SERVICE

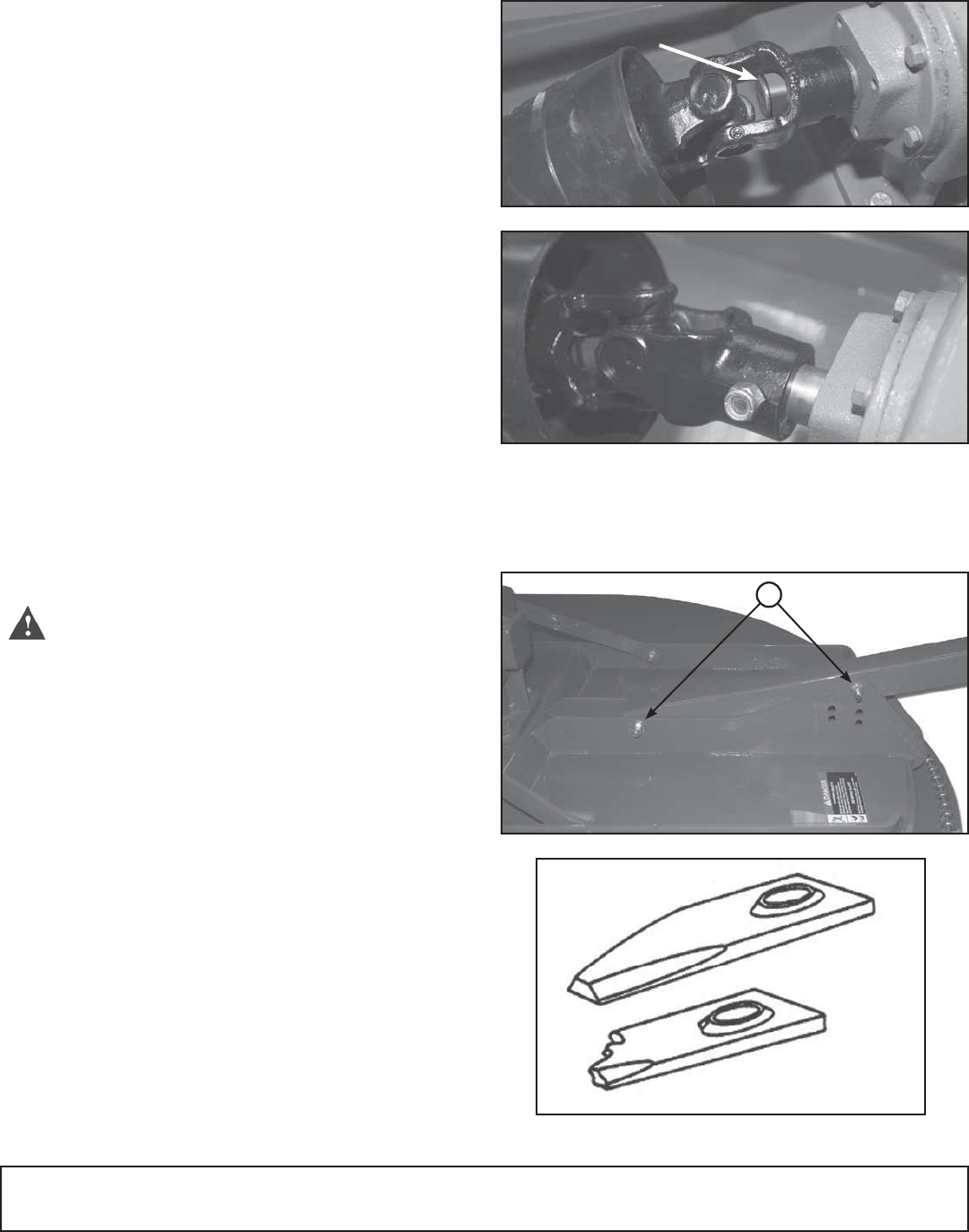

• Removing and Installing Driveline-Shear Bolt

1. Disconnect driveline shield chain.

2. Bend back driveline shield cone.

3. Remove shear bolt and lock nut.

4. Push driveline onto input shaft toward gearbox

and remove snap ring.

5. Pull driveline from gearbox shaft.

6. Replace or repair as necessary.

7. Install in reverse order of removal.

• Replacing Driveline Shear Bolt

IMPORTANT: Avoid shear bolt failure at start up

by engaging the PTO slowly at low engine rpm

.

If shear bolt fails:

1. Bend back driveline shield cone.

2. If necessary remove sheared bolt with hammer

and punch and realign holes in yoke and shaft.

3. Replace with 1/2” x 3 1/2” Gr 2 bolt and lock nut.

• Removing and Installing Tailwheel Support

CAUTION: When removing and installing

tailwheel support, it will be necessary to support

the cutter. Before servicing cutter, refer to

PRACTICE SAFE SERVICE PROCEDURES

at the beginning of this section.

1. Remove 1/2” lock nut, washers and 1/2” x 4”

bolt (A).

2. Remove tailwheel support.

3. Install tailwheel support in reverse order.

• Checking Blade Wear

IMPORTANT: Operating with blades that are not alike

will cause vibration. Always replace worn or broken

blades in pairs. Never replace a single blade.

Check blades regularly for wear or breakage.

NOTE: Driveline shield pulled back for illustration

purposes. Cutter drive components are

protected from shock loads by a shear bolt.

Snap Ring

A

(For models RC2048, RC2060 & RC2072)

(For models RC2048, RC2060 & RC2072)

(For models RC2048, RC2060 & RC2072)

Service 25