SP7060 PAVEMENT SAW • OPERATION MANUAL — REV. #0 (02/13/09) — PAGE 23

CHOOSING PROPER BLADE SIZE

CHOOSING PROPER BLADE SIZE

Proper blade selection is a product of:

■

Understanding the capability of your saw

■

Understanding the specifications of the engine

■

Understanding the blade shaft speed of your saw

■

Understanding diamond blade operating limitations

■

The depth of cut required

■

Cutting conditions

■

Desired cutting performance requirements

Engine (RPM) and Surface Feet per Minute (SFPM)

Speeds

This saw uses a belt drive system to propel the diamond

blade. Specifically sized engine drive and blade shaft

pulleys, engine (RPM) and blade diameter determine the

ultimate peripheral speed (SFPM) of the diamond blade. It

is important to understand the SFPM speed — For safety

and performance, it is essential that the selected

diameter diamond blade be matched up to a proper

SFPM (see Table 8).

Five 7060 models are available (706016, 706020, 706026,

706030, 706036) and are designed with different pulley ratio

speeds to govern the blade shaft RPM output. The

combination of the different diameters of the pulleys along

with engine (RPM) determines this ratio that ultimately

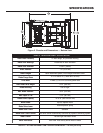

provides a RPM speed at the blade shaft (Figure 7).

Figure 7. Blade Shaft Ratios

Ratio Speeds and Blade Guard Size

The 7060 Series offer five blade guard sizes (16", 20", 26",

30", 36") that will accommodate most commonly used

diamond blades up to a 36" (914 mm). The series further

offers four distinct pulley ratio set-ups that provide specific

blade shaft RPM. Pairing a diamond blade diameter to a

proper ratio speed and blade guard size is imperative.

Additionally, matching up blade diameters with the

appropriate blade guard size is equally as important. See

Table 7.

trahCgniziSdrauGedalB.7elbaT

drauGedalB"61"02"62"03"63

edalBdnomaiD

).ni(retemaiD

"41"61"42"42"62

"61"81"62"62"03

"02"03"6

3