38

Section 4 Maintenance and Lubrication

Z52®, Z60® & Z72® Zero Turning Radius Mowers Accu-Z 356-005M 03/11/03

Land Pride

Belt Replacement

Refer to Figure 4-10 and Figure 4-11:

Replace belts which show signs of severe cuts, tears,

excessive weather checking and cracking or burns

caused by slipping. Slight raveling of belt covering does

not indicate failure, trim ravelings with a sharp knife.

Inspect the belt pulley grooves and flanges for wear. A

new belt, or one in good condition, should never run

against the bottomof thegroove. Replacethe pulley when

this is the case, otherwise belt will lose power and slip

excessively.

Never pry a belt to get it on a pulley as this will cut or

damage the fibers of the belt covering.

Keep oil and grease away from belts, and never use belt

dressings. Any ofthese will destroy thebelt composition in

a very short time.

Mower Blade Maintenance

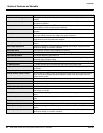

Lift Jack Option

For easier blade maintenance a liftjack can be purchased

from your LandPride Dealerand easilyassembled toyour

mower. Refer to Figure 4-12.

Check the mower blades daily, they are the key to power

efficiency and well groomed turf. Keep them sharp, a dull

blade will tear rather than cut the grass, leaving a brown

ragged top on the grass within a few hours. A dull blade

also requires more power from the engine.

Replace any blade which is bent, cracked or broken.

Never attempt to straighten a bent blade by heating, or

weld a cracked or broken blade as the blade may break

and cause serious injury.

!

DANGER!

Never work with blades while engine is running or deck clutch

is engaged. Always place deck clutch in the disengaged

position, place control levers in park position and turn engine

off. Block up mower when you must work under it. Do not use

jack as blocks. Jack is for lifting only. Separate blocks must be

used prior to servicing under mower. Wear gloves when

handling blades. Always check for blade damage if mower

strikes rock, branch or other foreign object during mowing!

Mower Blade Removal

Use a 3/4" wrench to remove the 1/2" cap screw holding

blade to spindle saddle from underneath.

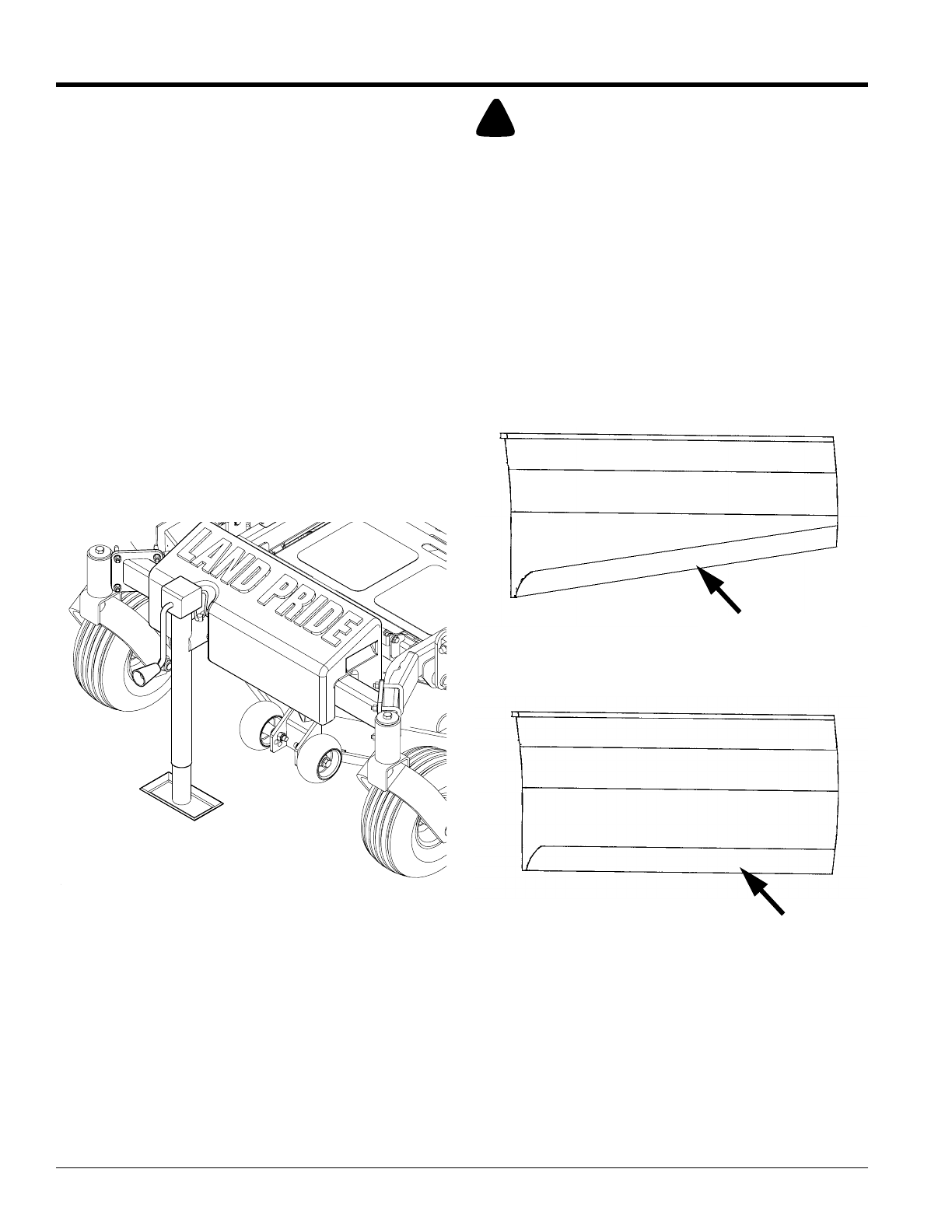

Sharpen the blades on a grinder following pattern as

shown in Figure 4-13. Touch-up sharpening can be done

with a file.

Check the blades for balance following grinding. A

commercial balancing tool is available through most

hardware supply stores, or balancing can be done by

placing the blade on an inverted line punch or 1/2" bolt.

Blade should not lean or tilt. Spin the blade slowly, blade

should not wobble. If blade is out of balance, true it up

before reinstalling.

Lay the blade on a flat surface and check for distortion.

Replace any distorted blade. Refer Figure 4-14 and Figure

4-15 on next page.

Lift Jack

Figure 4-12

19912

Resharpening Pattern

Do not sharpen to original pattern (below).

It is easier to get a straight cutting edge following the

resharpening pattern shown above.

Original Edge

Blade Resharpening

Figure 4-13

19074

19075