GB - 19

To clean terminals:

1. Remove battery cover.

2. Remove battery cables from terminals.

3. Clean or service battery away from unit. Remove

corrosion from battery terminals and cable

connections with wire brush, then wash with a

weak baking soda solution.

4. Apply a thin coat of dielectric grease or petroleum

jelly to terminals and cable ends to retard

corrosion.

5. Replace battery and secure with battery cover.

CHECK ALL BELTS

Check all belts for wear or damage every 25 hours. If

belts slip, check for damaged belts or tensioner.

MOWER BLADES

Check mower blades for wear every 25 hours of

operation. Ensure blade hardware is tightened to

115-125 lbf-ft (156-169.5 N•m) of torque.

CLEAN AIR CLEANER FOAM ELEMENT

See engine manual for detailed instructions.

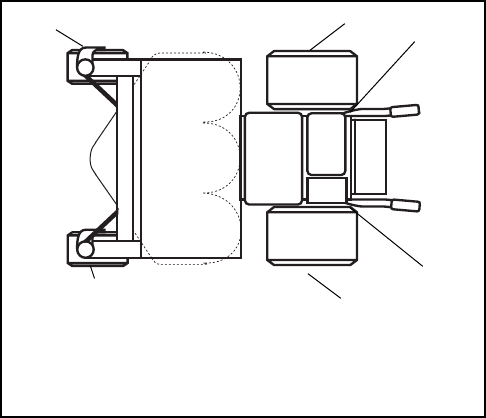

GENERAL LUBRICATION

Apply a small amount of oil to the pivot points as

required for smooth operation (Figure 8).

Apply high quality lithium based grease to all lube

fittings every 50 hours of operation.

NOTE: The mower spindle assembly is maintenance

free.

CHANGE ENGINE OIL

Open the petcock to drain oil through oil drain hole on

left side of engine. See engine manual for additional

instructions.

CHECK FUEL FILTER

See engine manual for detailed instructions.

CHECK SPARK PLUG

See engine manual for detailed instructions.

CHECK MUFFLER

Check muffler for damage or wear. Replace if

necessary.

CLEAN AIR CLEANER PAPER ELEMENT

See engine manual for detailed instructions.

CHANGE HYDRAULIC FLUID AND FILTER

Change hydraulic fluid and filter after the first 50 hours

of operation. They both should be changed every 500

hours thereafter.

To change the filter:

1. Place open container under tank. The container

should be able to hold at least 4 quarts of oil.

2. Remove tank from frame and allow tank to tip

rearward to allow oil to drain from system

(Figure 9).

3. After most of the oil has drained, turn the tank

upside down counterclockwise to allow the rest of

the oil to drain.

4. Clean around filter.

5. Turn filter counterclockwise to remove.

6. Fill the oil filter with about 8 oz. (236 ml) of

hydraulic oil.

7. Apply a thin coat of oil onto seal of new filter.

8. Install new filter and hand tighten securely.

9. Fill system with about 44 oz. (1.3L) fresh, clean

hydraulic oil. See Specifications for proper type.

10. Run-in hydraulic system to bleed and lubricate

components. See below.

Figure 8

1. Wheel Bearings

2. Flange Bushings

1

2

2

1

OG1480

1

1