18

Troubleshooting

Troubleshooting, Adjustments, & Service

TROUBLESHOOTING

Troubleshooting procedures are provided in the

following chart. To use these procedures, first locate

the problem description that best describes the

trouble that you have encountered. Check the

possible causes one at a time in the order that they

are listed. Correct any problems that are found and

try to operate the rotary tiller again to see if you have

eliminated the trouble.

WARNING

For your safety, do not try to adjust or repair

the tractor or rotary tiller while the engine is

running. Always remove the key from the

ignition switch before beginning maintenance

to prevent accidental starting.

Symptom Problem Solution

Rotary tiller tines do not rotate. 1. Drive belt or pulleys oily.

2. Tiller drive belt too loose.

3. Rock jammed in tiller.

4. Tiller drive belt broken.

1 Clean as required.

2 Replace belt.

3. Remove it.

4. Replace as needed.

Tills too shallow 1. Tiller depth set too low.

2. Engine RPM speed too low.

3. Tractor ground speed too fast.

4. Ground too hard.

1. Adjust the attachment lift.

2. Set engine to full speed.

3. Slow down.

4. Make several passes, tilling

deeper on each pass.

Tiller leaves ground rough

with large clods.

1. Ground too wet.

2. Tilling too deep in one pass.

3. Tractor ground speed too fast.

1. Wait until sod does not ball up

when rolled in your hand.

2. Make several passes.

3. Slow down.

Tractor handles poorly. 1. Tractor ground speed too fast.

2. Front wheels lifting.

3. Rear wheels slip.

4. Tiller propels tractor.

1. Use slower speed, especially when

running on rough or sloping surfaces.

2. Clean dirt from tiller. Use front wheel

counterweights and weight carrier.

3. Use chains or wheel weights.

4. Tiller depth set too low.

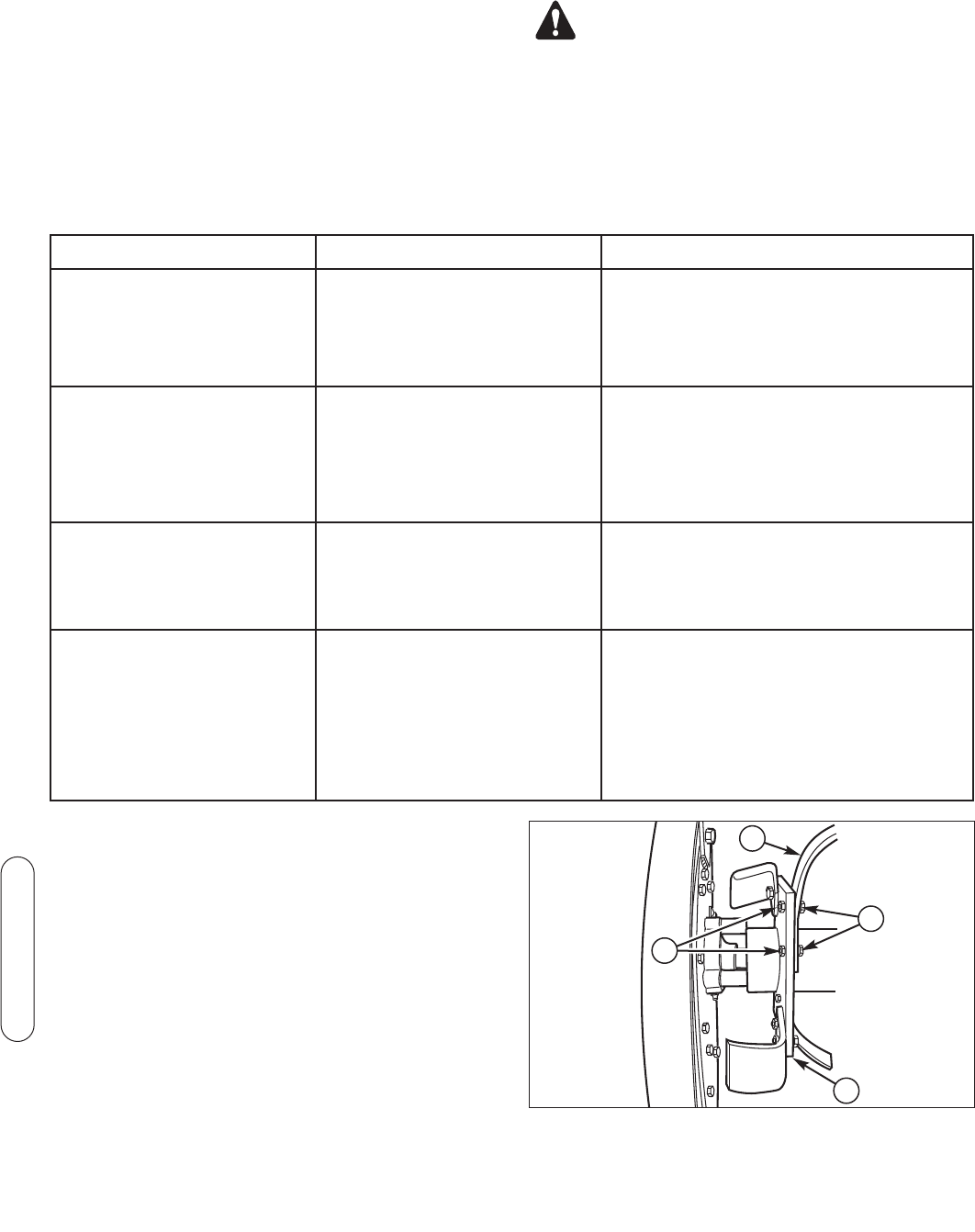

TINE REPLACEMENT

When required because of wear or breakage, replace

a tine as follows.

1. Remove two capscrews (A, Figure 21) and

locknuts (B).

2. Remove old tine (C) from tiller.

3. Place new tine on mounting plate (D). When

facing front of tiller, be sure tine curves away from

mounting plate with its sharp edge facing

rearward when tine nears bottom of travel.

4. Insert two capscrews (A) through tine and then

through mounting plate (D). Install and tighten

locknuts (B) to 30 lb-ft (40 Nm).

D

C

A

B

Figure 21. Tine Replacement

A. Capscrew

B. Locknut

C. Tine

D. Mounting Plate