22

Section 3 Adjustments

Z52®, Z60® & Z72® Zero Turning Radius Mowers Accu-Z 356-005M 03/11/03

Land Pride

Control Lever Stops

The control lever stops (Figure 3-3)are designed to do two

things: First, and most important, they must keep the

pumps from bottoming out internally. Second, the stops

may be adjusted to help drive straight when the control

levers are pushed forward against the stops.

To keep the pumps from bottoming out internally use the

following procedure:

1. To make the first adjustment the mower engine must

NOT be running.

2. Check to make sure the control levers are against the

stops before the pumps are bottomed out internally. To

do this, gently and slowly move the control levers

forward and feel if there is some resistance on the

pump lever before the control levers hit the stops.

Check one side at a time. If you sense that the pump

arms are stopping the forward motion of the control

arms, loosen the jam nut on the adjustable stop of the

corresponding side and turn the stop (set screw)

inward to stop the control levers slightly before the

pump bottoms out.Lock in placewhen theadjustment

is correct by re-tightening the jam nut.

3. Do this for each side.

To adjust the stops for driving straight when control levers

are against the stops during operation:

Determine which drive tire is rotating too fast when both

control levers are against the stops. Then stop the mower

and loosen the lock nut on the side which is rotating too

fast and turnthe stop (setscrew) inward tostop the control

lever sooner. Tighten the lock nut on the stop and test

again. Repeat this procedure until unit drives straight.

Reverse Spring Adjustment

Refer to Figure 3-4:

The reverse spring is designed to bring the control levers

to the neutral position after they are released from the

reverse position.

To adjust:

1. Make certain the control lever neutral adjustment is

correct. If not, refer to Steering Linkage section.

2. When control lever is in the reverse position thespring

should force the control lever to return to neutral after

the lever is released.

3. Adjustthe topnylock nut on the springlinkage untilthe

control lever returns to the neutral position from the

reverse position properly. Tightening the nylock nut

will cause the control lever to travel forward less

before stopping. Loosening the nylock nut will allow

the control lever to travel farther forward.

4. Check the length of the reverse spring when the

control lever is in the neutral position. This dimension

should be 1 7/8”. If it is not, adjust the lower nylock nut

until the dimension is achieved.

5. Repeat for other side.

19081

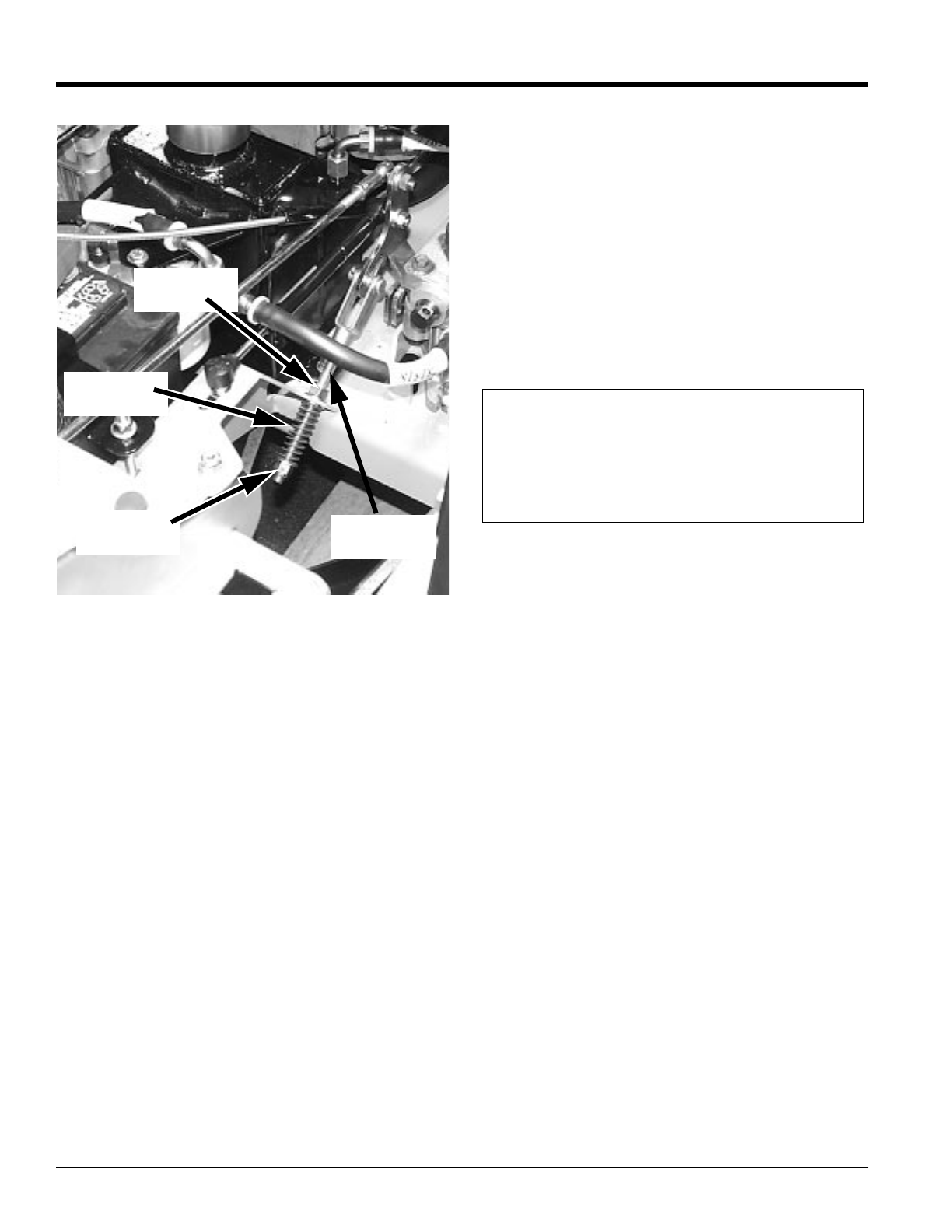

Reverse Spring

Figure 3-4

Top Nylock

Nut

Reverse

Spring

Lower

Nylock Nut

Spring

Linkage

NOTE: Since this is a hydrostatic drive, variables

such as temperature of oil, efficiency of pumps and

motors, tire pressure etc., may effect the consistency

of the ability to rely on the stops to drive straight

without the operator making minor steering

adjustments with the control arms.