17

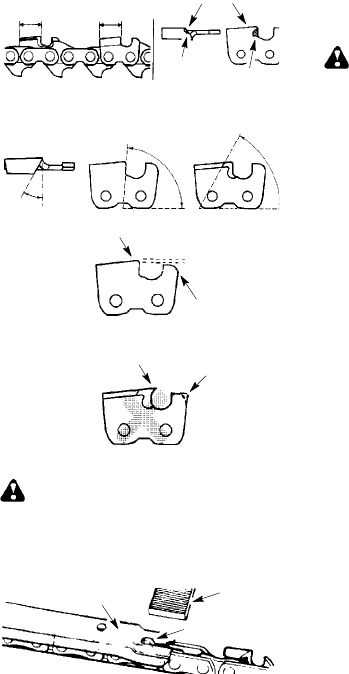

S Fileontheforwardstrokeonly.Use2

or 3 strokes per cutting edge.

S Keep all cutters the same length

when filing.

S File enough to remove any damage

to cutting edges (side plate and top

plate of cutter).

A

ll Cutters

Same Length

Remo

v

e Damage

Top Plate

Side Plate

S File chain to meet the specifications

as shown.

30˚

80˚

60˚

Rounded

Corner

0.025 inch

(0.65mm)

Right

Hook Angle

Wrong

Squared O

f

f

Corner

Too Much Hook

A

ngle

WARNING: Maintain the proper

hook angle according to the manufacturer’s

specifications for the chain you are using. Im-

proper hook angle will increase the chance of

kickback which can result in serious injury.

4. Check and lower depth gauges.

Depth Gauge Tool

Depth Gauge

File

S Place gauge t ool oncutter.

S If the depth gauge is higher than the

depthgaugetool,fileitleveltothetopof

the depth gauge tool.

S Maintain rounded front corner of

depth gauge with aflat file.

NOTE: The very top of the depth

gauge should be flat with the front

half rounded off with a f lat file.

If you require further assistance or are unsure

about performing t his procedure, contact your

authorized service dealer or call our customer

assistance help line at 1--800--554--6723.

CARBURETOR ADJUST MEN T

WARNING: Thechain willbemov-

ingduringmostofthisprocedure.Wearyour

protective equipm entand observe all safety

precautions.Thechainmustnotmoveatidle

speed.

The carburetor hasbeen carefully set at the

factory. Adjustments may be necessary if

you notice any of the following conditions:

S Chain moves at idle.SeeIDLE SPEED--T

adjusting procedure.

S Saw willnotidle.See IDLESPEED--T ad-

justing procedure.

Idle Speed--T

Allow engine to idle. If the chain moves, idle is

toofast. Ift heenginestalls,idleistooslow . Ad-

just speed until engine runs without chain

movement (idle too fast) or stalling (idle too

slow). The idle speed screw is located in the

area above the primer bulb and is labeled T.

S Turn idle screw (T) clockwise to increase

engine speed.

S Turn idle screw (T) counterclockwise to

decrease engine speed.

If you require further assistance or are unsure

about performing t his procedure, contact your

authorized service dealer or call our customer

assistance help line at 1--800--554--6723.

COOLING SYSTEM

To keep the working temperature as low as

possible the machine is equipped with a

cooling system.

The cooling system consists of:

S Air intake on thestarter

S Air guide plat e

S Fins onthe flywheel

S Cooling fins on the cylinder

S Cylinder cover (directs cold air over the

cylinder)

Clean the cooling system with a brush after

each use, more often in demanding condi-

tions. A dirty or blocked cooling system re-

sults in the machine overheating which

causes damage to the piston andcylinder.