PLUMBING FOR WATER CONNECTIONS

LOCATION

The VERSA heater requires water flow and positive

pressure to fire and operate properly. It must therefore be

installed downstream of the discharge side of the filter

pump. A typical installation is plumbed as follows:

1. The inlet side of the filter is plumbed directly to

the discharge side of the filter pump;

2. The outlet side of the filter is then plumbed to

the inlet of the heater; and

3. The outlet of the heater is plumbed to the

return line to the pool or spa. The pump, filter

and heater are thus plumbed in series.

Plumbing from the heater back to the pool must not have

any valves or restriction that could prevent flow when the

pump is operating. To do so will void the warranty.

FLOW RATES

MIN.GPM: 20, MAX.GPM: 115*

*When flow rates exceed 115 GPM an external auxiliary

bypass valve is required. See External auxiliary bypass

valve section for details.

CAST IRON HEADER

The inlet/outlet header accepts a 1-1/2" pipe thread.

The header will accept either copper and galvanized pipe

or CPVC adapters.

CAUTION: Never install PVC directly in header flanges.

The initial connection must be made with a higher

temperature material such as CPVC or Copper. PVC

may be utilized immediately after the initial connection.

13

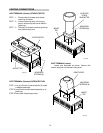

INLET/OUTLET HEADER

AUTOMATIC CHLORINATORS AND CHEMICAL

FEEDERS

All chemicals must be introduced and completely

diluted into the pool or spa water before being circulated

through the heater. Do not place chlorine tablets or

bromine sticks in the skimmer. High chemical concen-

trations will result when the pump is not running (i.e.

overnight).

Chlorinators must feed downstream of the heater and

have an anti-siphoning device to prevent chemical back-

up into the heater when the pump is shut off.

NOTE: High chemical concentration from feeders and

chlorinators that are out of adjustment will cause very

rapid corrosion to the heat exchanger in the heaters.

Such damage is not covered under the warranty.

1 1/2" NPT

INLET/ OUTLET

CONNECTIONS

IN/OUT

HEADER

Fig. # 9249

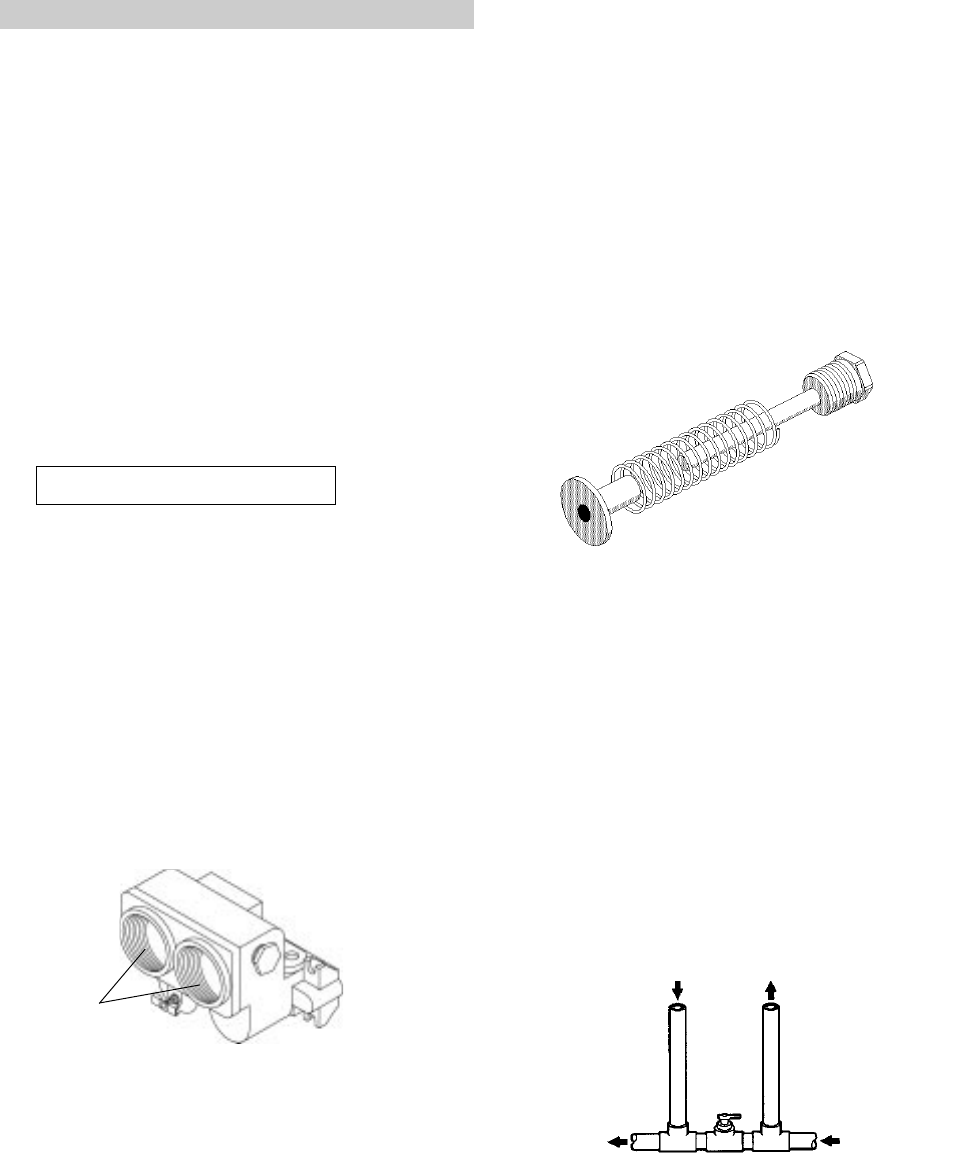

INTERNAL AUTOMATIC BY-PASS VALVE

A built-in automatic by-pass valve is provided in the

in/out header. The internal by-pass valve automatically

responds to changes in water pressure in the piping

system. Proper amount of water flow is maintained

through the heater under varying pressures dictated by

the conditions of the pump and filter.

Fig. # 8078.0

EXTERNAL AUXILIARY BYPASS VALVE

(Where required)

An auxiliary bypass valve should be used when flow

rates exceed 115 GPM (usually a high performance

pump size larger than 2 HP will exceed this flow rate).

This valve is required to complement the function of the

automatic bypass valve, particularly when starting the

heater in winter or early spring when the spa or pool

temperature is down below 55°F. It also serves to

eliminate needless pressure drop through the heater and

accompanying reduction in the flow rate to the spa jets,

etcetera.

From Heater To Heater

To Pool From Pool

Auxiliary Bypass Valve (do not use gate valve)

Fig. # 8150.

AUXILIARY BYPASS VALVE ADJUSTMENT

To set bypass: With clean filter, adjustment is made

by feeling the inlet and outlet pipes at the heater. Outlet

pipes should be slightly warmer than inlet and comfort-

able to the touch. If pipe is hot, close bypass; if cold, open

bypass.