Tighten Bolts and Nuts

Check for loose or missing hardware

every ten (10) operating hours. Failure to

tighten or replace fasteners can cause

poor performance, equipment damage or

oil leakage. See your Parts Catalog for

complete fastener descriptions.

Most hardware on your tiller is visible.

Pay particular attention to hardware

shown in Figures 5-1, 5-2, 5-3 and 5-3A.

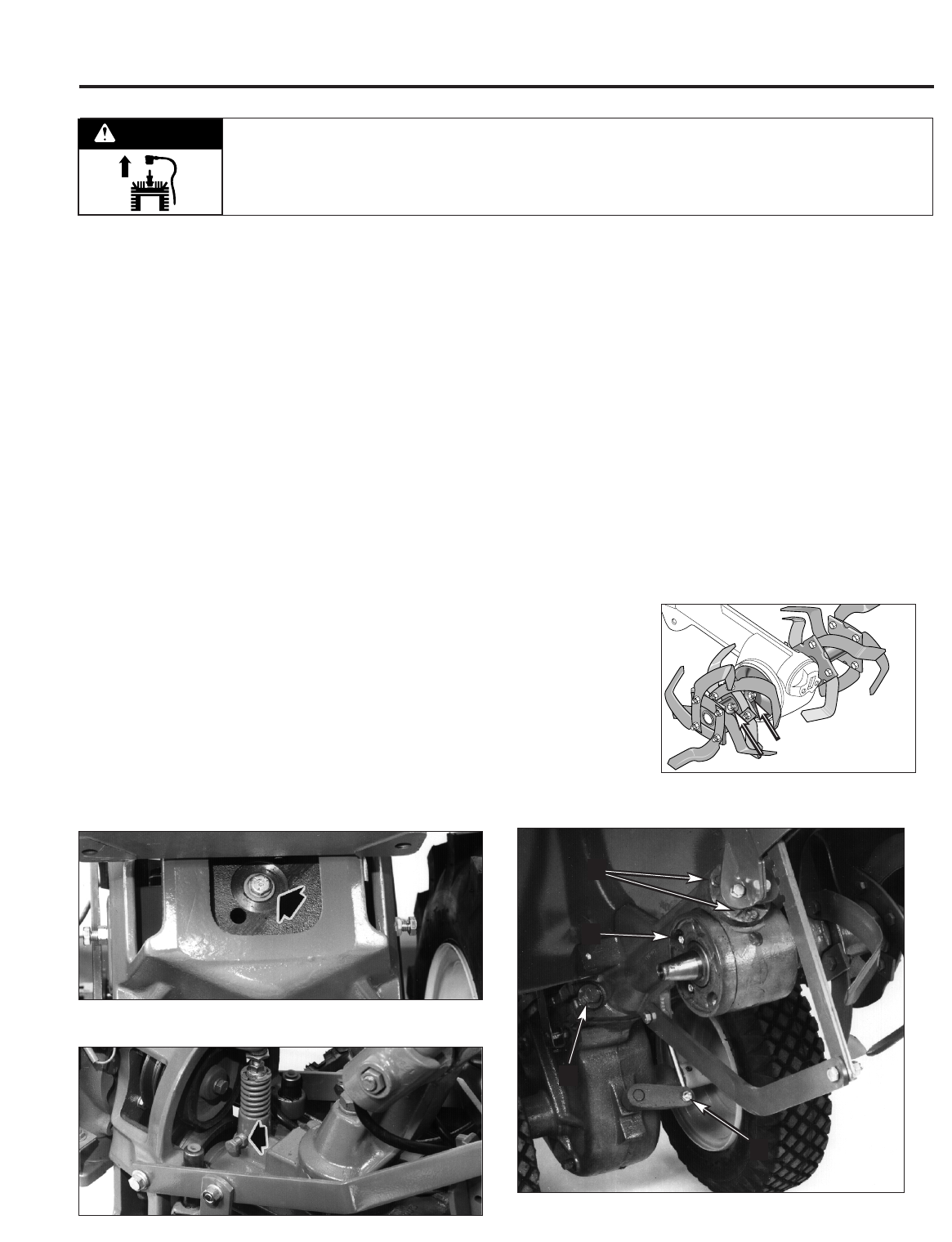

1. Check the transmission pulley

mounting bolt (Figure 5-1). If the washer

behind the bolt head is loose, the bolt

needs tightening. To do this, first insert a

punch or thick screwdriver into the hole

next to the bolt and wedge the tool

against the side of the motor mount

casting. This immobilizes the pulley while

you tighten the bolt.

2. Check jam nut on left side of neutral

plunger assembly (Figure 5-2). If loose,

immobilize bolt head with one wrench and

use another wrench to tighten the nut.

3. Check the three rear bearing cap

screws under the depth regulator

mounting bracket (A, Figure 5-3). If any

is loose, it can cause an oil leak or drive

shaft end play.

4. Check the five bolts securing the tiller

housing cover to the left side of the trans-

mission (B in Figure 5-3). Gear oil can

leak from a loose housing cover. To

reach the bolts, remove the left side tine

holder. See Bolo Tine Maintenance in this

Section for tine holder removal directions.

5. Check both swing-bolts (C, Figure 5-3)

that connect the power unit transmission

to the tine attachment. Both bolts should

be checked every 2-1/2 hours of

operation. If loose, wear can occur on the

locating pin on the power unit, and cause

enlargement of the locating hole in the

tine attachment. Using a torque wrench,

tighten these bolts to 70-to-80 ft.-lbs.

6. Check the locknut that fastens the

shifting linkage to the eccentric shifting

lever (D, Figure 5-3). Do not tighten the

locknut against the eccentric lever. It

should be very close to, but not touching

the lever.

7. Check the four bolts and nuts securing

left and right tine holders to the tine shaft

(Figure 5-3A).

IMPORTANT: Give screws or bolts that

go into the transmission housing a

coating of non-hardening gasket sealant

to prevent gear oil from leaking.

Tiller Lubrication

Proper lubrication of the tiller’s mechani-

cal parts is an essential part of good

maintenance. Lubrication should be done

after every ten (10) hours of operation.

Use ordinary motor oil (#30 weight or

lighter) where oil is specified. Use a

quality grease with a metal lubricant

where grease is recommended (regular

grease is acceptable). Do not over

lubricate. If there is a build-up of dirt,

remove the build-up and re-apply oil or

grease.

Figure 5-1: Check bolt on transmission pulley.

Figure 5-3A: Tine holder hardware

must be tight.

Figure 5-2: Check jam nut on plunger assembly.

Figure 5-3: Gently tilt tiller forward to check fasteners.

A

B

C

D

Section 5: Maintenance

29

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come

to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition

key, if so equipped.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING