16

Section 2: Assembly & Set-up

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

4/28/08

Land Pride

Table of Contents

Check the hydraulic fluid level in your tractor's

reservoir. If low, add fluid to the system before

proceeding. The cylinders and hoses will require

approximately 1 3/4 gallons from the tractor.

d. Move the tractor and cutter to a remote location

(away from all other persons) to check pump/

motor operation. Check to be sure the Hydraulic

Reservoir shut-off valve is full OPEN. If this

service valve is turned off, damage will occur to

the pump.

Position the cutter deck flat on the ground or

concrete surface. SLOWLY engage the PTO to

start blade rotation. On initial start-up, blade

position may cause the deck to “vibrate”. After 2-

3 revolutions, these vibrations should stop. If the

deck continues to vibrate, shut off the PTO, raise

the deck and check for locked blades.

Gradually increase engine RPM until PTO output

RPM is 540. The deck should not exhibit

excessive vibration.

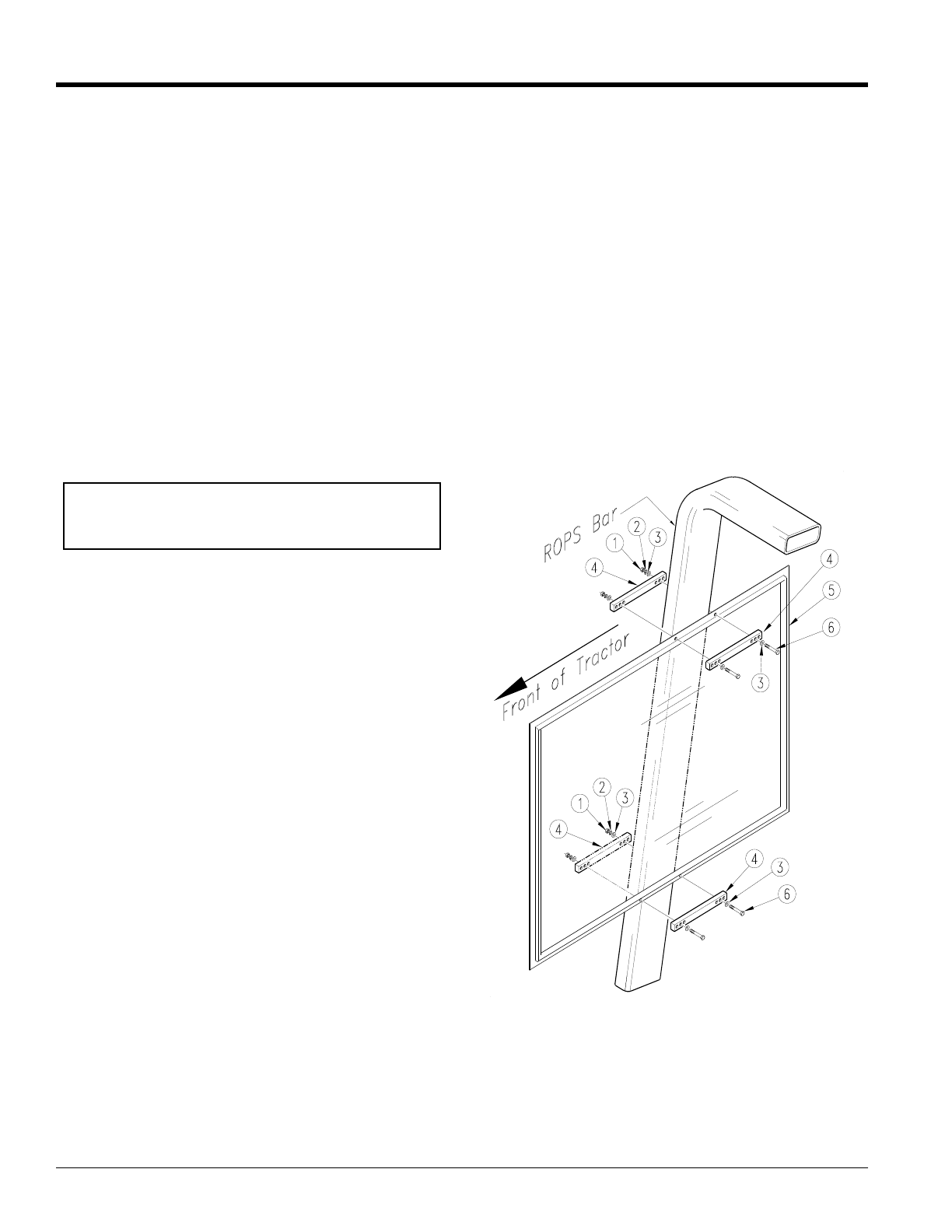

Operator Protective Shield

An optional operator protective shield is available for use

on tractors not equipped with cabs or other protective

shielding. This shield is a "universal" type and is suitable

for attachment to a conventional Roll Over Protective

Structure (ROPS) bar that is already attached to the

tractor. The shield is constructed of an extruded

aluminum frame and is glazed with 1/4" clear, lexan

polycarbonate.

Mounting hardware will permit attachment to ROPS

having cross-section dimensions of 2" x 4", 2" x 5", and

2" x 6" or 2 1/2" x 4", 2 1/2" x 5 and 2 1/2" x 6. Other sizes

may require longer mounting bolts and/or custom

flatbars. Installation requires that 4 mounting holes be

drilled in the frame of the shield. No modification is made

to the ROPS.

Installation

Refer to Figure 2-11:

Measure the width and thickness of the ROPS bar on the

tractor to determine that the clamping hardware supplied

will be adequate.

Compare the parts list on and quantities with the parts

received. Report any missing or damaged items to your

dealer.

To determine the best location for the shield, the cutter

should be connected to the tractor. The parallel arms

should be fully extended and the deck should be

horizontal (or approximately level).

IMPORTANT: If the tractor being used is equipped

with a 1000 RPM PTO output, be sure that throttle

RPM is reduced to limit PTO output to 540 RPM.

Carefully remove the shield from the shipping carton and

temporarily position it on the inside surface of the ROPS

bar. Locate the shield forward/back, up/down to provide

the best overall coverage for the tractor operator. Use a

spirit level to level the shield before marking. Mark the

top frame location with a pencil on each side of the

ROPS bar, and mark the vertical ROPS location on the

frame of the shield.

Position the shield (#5) on a flat work surface. Locate

one of the 316-116D (#4) flatbars next to the pencil

marks to determine which set of holes will clear the

vertical marks for the ROPS location. Mark the hole

location and drill two 1/4" diameter holes through the

frame of the shield. Similarly mark and drill two additional

holes for the lower clamp location.

Attach the shield to the inside surface of the ROPS bar

using the mounting hardware provided (#1), (#2), (#3),

and (#6).

Operator Protective Shield

Figure 2-11

13239