Workman e2050/e2065 Page 5 – 11 Chassis (Rev. B)

Removal (Fig. 3)

1. Park vehicle on a level surface, turn on/off switch

OFF, set parking brake and remove key from the on/off

switch.

WARNING

Before jacking up the machine, review and follow

Jacking Instructions in Operator’s Manual and

Chapter 1 – Safety.

2. Chock wheels not being jacked up. Jack front wheel

off the ground and place blocks beneath the frame.

3. Loosen and remove five (5) lug nuts that secure

wheel to machine. Remove wheel from vehicle.

4. Remove wheel hub from spindle:

A. Carefully remove dust cap from the wheel to pre-

vent damage to the cap.

B. Remove cap screw and two (2) washers that se-

cure the wheel hub to the spindle. Slide wheel hub

from the spindle shaft.

5. If necessary, remove bearings from both sides of the

wheel hub (Fig. 4). Discard removed bearings. Retrieve

spacer from wheel hub. Clean the spacer and the inside

of the wheel hub.

Installation (Fig. 3)

1. If bearings were removed from wheel hub, position

spacer in wheel hub and press new bearings into the

hub until the bearing retaining rings seat against hub

(Fig. 4).

2. Install wheel hub to spindle:

A. Apply antiseize lubricant to spindle shaft.

B. Slide wheel hub onto spindle shaft with the wheel

studs facing out.

NOTE: Apply Loctite #242 (or equivalent) to the

threads of the cap screw.

C. Place large washer and then small washer onto

the cap screw. Thread cap screw with washers into

the spindle shaft.

D. Torque cap screw from 135 to 165 ft–lb (183 to

224 N–m).

3. Position wheel to studs in wheel hub and secure with

five (5) lug nuts. Torque lug nuts from 45 to 65 ft–lb (61

to 88 N–m).

4. Lower machine to ground. Remove chocks from

wheels.

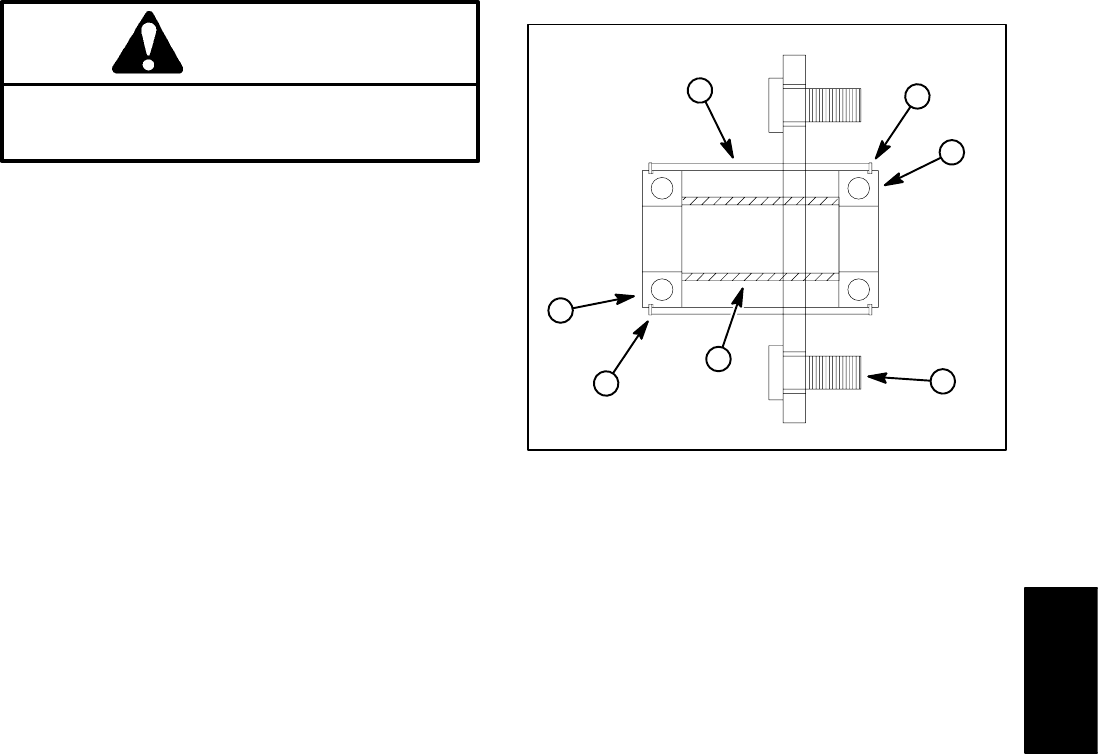

1. Wheel hub

2. Bearing

3. Retaining ring

4. Spacer

5. Wheel stud

Figure 4

2

3

1

2

3

4

5

Chassis