15

plate attached to the Hopper. Simply set the Port Lever to

the indicate opening to distribute seed or fertilizer

properly.

Care of Hopper Assembly: Many materials used in the

Seeder-Spreader, especially certain fertilizers, are

corrosive. Abrasives also are present. This means the

protective paint soon will wear off the Port Assembly

and Agitator. To protect these surfaces,

wash the Seeder-Spreader thoroughly with water after

using and let it dry, preferably in the sun. If you do not

intend to use it again within a few days, pour a small

quantity of oil along the Port Openings and work the

Port Lever back and forth to distribute the oil.

TWIN-TOOL GARDENING

ROTARY PLOW AND ROTARY CULTIVATOR

A

final cutting depth adjustment, is required, is made by sliding

the Wheel Bracket Clamp, (1 in Figure 24), up or down in the

slitted Wheel Bracket. The lower the Clamp is set, the lower

de

p

th of cut.

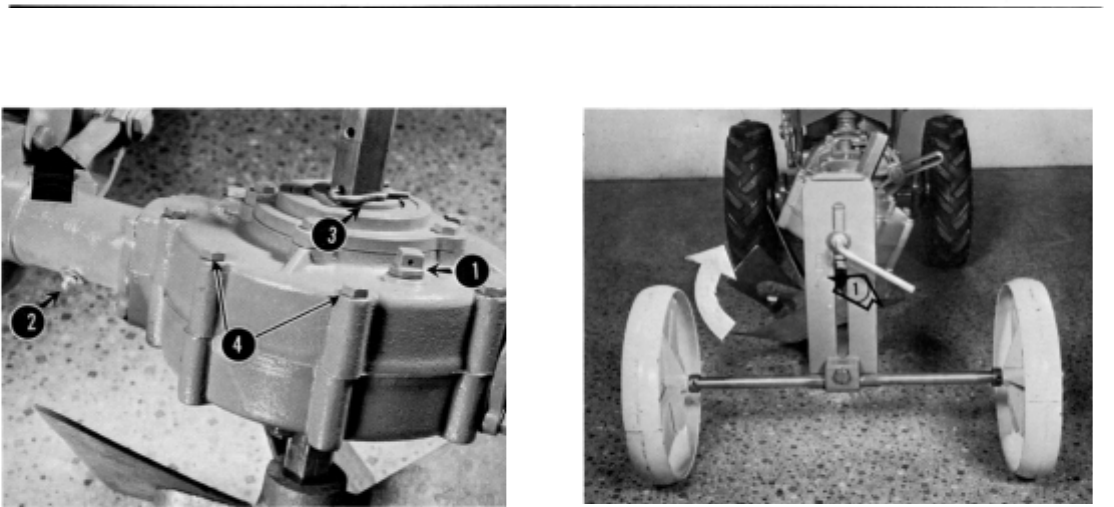

Figure 23 Figure 24

The Rotary Plow is attached to the Tractor by two Nuts and

two Bolts. One Bolt and one Nut must be used to attach

the Angle Adjusting Bracket, upper left in Figure 23.

LUBRICATION

Check the Gear Housing oil level every eight hours of

operation. Gear Housing capacity is 1 1/2 pints. Use

SAE 140 or 90W EP gear lubricant.

Add oil by removing the Oil Filter Plug (I in Figure 20). Use

occasionally General Purpose Grease in the swivel

casting grease fitting, (2 in Figure 23).

SAFETY PRECAUTIONS

1. Do not let anyone operate the unit without proper

instructions.

2. Keep all shields and safety devices in place.

3. Disengage power to any attachment and stop engine

prior to making adjustments.

4. Pay attention to what you are doing.

5. Don't wear loose fitting clothing that might get caught in

moving parts. Keep hands and feet away from moving

parts.

ADJUSTMENTS

Depth of Cut Adjustment

Use the pin or clip, (3 in Figure 23), in the Hex Shaft for

initial Cutting depth adjustment. The higher on the Shaft

the Pin is inserted, the greater the depth of cut and vice

versa. Ordinarily, the Pin is inserted in one of the top

holes for plowing and in the bottom hole for transporting.

Plowing Angle Adjustment

When plowing for the first time, set the Plow at the

approximate angle to the ground as shown in Figure 24.

The Nut which secures the Angle must be loosened to do

this; be sure it is tightened firmly after the proper angle is

set.

The bolt through angle adjusting bracket should be

about 3/4 inch (19.05cm) from the bottom of the slot.

If there is excessive drag to the left (left, as you stand

at the handles) move the Plow in the direction of the

arrow in Figure 24. If there is excessive drag to the right,

move the Plow opposite the direction of the arrow.

A few trials may be required before the Plow is

adjusted properly to soil conditions.

Width of Cut Adjustment

The width of cut is governed by the position of the

Wheel Bracket in relation to the Depth Wheel in the

furrow. The closer the Wheel Bracket is to the Depth

Wheel in the furrow, the narrower the cut, and vice versa.

DIRT SHIELD

The Dirt Shield is attached to the top of the Gear

Housing by removing the bolts, (4 in Figure 23). inserting

them through the Shield, and replacing in the Gear

Housing. You can use the Dirt Shield to direct the throw

of the dirt, by bending it up or down.