1.3 BEFORE INSTALLATION

Before installing this equipment, check the ratings of both

the generator and the transfer switch. Read “Emergency

Circuit Isolation Method” and “Total Circuit Isolation

Method” in Sections 1.8 and 1.9 (Page 11) carefully.

The generator's rated wattage/amperage capacity

must be adequate to handle all electrical loads that

the unit will power. You may have to group the criti-

cal (essential) electrical loads together and wire them

into a separate emergency distribution panel.

NOTE:

In some areas, you may need to acquire electrical

permits for installing an emergency system, build-

ing permits for installing gas lines, and permits for

noise allowances. Check your local codes before

installing the unit.

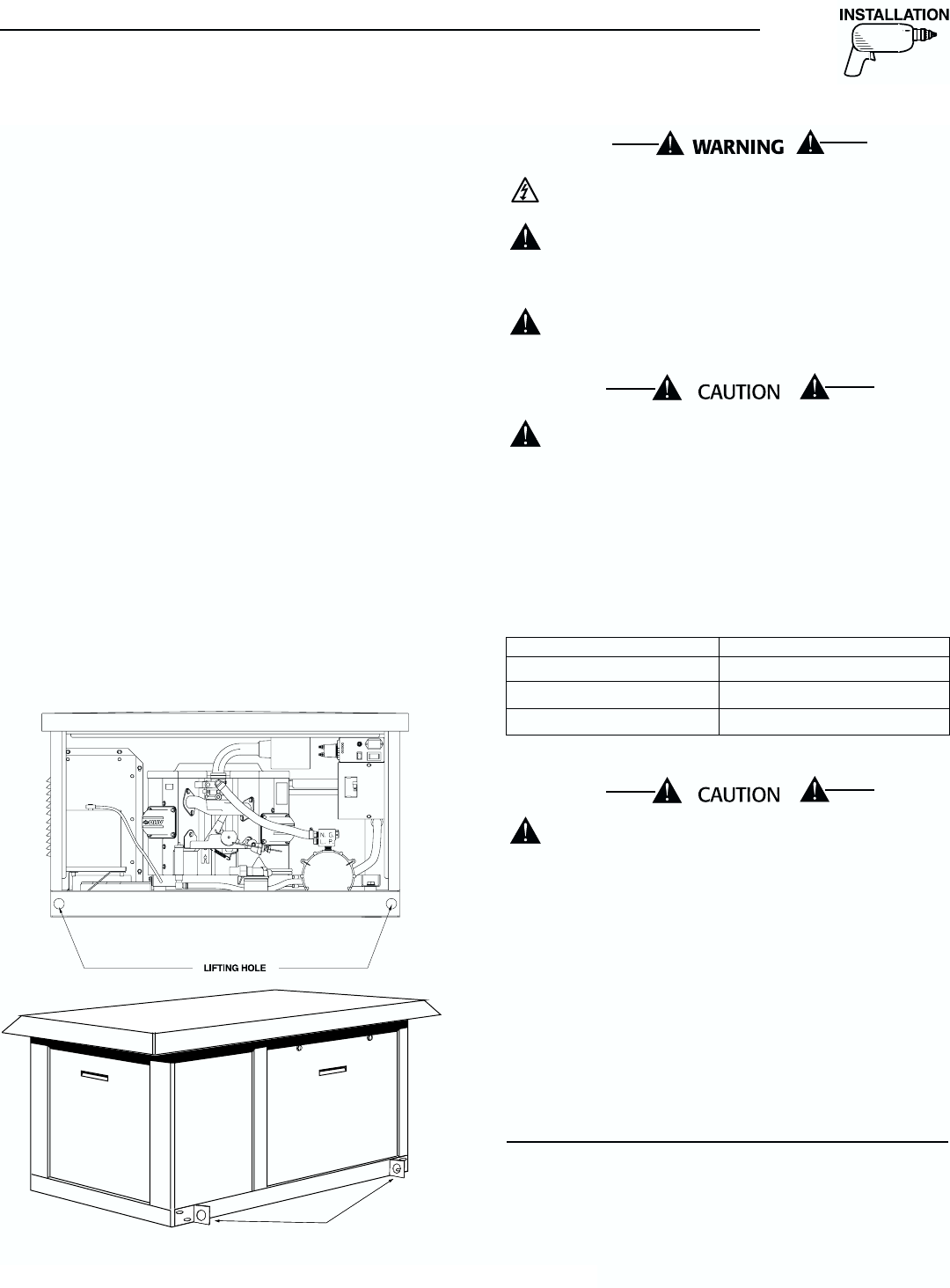

1.4 LIFTING THE GENERATOR

To lift a nonsound attenuated generator, insert pipe

having sufficient strength and diameter through the lift-

ing holes (lifting brackets are provided with sound

attenuated units), which are located near the unit’s base

(see Figure 1.1). You also may lift the unit using a hook

and hoist method provided you use a spreader bar to

ensure that the lines clear the roof.

Figure 1.1 – Location of Lifting Holes/Brackets

When lifting or hoisting equipment is used, be

careful not to touch overhead power lines.

The generator’s weight of more than 300

pounds requires proper tools and equipment,

and qualified personnel to be used in all phases

of handling and unpacking.

Exercise caution when lifting the unit

manually as it may shift on lifting pipes during

transportation, which may result in injury.

The generator was not designed to be lifted by

its roof. Use the lifting holes or brackets provided

near the base of the unit. If using a hook and

hoist lifting method, you must employ a spreader

bar to prevent from crushing the roof.

1.5 ENGINE OIL RECOMMENDATIONS

Use oil of American Petroleum Institute (API) Service

Class SG, SH or SJ. Select the viscosity based on the

air temperature at the time of operation. See the fol-

lowing chart:

*Organic break-in oil is required before using synthetic oil.

Any attempt to crank or start the engine before

it has been properly serviced with the recom-

mended oil may result in an engine failure.

1.6 GASEOUS FUEL SYSTEM

NOTE:

The following information pertaining to gaseous

fuel systems is provided to assist gaseous fuel

technicians in planning installations. In no way

should this information be interpreted to conflict

with applicable fuel gas codes. Consult with your

local fuel supplier or fire marshall if questions or

problems arise.

1.6.1 FUEL SYSTEM REQUIREMENTS

AND RECOMMENDATIONS

When installing the fuel system, install a flexible

length of line between the generator fuel connec-

tion and the rigid piping. The flexible hose must

be approved for use with gaseous fuels. It is rec-

ommended that an emergency manual fuel shutoff

valve be placed in-line.

◆

LIFTING BRACKET

Section 1 — Installation

Guardian Air-cooled Generators

Generac

®

Power Systems, Inc. 5

Temperature Oil Grade (Recommended)

Above -7º C (20º F) SAE 10W-30 or SAE 30

Below -7º C (20º F) SAE 5W-20 or 5W-30

All Seasons SAE 5W-30 Synthetic*

(6 kW, 8 kW and 10 kW)

(Sound Attenuated)