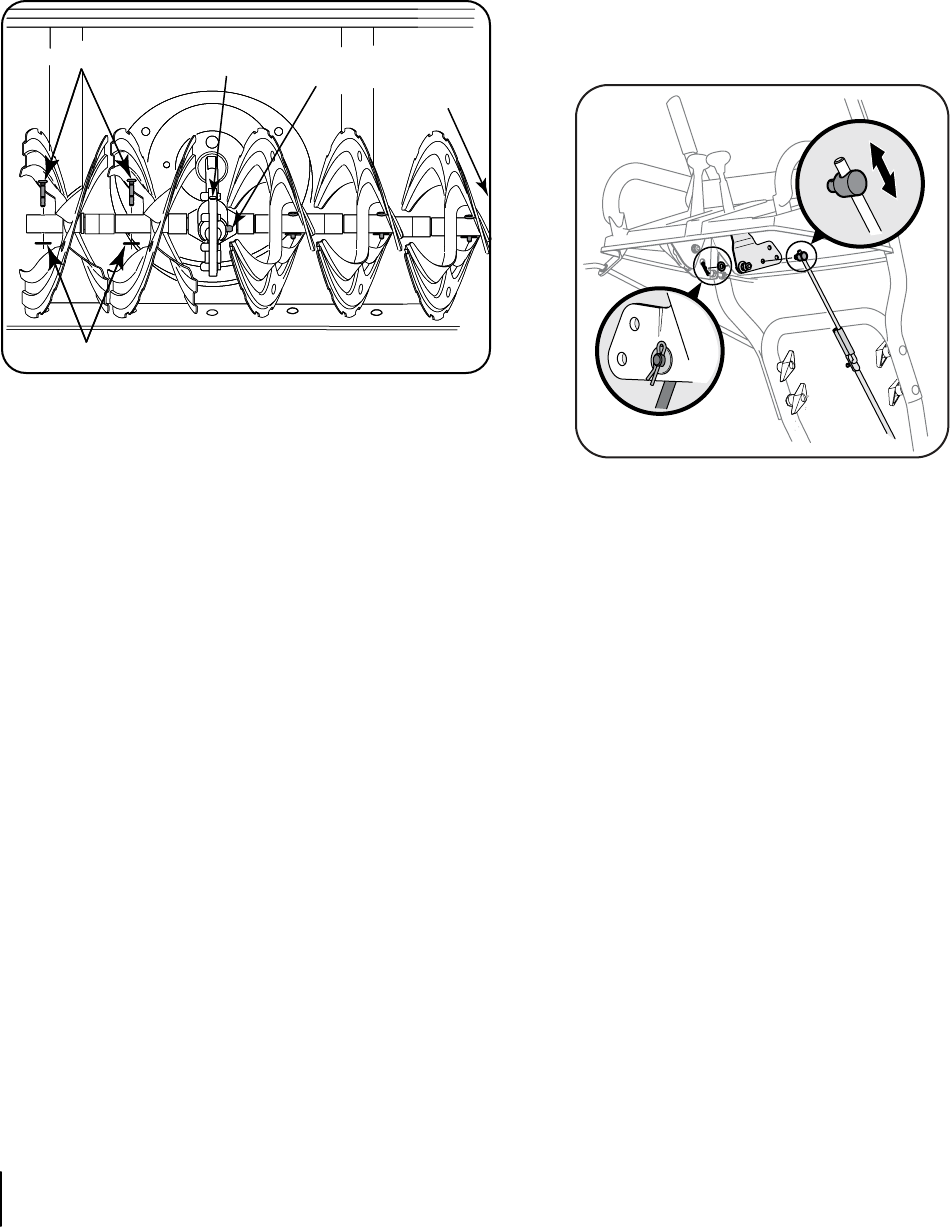

Auger Shaft

At least once a season, one at a time, remove the shear

pins from the auger shaft. Spray lubricant inside the hub

of each auger spiral assembly and around the spacers on

the auger shaft.

Grease fittings can also be found at each end of the auger

shaft. Lubricate flange bearings found at each end of the

shaft with a grease gun once a season. See Figure 6-3.

Gear Case

The auger gear case is equipped with a grease fitting.

Lubricate with Shell Alvania lead-free grease once a season

(order part number 737-0168). See Figure 6-3.

NOTE: To relieve pressure, remove the vent plug before

lubricating the gear case. See Figure 6-3. Failure to do so

could result in damage to the gear case seals.

Augers

Each of the six auger spiral assemblies is secured to the

spiral shaft with a shear pin and cotter pin. If the auger

should strike a foreign object or ice jam, the snow thrower

is designed so that the pins may shear.

If augers do not turn, check to see if pins have

sheared.

Replace the pins if needed. Two replacement shear

pins and cotter pins have been provided with the

snow thrower. Spray an oil lubricant into shaft before

inserting new pins and securing with new cotter pins.

1.

2.

Adjustments

Shift Rod

If the full range of speeds (forward and reverse) cannot be

achieved, refer to the figure to Figure 6-4 and adjust the

shift rod as follows:

1. Looking underneath the handle panel, note which of

the three holes in the shift lever the ferrule is inserted

into. Also note the direction of insertion. Then remove

the internal cotter pin and flat washer from the ferrule

and withdraw the ferrule from the shift lever. See Figure

6-4.

2. Place shift lever in sixth (6) position or fastest forward

speed.

3. Push shift rod and shift arm assembly down sharply as

far as it will go to shift the drive into the fastest forward

position.

4. As necessary, rotate the ferrule up or down the shift rod

until the ferrule lines up with the hole from which it was

earlier removed. See Figure 6-4.

5. From the direction noted earlier, insert the ferrule into

the proper hole. Reinstall the washer and secure with the

internal cotter pin.

Chute Bracket Adjustment

If the spiral at the bottom of the chute directional control

is not fully engaging with the chute assembly, the chute

bracket can be adjusted. To do so:

Loosen the two nuts which secure the chute bracket

and reposition it slightly. Refer to Figure 6-5.

Retighten the nuts.

1.

2.

Figure 6-4

Figure 6-3

Cotter Pin

Shear Pin

Cotter Pin

Vent Plug

Gearbox

Lube Fitting

at Each End

Lube Fitting

of Auger Shaft

16 sectiOn 6— Maintenance & adjustMents