9

Figure 8

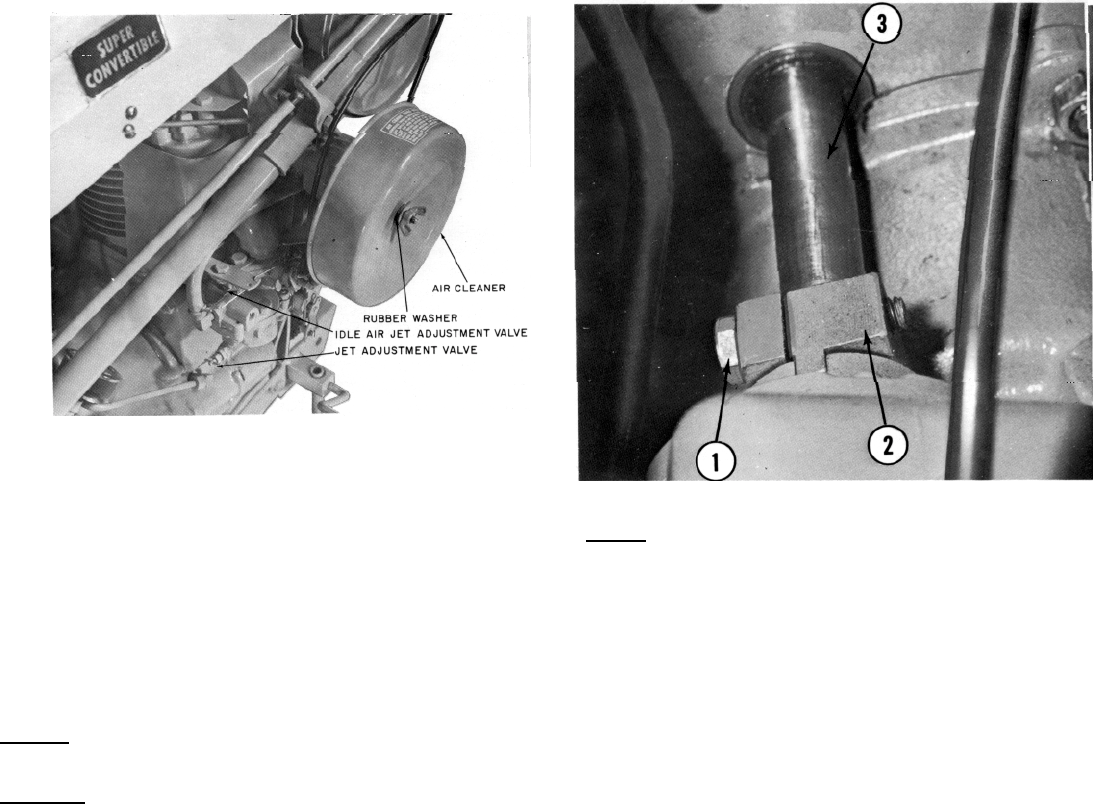

Figure 9

1. Screw the jet adjustment valve (a brass T-valve) in

until it is snug. Do not force or screw it tightly.

2. Back off the jet adjustment valve 1 1/2 turns.

3. Start the engine and open the throttle halfway. After

the engine warms up, begin screwing the jet

adjustment valve in slowly. As soon as the engine

slows down, stop and back the valve off until engine

picks up speed.

4. Screw the idle air jet adjustment valve (a slotted

head screw with a spring around it) all the way in;

then back off 1 turn. Start the engine and allow it to

idle. Screw the idle air jet adjustment valve in until

the engine begins to run rough. Then back the valve

off the engine runs smooth.

Valves

- Adjust the valves only when the engine is cold.

Remove the valve cover cap, adjust tappet to .015

(.397mm) inch.

Fan Belt

- Fan belt tension is adjusted by moving the fan

belt pulley (the pulley at the fan) upwards, to increase

tension. To adjust; loosen the large thin nut between

the fan belt pulley and fan housing. Tighten after

proper tension is reached.

Timing

- The magneto should be set to fire approximately 20

degrees before top dead center. To adjust:

1. Loosen magneto coupling nut (1, Figure 9) until the

coupling slips on the camshaft. It may be necessary to

tap the coupling gently.

2. Remove the cylinder head.

3. Bring the piston to top dead center on the compression

stroke (both valves closed).

4. Turn the starter pulley counterclockwise until the piston

goes down the cylinder approximately one inch. Then

bring the piston back up the cylinder to 3/8 inch

(9.525mm) from top of cylinder. This procedure takes up

any backlash in the gears.

5. Align the timing marks (straight marks) on the magneto.

6. Be sure that there is at least .015 inch (.397mm.) end

play in the magneto coupling so it will not cramp the

impulse. Use feeler gauge between the fiber block (2,

Figure 9) before tightening nut. Tighten nut.

7. Check your settings by backing the piston not more than

two inches down the cylinder barrel (to avoid picking up

the magneto impulse) and bring the piston up to 3/8 inch

from top of cylinder, magneto marks should align.

8. When timing is correct, install cylinder head and

magneto cover.

SPECIFICATIONS

Model Custom Super

Engine Gravely Gravely

Type 4-cycle air cooled 4-cycle air cooled

Horsepower 7.6 7.6

Bore & Stroke 3.25 x 3.50 (82.55mm x 88.80mm) 3.25 x 3.50 (82.55mm x 88.80rnm)

Displacement 29.0 cu. inch(475.Icc) 29.0 cu. in. (475.1 cc)

Speed 2600-2800 RPM 2600-2800 RPM

Valve Setting .015 in. (.397 mm) .015 in. (.397mm)

Fuel Regular Regular

Capacity

Fuel Tank 1.75 U. S. Gal. (6.63L) 1.75 U. S. Gal. (6.63L)

Chassis 5 pts. (2.36L) 5 pts. (2.36L)