17

Section 4 Maintenance and Lubrication

7/18/08

DM35 Series (S/N253045+) Disc Mowers 309-502M

Land Pride

Table of Contents

General Maintenance

Proper servicing and adjustment is the key to the long life

of any farm implement. With careful and systematic

inspection, you can avoid costly maintenance, time and

repair.

!

DANGER

Before servicing this machine, turn off the tractor engine,

remove the ignition key and disconnect the PTO driveline.

Each new machine should be checked after the first 10

hours of work. All screws and bolt torques should be

routinely checked.

At the beginning of each season:

1. Check and/or change the oil; lubricate or grease all

points. See Lubrication in this section.

2. Check blade wear and condition of their fasteners, see

“Servicing Blades”, page 17.

3. Check wear on guards and curtain.

4. Retention belts, see “Belt Tensioning Adjustment”,

page 15.

5. Check all screws and bolts to be sure they are tight.

Servicing Blades

Cutting quality as well as safe operation depend on the

regular inspection and care given to the knives.

!

WARNING

To avoid personal injury when the blades and/or carrier are

being serviced, always block the mower up to prevent it from

falling.

Check blades for cracks and wear and blade bolts for

tightness daily. Blades should be replaced when they are

worn excessively, bent, nicked, deformed, or out of

balance.

!

CAUTION

Replace with Land Pride blades only. Substitute blades may not

meet specifications and may fail in a hazardous manner that

could cause injury.

NOTE: Blade bolts should be tightened to 55 ft-lb

torque.

NOTE: Always replace damaged blades. Never

straighten a bent blade. Never replace one knife only

per disc. Always replace both of them to avoid

creating an out-of-balance force.

!

CAUTION

When changing blades, always replace the blade bolt & blade

nut together at the same time. Worn or damaged blade bolts or

nuts could fail in a hazardous manner that could cause injury.

Blade Replacement

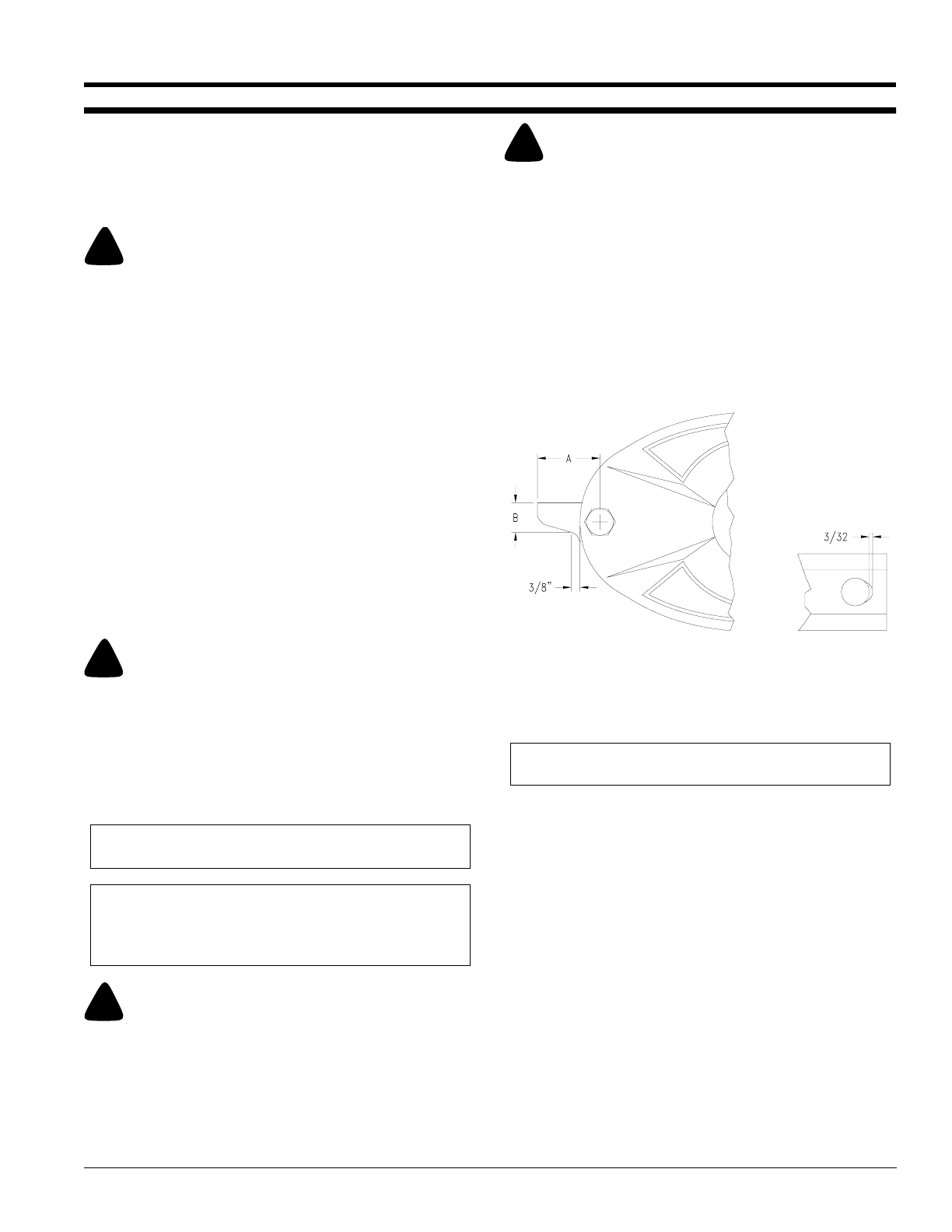

1. See Figure 5-1a. New blades are 1 3/4” wide. Blades

should be replaced when they are worn to about

1 5/16” (B) wide at a distance of 3/8” from the disk. The

length (A) of the blade should be greater than 2 1/2”.

2. See Figure 5-1b. Replace blades if the hole for the

securing bolt has become oval 3/32” more than the

diameter of the original hole.

Fastener Replacement

1. Replace fasteners when a visible deformation is

found.

2. See Figure 5-2a. Replace bolts when wear on the bolt

head reaches the contact area of the blade.

3. Replace bolts when the flat sides at the bolt flange are

excessively worn or missing altogether.

4. See Figure 5-2b. Replace bolts when the diameter (D)

of the bolt shoulder is less than 5/8”.

5. See Figure 5-2c. Replace nuts when the height (H) of

the nut less is than half of the original height of 5/16”.

6. Replace Belleville washers on breakaway if they are

flattened.

Blade Wear

Figure 5-1

15093

a

b

NOTE: Always replace blade bolts and nuts when

they have been removed 5 times.

Section 4 Maintenance and Lubrication