8

Section 1 Assembly and Set-Up

DM35 Series (S/N253045+) Disc Mowers 309-502M

7/18/08

Land Pride

Table of Contents

Tools Required

•

Fork lift, crane hoist or block-and-tackle

• Impact wrench or socket and ratchet set (metric)

• Rubber mallet

• Box-end (metric), allen (metric) and crescent wrenches

• Drift pins

• Screwdriver

• Safety shoes, safety glasses and gloves. A hard hat

should be worn by anyone working under the crane.

Assembly Preparation

Having all the parts and equipment readily at hand will

speed up your assembly task and make the job as safe as

possible.

Prepare the area where the unit is to be assembled mak-

ing sure the area is swept clean of all dust and contami-

nants. Un-package the crate and remove all contents

carefully so that the seals on hydraulic components are

not broken or pulled off.

Raise the mainframe with a forklift, hoist or block-and-

tackle and place on pallets or blocks so it is elevated about

10” off the floor.

Your cutter bar will already be assembled. It is necessary

to check the direction of rotation of each cutter plate.

Figure 1-1 shows the proper cutter bar plate rotation. If

adjustments need to be made, refer to “Cutter Bar

Timing Adjustment” on page 18.

It is also necessary to check whether the plate turning

right has right cutter blades and the plate turning left has

left cutter blades.

NOTE: Remove heavy components from crate with a

hoist or block-and-tackle.

Cutter Bar Plate Rotation

Figure 1-1

15144

Cutter Bar and Gearbox Lubrication

The cutter bar should arrive with oil already added. After

assembly you may want to check to make sure. For

instructions on how to do this see Lubrication in “Section

4 Maintenance and Lubrication” on page 17 and

“Section 5 Specifications and Capacities” on page 22.

Before operating this unit add SAE 80 GL4 (EP) oil to

gearbox. For further instructions see Lubrication in

“Section 4 Maintenance and Lubrication” on page 17

and “Section 5 Specifications and Capacities” on

page 22.

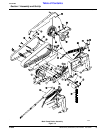

Refer to Figure 1-2:

1. Insert bushing (#1) into mainframe (#7) and slide over

gearbox as shown.

2. Insert the pivot plate (#43) that is already assembled

to the cutter unit (#2) onto the mainframe studs and

secure with bolts (#3) and washers (#4).

3. Insert the release arm (#8) between the lugs on the

mainframe and secure with pin (#12), washers (#13)

and cotter pins (#14). Install the bushing (#10) and the

chain(#9) on the hitch pin. Insert the other end of the

release arm (#8) on to the hitch pin as shown.

4. Assemble the tie rod (#41) to the mainframe lugs as

shown using the pin (#5) and roll pin (#6). The other

end is already assembled.

5. Place the pulley mount (#15) on the mainframe as

shown. Install belt (#23) on both pulleys. Insert the

belt tightening rod (#18) into the pulley mount (#15).

Slide the pulley mount on the mainframe until the belt

tightening rod (#18) can be inserted into the hole of

the mainframe lug and retain with nut (#19). Install

u-bolt (#16) and nuts (#17). Tighten the belt by

tightening the nut (#19) on the belt tightening rod

(#18). There should be a 3/4” deflection in the belt.

Refer to “Adjustments” page 15. Tighten the u-bolt

(#16). Assemble the driveline shield (#20) to the

gearbox mount with the bolts (#21) and washers

(#22).

6. Install the bottom and top belt guards (#24) and (#25)

to the mainframe using the bolt (#26), washer (#27),

nut (#33) stud bolts (#28) and external tooth washers

(#29).

7. Assemble the outer belt shield (#32) to the stud bolts

(#28) and retain with wing nuts (#30) and washers

(#31).

8. Assemble the hydraulic cylinder (#39) on to the pin

(#42) that is in the top spring support bracket. Retain

with pin (#40).

Section 1 Assembly and Set-Up