Workman e2050/e2065

Page 3 – 31

Electrical System (Rev. B)

Testing

When testing batteries in the Workman e2050 and

e2065, it is important to test all batteries. Proper perfor-

mance of the vehicle depends on all batteries being in

good condition. Testing will determine if one (or more) of

the batteries needs to be replaced.

1. The preferred testing procedure is to use the Lester

Electrical 36/48 Volt Battery Discharge Unit (Model

17770). This instrument puts a known discharge load

(56.25 Amps) on the battery pack until the battery pack

reaches 42 volts. A timer incorporated into the discharg-

er measures the time needed to reach that voltage level.

Battery capacity and remaining life can be determined

from the test results. Refer to Discharge Unit Operating

Instructions for further information.

Other types of battery load testers can also be used to

test the Workman batteries. Many locally available bat-

tery load testers do not, however, have any adjustment

on the load that is put on the battery. Results received

from using load testers should follow the recommenda-

tions of the load tester manufacturer.

2. If the Lester Battery Discharge Unit (or other load

tester) is not available, an alternate battery test can be

done using a multimeter to perform a voltage test of

each battery. Use the following procedure:

A. For accurate voltage testing, allow batteries to re-

main idle (no charging, no discharging) for at least 6

hours and preferably 24 hours.

B. Open the battery circuit by carefully removing

one of the battery cables (see Opening Battery Cir-

cuit in the General Information section of this chap-

ter). Then, disconnect both cables from battery to be

tested.

C. Measure the battery voltage with the multimeter.

Record battery voltage. The measured voltage will

determine battery state of charge.

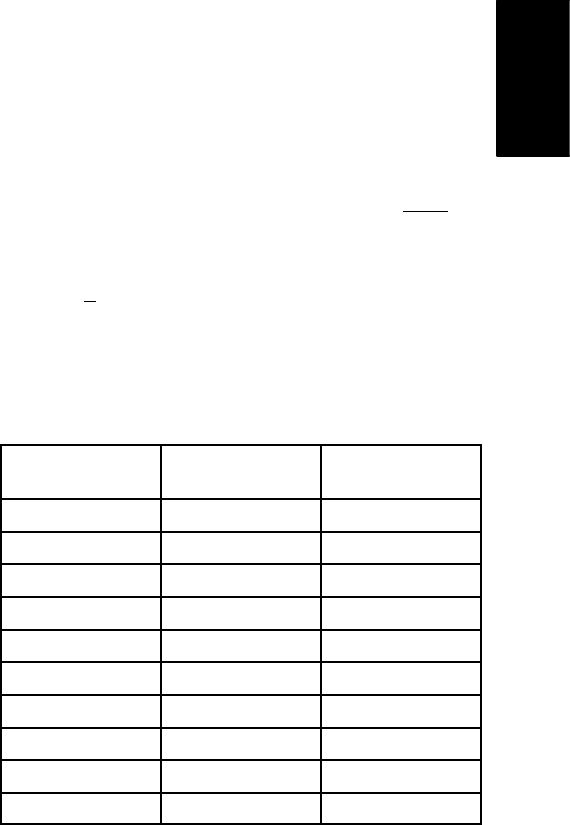

D. If voltage readings below 70% charged (see Fig.

47) exist, charge battery (see Operator’s Manual)

and take voltage measurements again. If voltage re-

mains low after charging, consider battery replace-

ment.

3. A third option for battery testing is to perform a specif-

ic gravity test of the battery electrolyte using a hydrome-

ter. Use the following procedure:

IMPORTANT: Make sure the area around the battery

fill caps is clean before removing the caps.

A. Remove battery filler caps. Do not add water prior

to testing specific gravity of battery electrolyte. If

electrolyte level is low, add distilled water and

charge battery (see Operator’s Manual) before per-

forming specific gravity test.

B. Measure the specific gravity of each cell with a

hydrometer. Fill and drain the hydrometer two to four

times before drawing a sample. At the same time,

take the temperature of the cell.

C. Have enough electrolyte in the hydrometer to

completely support the hydrometer float. Record the

hydrometer reading and return the electrolyte to the

battery cell.

D. Repeat test for remaining battery cells.

E. Temperature correct each cell reading. For each

10

o

F (5.5

o

C) above 80

o

F (26.7

o

C) add 0.004 to the

specific gravity reading. For each 10

o

F (5.5

o

C) below

80

o

F (26.7

o

C) subtract 0.004 from the specific grav-

ity reading.

Example: Cell Temperature 100

o

F

Cell Specific Gravity Reading 1.245

ADD (20

o

above 80

o

F) 0.008

Correction to 80

o

F 1.253

F. The specific gravity of all battery cells should be

1.277 +

.007. If low cell readings exist (see Fig. 47),

charge battery (see Operator’s Manual) and take

specific gravity readings again.

G. If specific gravity of any cells remain low after

complete charging, battery should be replaced.

Battery Charge

Level

Specific

Gravity

Open Circuit

Voltage

100% 1.277 6.37

90% 1.258 6.31

80% 1.238 6.25

70% 1.217 6.19

60% 1.195 6.12

50% 1.172 6.05

40% 1.148 5.98

30% 1.124 5.91

20% 1.098 5.83

10% 1.073 5.75

Figure 47

Electrical

System