/;\

The battery represents a risk of high short

illcircuit

current. When working on the battery,

always remove watches, rings or other metal

objects, and only use tools that have insulated

handles.

An

authorized

operator

should

inspect

the

engine

battery

system

monthly

(or

100

hours).

At

this

time,

the

battery

fluid

level

should

be

checked

and

distilled

water

added

if

needed.

Battery

cables

and

connections

also

should

be

inspected

for

cleanliness

and

corrosion.

Once

every

six

months

(or

200

hours),

an

Authorized

Service

Technician

'should

inspect

the

battery

system.

At

this

time

the

battery

condition

and

state

of

charge

should

be

checked

using

a

battery

hydrometer.

The

battery

should

be

recharge

or

replaced

as

required.

CHECK

FLUIDS

An

authorized

operator

should

check

the

levels

of

engine

oil,

and

engine

coolant

monthly

(or

100

hours).

The

oil

level

should

be

maintained

between

the

"FULl:'

and

"ADD"

marks

on

the

engine

dipstick.

Recommended

fluids

are

listed

are

in

the

"Specifications"

section.

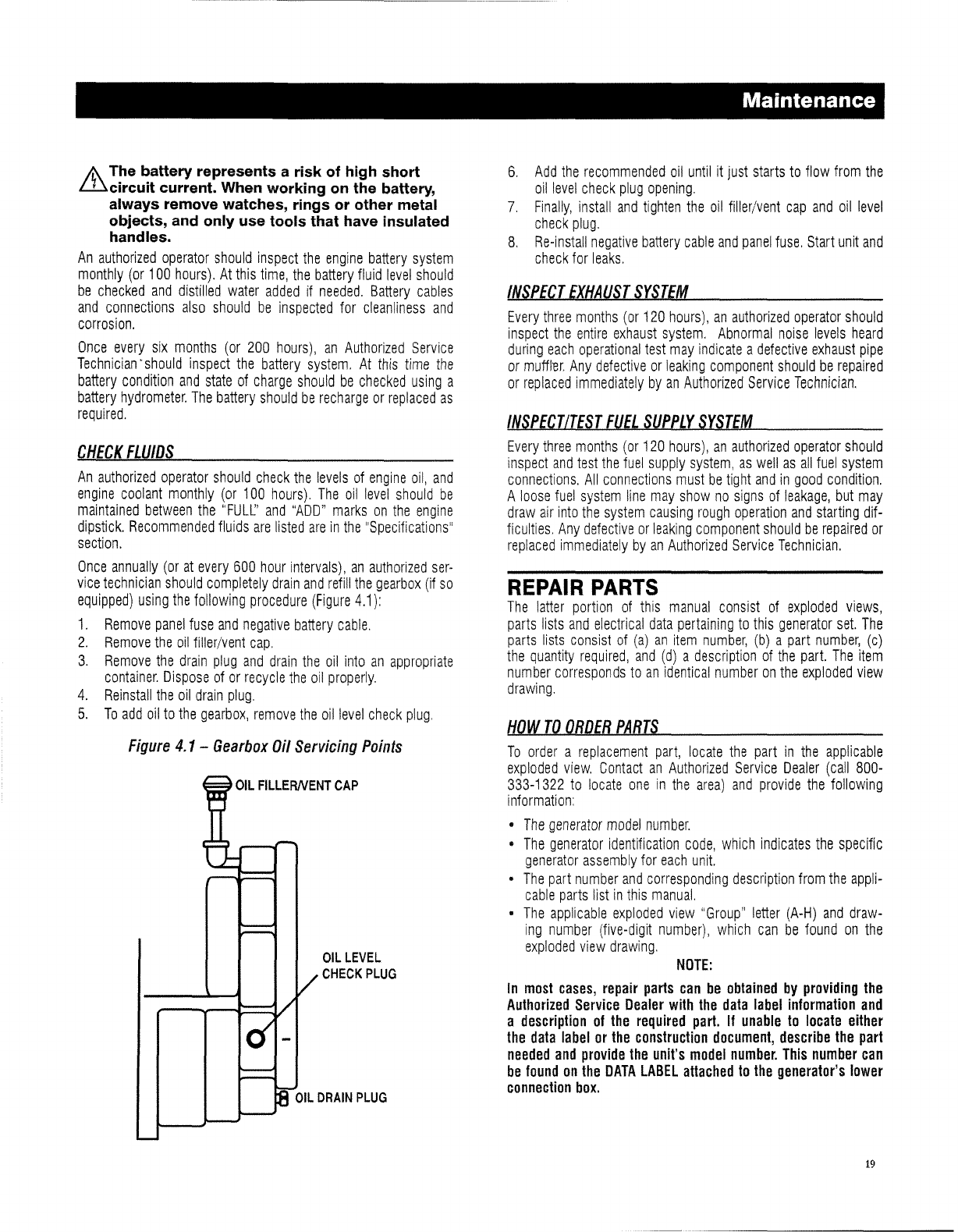

Once

annually

(or

at

every

600

hour

intervals),

an

authorized

ser-

vice

technician

should

completely

drain

and

refill

the

gearbox

(if

so

equipped)

using

the

following

procedure

(Figure

4.1):

1.

Remove

panel

fuse

and

negative

battery

cable.

2.

Remove

the

oil

filler/Vent

cap.

3.

Remove

the

drain

plug

and

drain

the

oil

into

an

appropriate

container.

Dispose

of

or

recycle

the

oil

properly.

4.

Reinstall

the

oil

drain

plug.

5.

To

add

oil

to

the

gearbox,

remove

the

oil

level

check

plug.

Figure

4.1

-

Gearbox

Oil

Servicing

Points

OIL

FILLERNENT

CAP

OIL

LEVEL

CHECK

PLUG

Maintenance

6.

Add

the

recommended

oil

until

it

just

starts

to

flow

from

the

oil

level

check

plug

opening.

7.

Finally,

install

and

tighten

the

oil

filler/Vent

cap

and

oil

level

check

plug.

8.

Re-install

negative

battery

cable

and

panel

fuse.

Start

unit

and

check

for

leaks.

INSPECT

EXHAUST

SYSTEM

Every

three

months

(or

120

hours),

an

authorized

operator

should

inspect

the

entire

exhaust

system.

Abnormal

noise

levels

heard

during

each

operational

test

may

indicate

a

defective

exhaust

pipe

or

muffler.

Any

defective

or

leaking

component

should

be

repaired

or

replaced

immediately

by

an

Authorized

Service

Technician.

INSPECT/TEST

FUEL

SUPPLY

SYSTEM

Every

three

months

(or

120

hours),

an

authorized

operator

should

inspect

and

test

the

fuel

supply

system,

as

well

as

all

fuel

system

connections.

All

connections

must

be

tight

and

in

good

condition.

A

loose

fuel

system

line

may

show

no

signs

of

leakage,

but

may

draw

air

into

the

system

causing

rough

operation

and

starting

dif-

ficulties.

Any

defective

or

leaking

component

should

be

repaired

or

replaced

immediately

by

an

Authorized

Service

Technician.

REPAIR

PARTS

The

latter

portion

of

this

manual

consist

of

exploded

views,

parts

lists

and

electrical

data

pertaining

to

this

generator

set.

The

parts

lists

consist

of

(a)

an

item

number,

(b)

a

part

number,

(c)

the

quantity

required,

and

(d)

a

description

of

the

part.

The

item

number

corresponds

to

an

identical

number

on

the

exploded

view

drawing.

HOW

TO

ORDER

PARTS

To

order

a

replacement

part,

locate

the

part

in

the

applicable

exploded

view.

Contact

an

Authorized

Service

Dealer

(call

800-

333-1322

to

locate

one

in

the

area)

and

provide

the

following

information:

•

The

generator

model

number.

•

The

generator

identification

code,

which

indicates

the

specific

generator

assembly

for

each

unit.

•

The

part

number

and

corresponding

description

from

the

appli-

cable

parts

list

in

this

manual.

•

The

applicable

exploded

view

"Group"

letter

(A-H)

and

draw-

ing

number

(five-digit

number),

which

can

be

found

on

the

exploded

view

drawing.

NOTE:

In

most

cases,

repair

parts

can

be

obtained

by

providing

the

Authorized

Service

Dealer

with

the

data

label

information

and

a

description

of

the

required

part.

If

unable

to

locate

either

the

data

label

or

the

construction

document,

describe

the

part

needed

and

provide

the

unit's

model

number.

This

number

can

be

found

on

the

DATA

LABEL

attached

to

the

generator's

lower

connection

box.

19