24 Generac

®

Power Systems, Inc.

3.7 ENGINE GOVERNOR ADJUSTMENT

If both AC frequency and voltage are correspondingly

high or low, adjust the engine governor as follows:

3.7.1 6 KW UNITS (NON-SA)

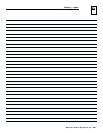

1. Loosen the governor clamp bolt (Figure 3.1).

2. Push the spring end of the governor lever clock-

wise to the wide open throttle position of

the lever.

• Hold the governor lever at wide open throttle and,

with a pair of pliers, rotate the governor shaft

fully clockwise.

• While holding the governor shaft fully clockwise

and the governor lever at wide open throttle,

tighten the governor clamp bolt to 70 inch-

pounds (8 N-m).

3. Start the engine; let it stabilize and warm up at

no-load.

4. Turn the adjuster nut to obtain a frequency read-

ing of 62 Hertz.

5. Determine if the governor spring is properly

located in the slot of the governor lever as

follows:

• If droop is excessive, move the governor spring

down one slot on the lever.

• For greater stability, move the governor spring up

one slot on the lever.

6. After repositioning the spring on a lever slot,

recheck the frequency reading and, if necessary,

readjust the adjuster nut to obtain 62 Hertz at

no-load.

7. When frequency is correct at no-load, check the

AC voltage reading. If voltage is incorrect, the volt-

age regulator may require adjustment.

Figure 3.1 – 6 kW

Engine Governor Adjustment

3.7.2 8 KW AND 10 KW UNITS (NON-SA)

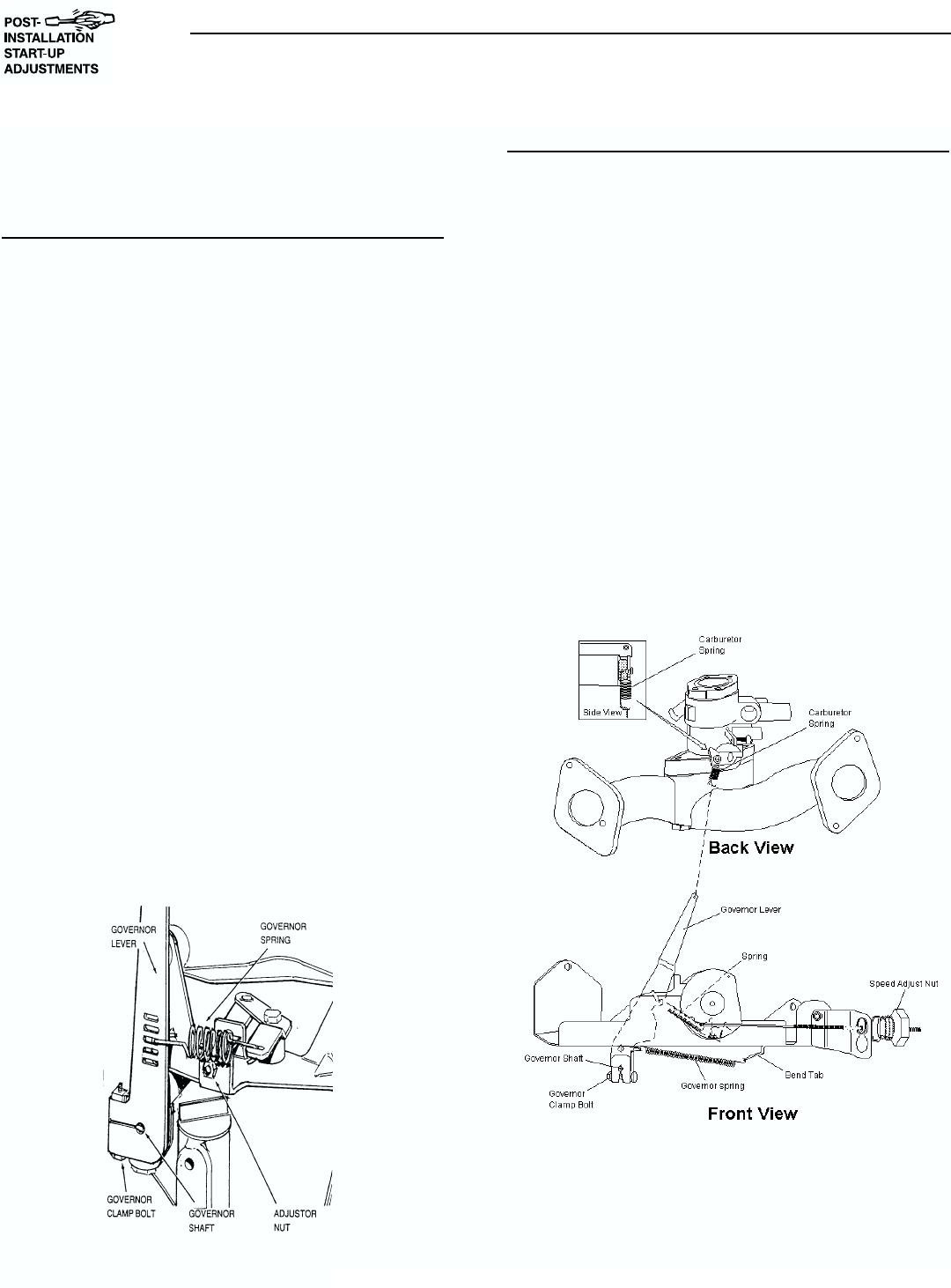

1. Loosen the governor clamp bolt (Figure 3.2).

2. Push the spring end of the governor lever clock-

wise to the wide open throttle position of

the lever.

• Hold the governor lever at wide open throttle

and, with a screwdriver, rotate the governor

shaft fully clockwise.

• Before tightening, verify that the governor lever is

pushed all the way onto the governor shaft.

• While holding the governor shaft fully clockwise

and the governor lever at wide open throttle,

tighten the governor clamp bolt to 70 inch-

pounds (8 N-m).

3. Start the engine; let it stabilize and warm up at

no-load.

4. Turn the speed adjust nut to obtain a frequency

reading of 62 Hertz.

5. When frequency is correct at no-load, check the

AC voltage reading. If voltage is incorrect, the volt-

age regulator may require adjustment.

Figure 3.2 – 8 kW and 10 kW

Engine Governor Adjustment

NOTE:

If the engine continues to run fast, use a pair of

pliers to bend the bend tab clockwise to release

tension on the lower governor spring.

◆

◆

Section 3 — Post-installation Start-up Adjustments

Guardian Air-cooled Generators