30 Dealer Service

MAN0826 (8/31/2010)

Seal Installation

NOTE: Proper seal installation is important. An improp-

erly installed seal will leak.

1. Clean area in housing where seal outer diameter

(OD) seats. Apply a thin coat of Permatex.

2. Inspect area of shaft where seal seats. Remove

any burrs or nicks with an emery cloth.

3. Lubricate gear shaft and seal lips.

4. Place seal squarely on housing, spring-loaded lip

toward housing. Select a piece of pipe or tubing

with an OD that will sit on the outside edge of the

seal but will clear the housing. Tubing with an OD

that is too small will bow seal cage and ruin seal.

5. Carefully press seal into housing, avoiding

distortion to the metal seal cage.

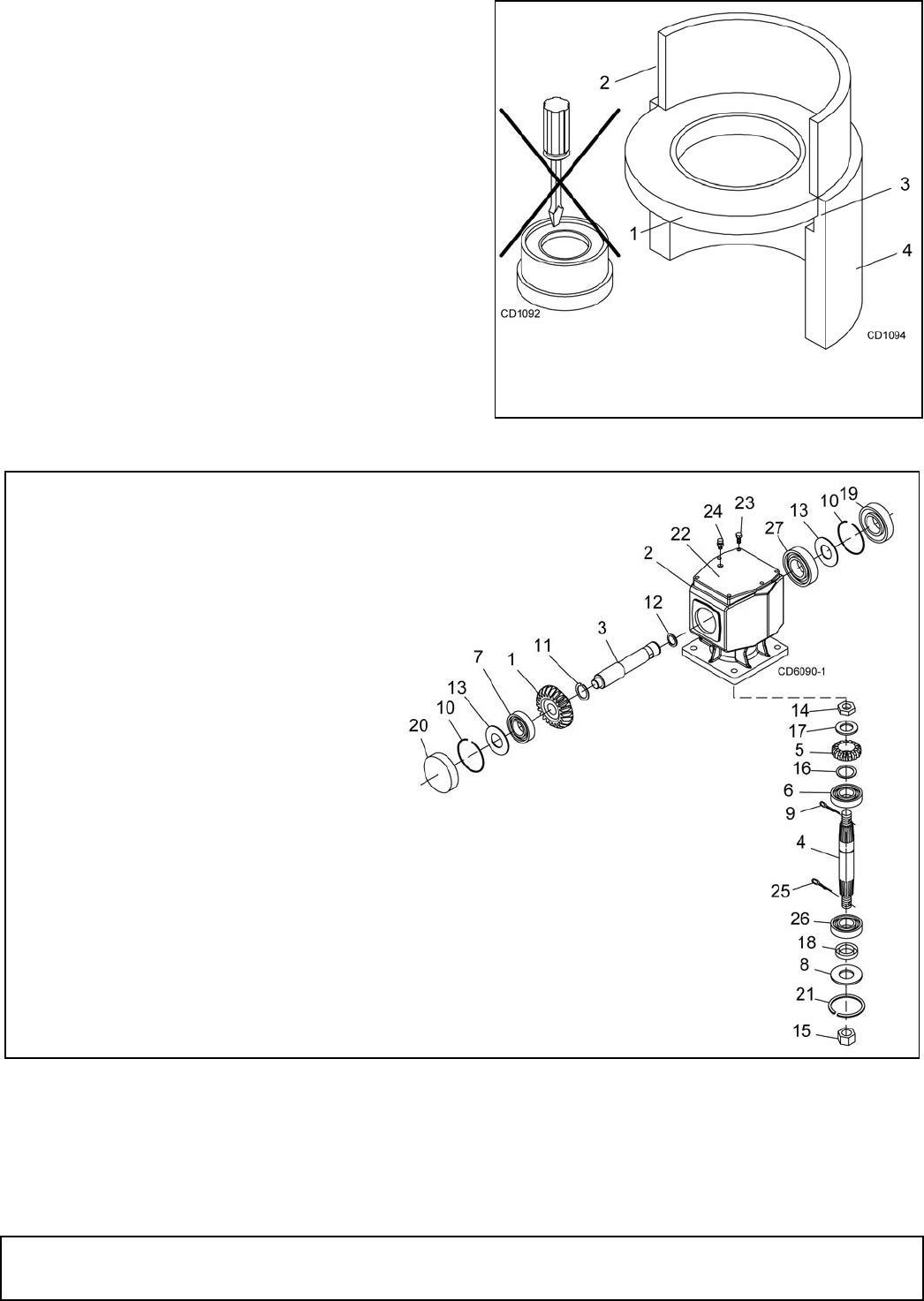

Figure 16. Seal Installation

Figure 17. Gearbox Assembly

Vertical Shaft Repair (Figure 17)

1. Disconnect and remove the driveline from the

gearbox.

2. Remove vent plug (24) and siphon gear lube from

housing through this opening.

3. Remove gearbox stand from mower deck.

4. Remove gearbox and pulley from gearbox stand.

1. Seal

2. Pipe or tube

3. Seal seat

4. Casting

NOTE: Pipe or tube must press at outer edge of seal.

Incorrect

Installation

1. Crown gear

2. Gearbox housing

3. Input shaft

4. Output shaft

5. Gear pinion

6. Bearing

7. Bearing

8. Protective flat washer

9. Cotter pin

10. Snap ring

11. Snap ring

12. Spacer

13. Shim kit

14. Castle nut

15. Castle nut M24 x 2

16. Shim kit

17. Flat washer

18. Oil seal (40 x 80 x 12)

19. Oil seal (35 x 72 x 10)

20. Cap

21. Snap ring

22. Top cover

23. Bolt M8 x 14mm

24. Breather plug

25. Cotter pin

26. Bearing

27. Ball bearing