ASSEMBLY

Final Inspection and Adjustments

IMPORTANT: PTO driveline may be too long for some tractor models, causing tractor transaxle damage.

Modify driveline if necessary.

Attach rotary cutter to tractor and check cutter-to-tractor driveline telescoping length clearance.

(See CHECKING DRIVELINE/CUTTER CLEARANCE in Attaching section.)

IMPORTANT: Blade hardware MUST be checked after the fi rst hour and every eight (8) hours thereafter.

Check blade hardware torque. Re-tighten hardware after one hour of operation and every eight (8) hours thereafter.

(See MAINTENANCE BEFORE EACH USE in Lubrication and Maintenance section.)

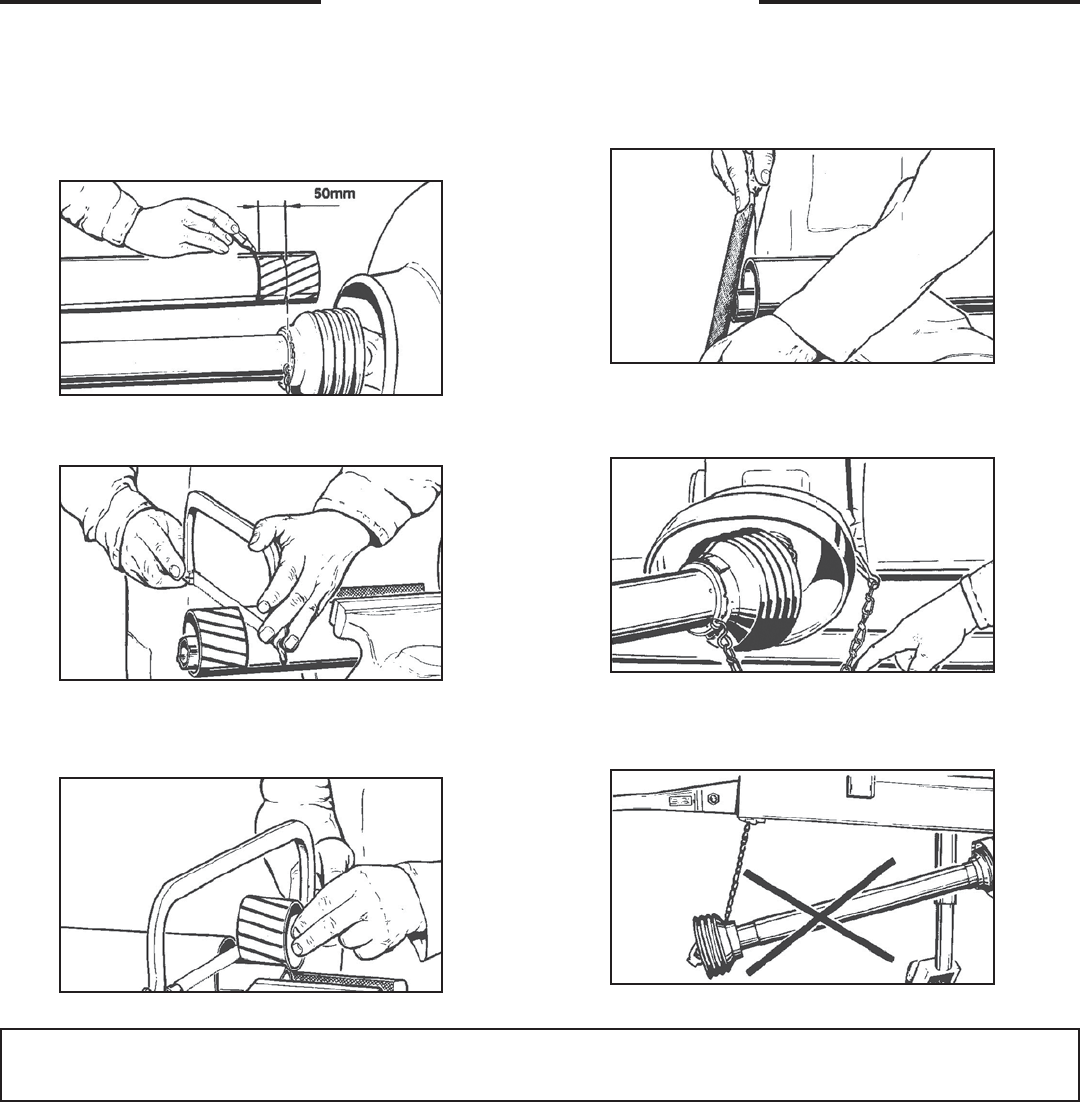

• Modify PTO Driveline (If Necessary)

1. To adjust the length, hold the half-shafts next

to each other in the shortest working position

and mark them.

2. Shorten inner and outer guard tubes equally.

3. Shorten inner and outer sliding profi les by

the same length as the guard tubes.

4. Round off all sharp edges and remove burrs.

Grease sliding profi les. No other changes

may be made to PTO drive shaft and guard.

5. Chains must be fi tted so as to allow suffi cient

articulation of the shaft in all working positions.

6. The PTO drive shaft must not be suspended

from the chains!

Assembly 33

MODIFY PTO DRIVELINE