33

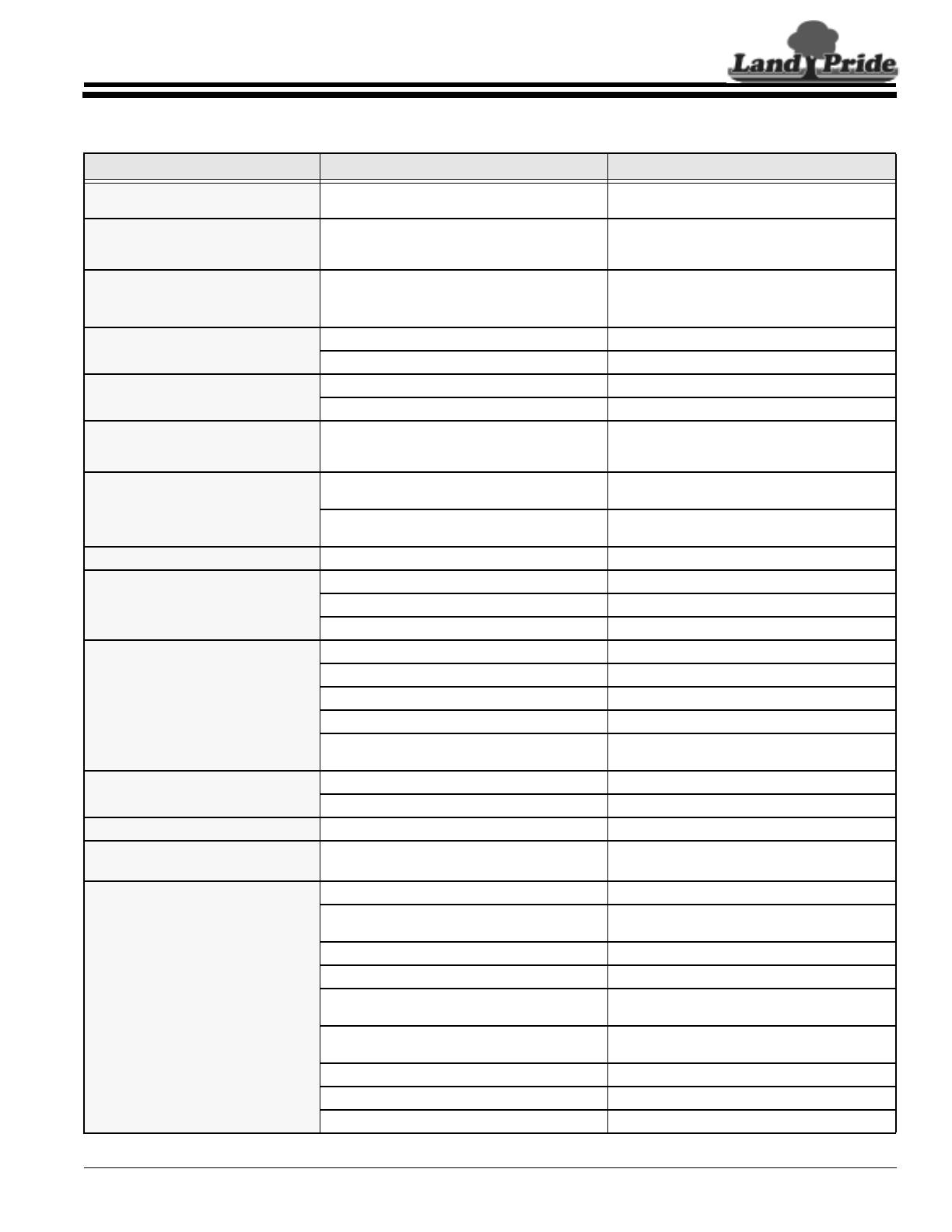

Section 9: Troubleshooting

4/28/08

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

Land Pride

Table of Contents

Section 9: Troubleshooting

Problem Cause Solution

Motor Oil Seal Leaking Return line from motor has been pinched or

is collapsed

Replace lower seal of motor. Check motor

return hose for kinks.

Spindle Hub Seal Leaking Return line from motor has been pinched or

is collapsed

Replace lower seal of motor and Spindle

Hub output shaft seal. Check motor return

hose for kinks.

PTO Shaft is bent. (NOTE: PTO

tractor hitch shaft should be

repaired or replaced if bent)

Contacting drawbar or Bottoming out Reposition drawbar/Replace PTO tubes

and cut to correct length.

Blades wearing excessively Cutting on sandy ground Raise cutting height.

Contacting ground frequently Raise cutting height.

Blades coming loose Insufficient shimming Add shimming. See text.

Blade bolts not tightened properly Torque blade bolt nuts to 450 ft lbs.

Blades breaking Hitting solid objects Thoroughly check the cutting area

BEFORE beginning to cut. Be alert during

cutting.

Loose Blade Carrier Worn Spindle Hub bearings. Replace Spindle Hub bearings and/or

shaft.

Shaft nut loose Tighten Spindle Hub shaft nut to

450 ft lbs. minimum.

Blade Carrier bent Hitting solid objects Avoid solid objects/Be alert.

Excessive skid shoe wear Cutting height not level or blade missing Adjust deck height or replace

Soil abrasive Raisecuttingheight.

Cutting too low Raise cutting height.

Excessive vibration Locked blades Inspect and unlock blades.

Blades have unequal weight Replace blades as a PAIR.

PTO shaft bent Straighten or replace PTO shaft.

Blade carrier bent Replace/straightenbladecarrier.

PTO cross not centered with yoke Disassemble and inspect for incorrectly

located needles or damaged bearing cap.

Deck Cylinder will

not extend and/or retract

Orifice elbow on rod end is plugged Clean orifice fitting.

Broken/disconnected wire on solenoid Check wiring on cartridge valve solenoids.

Deck Cylinder will not retract Cylinder rod is bent Replace cylinder.

Arm/Deck Cylinder(s) will not

extend and/or retract

Electric solenoid valve is sticking/dirty. Remove solenoid valve and clean or

replace.

Optional Electrical control

switch does not work

Circuit Breaker tripped Reset Breaker

Circular Plastic connector is not connected

to receptacle.

Connect remote cable to Solenoid Control

valve.

No power to switchbox connections. Check battery or power

Tractor spool valve not engaged (open). Lock tractor control valve open.

Flow Control Valve not adjusted properly

for open/closed center tractor

Adjust flow control valve

Hoses not connected to proper duplex

outlet on tractor

Connect hoses to proper tractor outlet.

Defective solenoid on cartridge valve assy. Replace solenoid.

Solenoid Valves sticking. Remove/clean/replace solenoid valve.

Tractor hydraulic fluid level is too low. Add fluid to tractor reservoir.