22 Owner Service

5WPMAN0862 (11/22/2010)

BELT SERVICE

Belt Replacement

One of the major causes of belt failure is improper

installation. Before installing a new belt, check the fol-

lowing:

1. Check pulley shafts and bearings for wear.

2. Check pulley grooves for cleanliness.

3. Make sure spindles turn freely and without wobble.

If grooves require cleaning, moisten a cloth with a non-

flammable, non-toxic degreasing agent or commercial

detergent and water.

Avoid excessive force during installation. Do not use

tools to pry belt into pulley groove. Do not roll belt over

pulleys to install. This can cause hidden damage and

premature belt failure.

Belt Installation

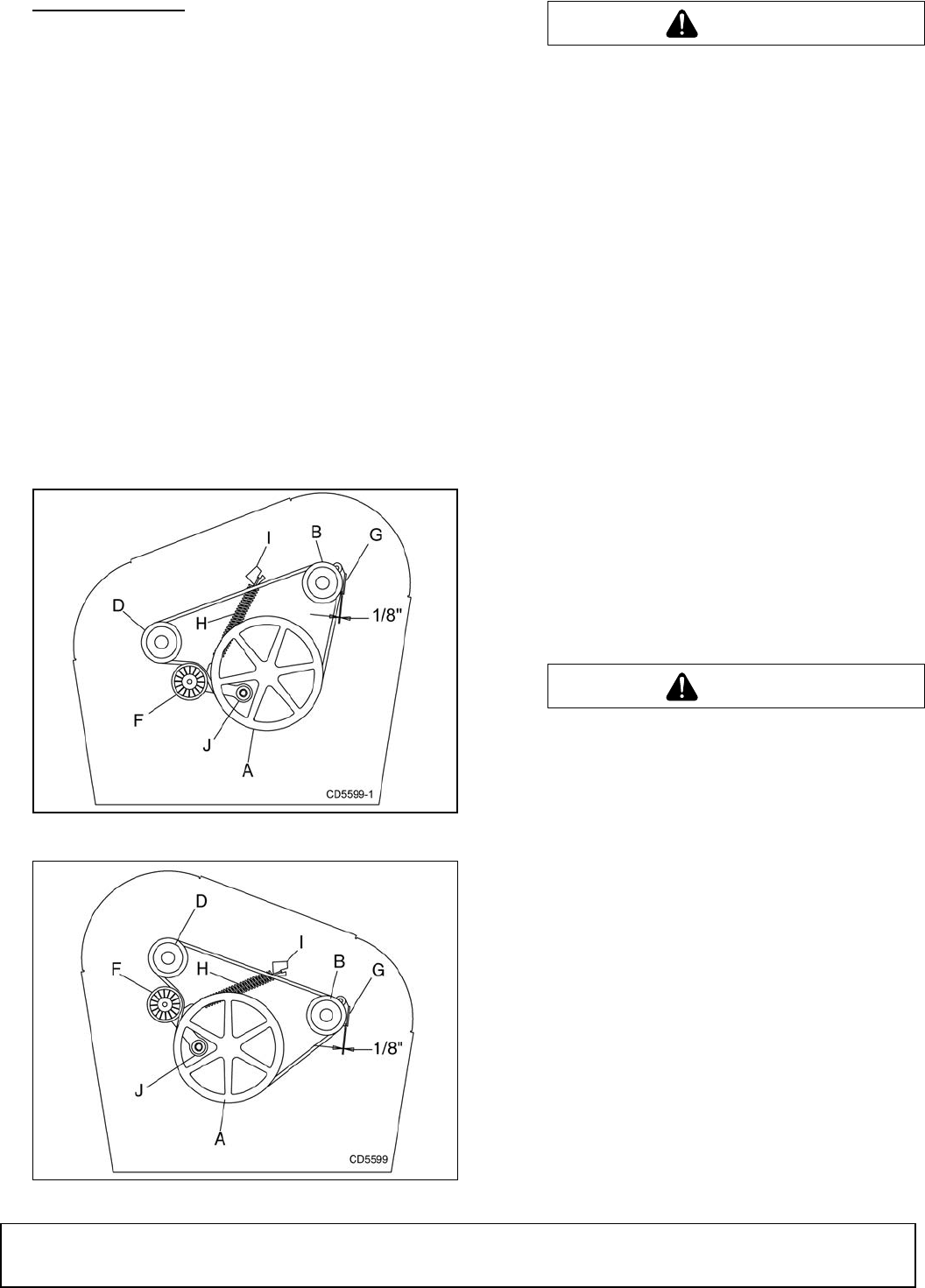

Wing Deck - FM1012 (Figure 9 & Figure 10)

Figure 9. Belt Routing Right Wing FM1012

Figure 10. Belt Routing Left Wing FM1012

Use care when installing or removing belt from

spring-loaded idler. Springs store energy when

extended and, if released suddenly, can cause per-

sonal injury.

4. Slide belt under drive pulley A and over idler arm.

Position the belt around drive pulley A.

5. Loosen the bolt holding belt guide G and swing it

away from pulley B. Route the belt around pulley D

as shown.

6. Make sure the belt is on drive pulley A; route

around idler F.

7. Grasp the belt between spindle pulley B and

spindle pulley D. Drive pulley A. Pull spring loaded

idler with belt to obtain enough belt length to route

it over pulley B. Make sure spring loaded idler

pivots freely with belt installed.

8. Adjust belt guide G to provide 1/16" to 1/8"

clearance from belt. Tighten the bolt to 85 lbs./ft.

Rear Deck - FM1012

All Decks - FM1015 & FM1017(Figure 11)

Use care when installing or removing belt from

spring-loaded idler. Springs store energy when

extended and, if released suddenly, can cause per-

sonal injury.

1. Slide the belt under drive pulley A and over idler

arm. Position the belt around drive pulley A.

2. Loosen the bolt holding belt guide G and swing it

away from pulley B. Route the belt around pulley B,

idler C, and pulley D as shown.

3. Make sure the belt is on drive pulley A; route

around idler F.

4. Grasp the belt between spindle pulley E, spring

loaded idler F, and spindle pulley D. Pull spring

loaded idler with belt to obtain enough belt length

to route it over pulley E. Make sure spring loaded

idler pivots freely with belt installed.

5. Adjust belt guide G to provide 1/16" to 1/8"

clearance from belt. Tighten bolt to 85 lbs-ft.

CAUTION

CAUTION