7

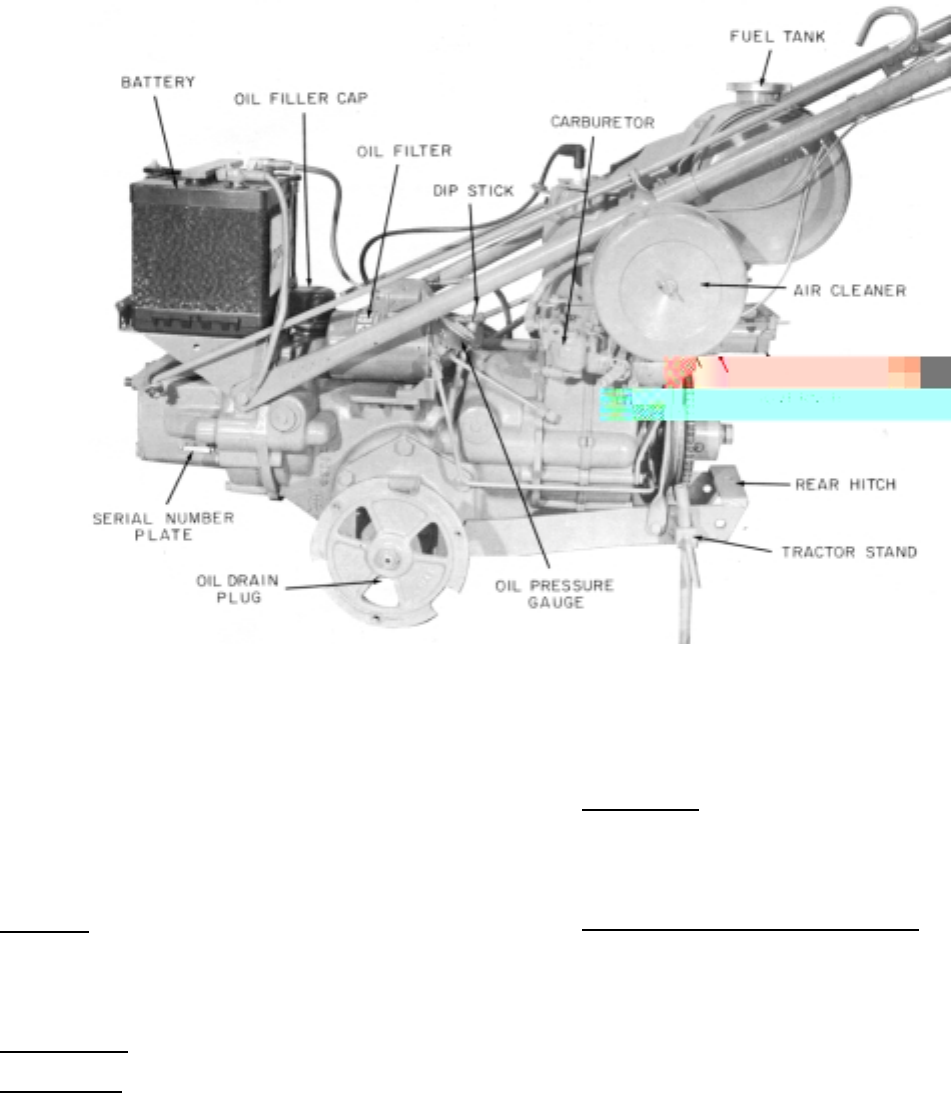

Figure 5

MAINTENANCE

LUBRICATION

Filling the chassis to its 5 pint (2.36L.) capacity with motor

oil lubricates both the engine and transmission. Do not

use transmission oil or grease. The following is

recommended:

Summer - SAE 30 or SAE 10W-30. API Classification -

SC or SD

Winter - (32 degrees F or below) SAE 10W or SAE

10W-30 API Classification - SC or SD

Oil Level

- Regularly check the oil level with the Dipstick

(figure 5) before starting. Be sure the tractor is level.

Add oil - Add oil by removing the Oil Filler Cap (Figure 5 .

Stop when the oil reaches the FULL mark on the

dipstick. (Allow time for the oil to drain down prior to

checking. This prevents overfilling.)

Oil Filler Cap

- Periodically check the breather-type oil

filler cap. Wash it in solvent at least every oil change.

Oil Changes

- Change the oil after the initial eight hours

of operation. Then change the oil every 40 hours under

normal conditions, oftener under dusty conditions

and/or periods of extended operation under heavy

load.

Drain oil by removing the oil drain plug, the bottom bolt on

the Left Hand axle housing.

Be sure oil drain washer is in place when replacing the

bolt.

Oil Filter - Under normal conditions, change the oil filter

every 80 hours, however, under extremely dusty

conditions and/or extended operation under

heavy loads, change the oil filter every 40 hours.

The oil filter must be installed by hand. Install the filter

following the instructions printed on the filter.

Oil Pressure

- Check the oil pressure gauge when

starting. The level should raise quickly after starting,

and at full throttle be about 2/3 of the way over in the

normal range. If the oil pressure is not correct, stop the

engine and check oil level. If the oil level is not low,

check your service manual or call your dealer.

Battery (Electric Start models only)

- daily check the

electrolyte level o the battery. Maintain at proper level

by adding only distilled water.

AIR INTAKE SYSTEM

The importance of maintaining an air cleaner in proper

condition cannot be over-emphasized! Dirt induced

through improperly installed, improperly serviced

elements, wears out more engines than does long

hours 'of operation. Furthermore, operating with a

clogged element causes a richer fuel mixture which can

lead to formation of harmful sludge deposits. Always

cover carburetor or air horn when air cleaner is

removed for servicing.

Dry type air cleaner elements should be serviced only

when required. Need for air cleaner service is evident

by a loss of power for no apparent reason.

To clean, remove element and tap lightly on a flat surface

to remove loose surface dirt. Replace element if dirt

does not drop off easily or if the element is