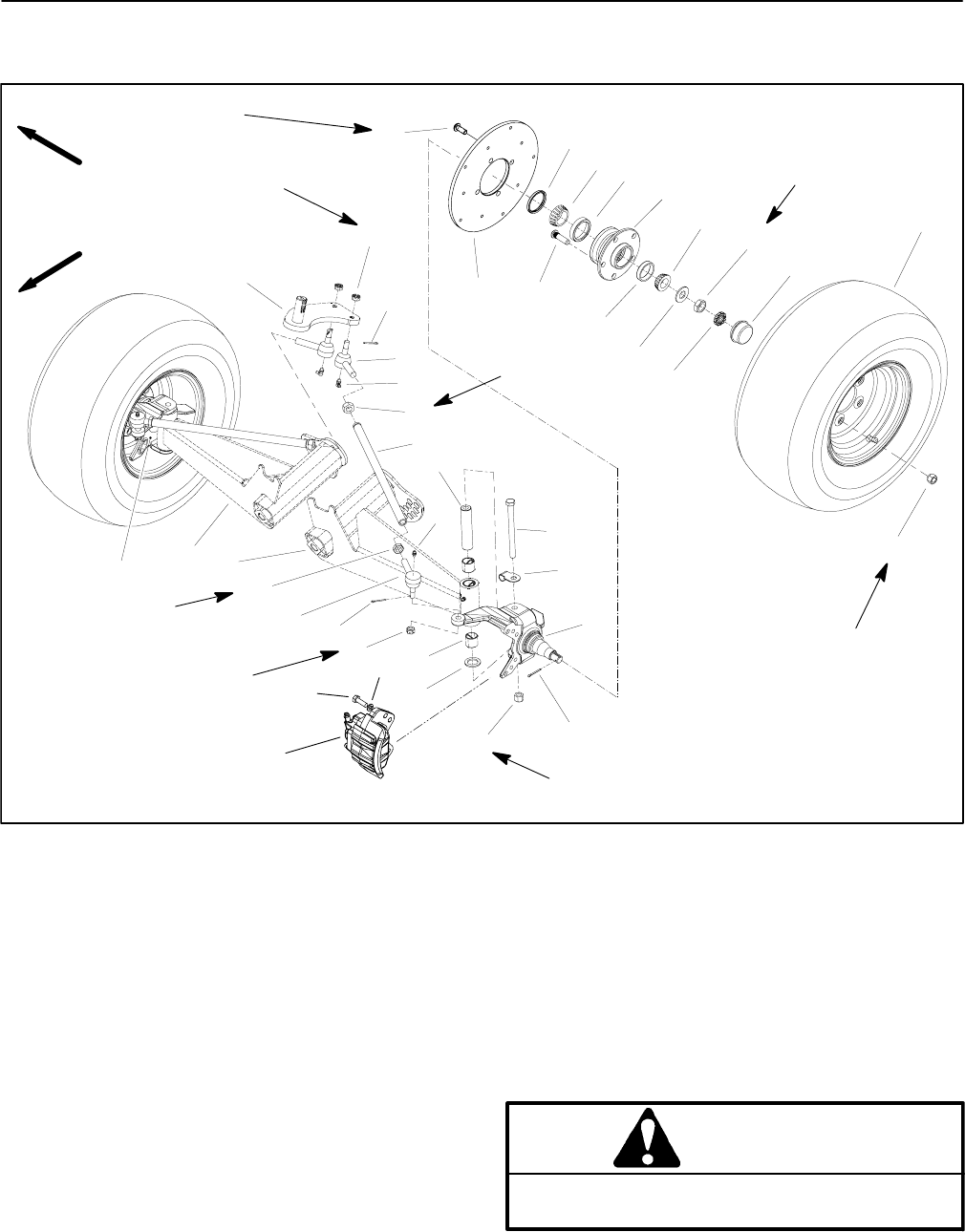

Workman e2050/e2065Page 5 – 14Chassis (Rev. B)

Front Wheels and Lower Steering (Workman e2065)

1. Wheel assembly

2. Lug nut (5 used per wheel)

3. Dust cap

4. Cotter pin

5. Nut retainer

6. Jam nut

7. Tab washer

8. Bearing cone

9. Bearing cup

10. Wheel hub

11. Wheel stud (5 used per hub)

12. Bearing cup

13. Bearing cone

14. Seal

15. Brake rotor

16. Socket head screw (4 used per rotor)

17. Lock nut

18. LH spindle

19. Cap screw

20. Brake hose bracket

21. Bushing (2 used per A–arm)

22. Thrust washer

23. RH spindle

24. Castle nut

25. Cotter pin

26. Kingpin sleeve

27. Ball joint (RH thread)

28. Jam nut (RH thread)

29. Tie rod tube

30. Pitman arm

31. Ball joint (LH thread)

32. Grease fitting

33. Jam nut (LH thread)

34. A–arm (RH)

35. A–arm (LH)

36. Grease fitting

37. Brake caliper (LH shown)

38. Lock washer (2 used per caliper)

39. Cap screw (2 used per caliper)

Figure 6

20 to 25 ft–lb

(27 to 34 N–m)

75 to 100 ft–lb

(102 to 136 N–m)

20 to 25 ft–lb

(27 to 34 N–m)

45 to 65 ft–lb

(61 to 88 N–m)

FRONT

RIGHT

Loctite #242

18

22

23

24

21

30

27

26

29

28

33

34

19

20

31

16

24

35

36

25

37

38

39

4

15

17

32

25

13

14

10

8

7

5

1

3

2

6

9

12

11

45 to 55 ft–lb

(61 to 74 N–m)

45 to 55 ft–lb

(61 to 74 N–m)

See text for

tightening

procedure

NOTE: Both tie rod assemblies consist of the following

parts: ball joints (27 and 31), jam nuts (28 and 33), tie rod

tube (29) and grease fittings (32 and 36).

Removal (Fig. 6)

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition.

WARNING

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 – Safety.

2. Chock wheels not being jacked up. Jack front wheel

off the ground and place blocks beneath the frame.