ASSEMBLY

• Perform Predelivery Service Safely

CAUTION: Understand the predelivery

procedure before doing the work.

During the assembly, test, and adjustment procedures,

it may be necessary to operate drives and hydraulic

systems. Stay clear of machine elements when raising

or lowering machine and during operation of drivelines.

Practice good communication with other service

technicians. Be aware of their actions and alert them

to potential hazards.

Never lubricate, service, or adjust machine while it

is running. Keep hands, feet, and clothing away from

power-driven or hydraulically operated parts. If it is

necessary to inspect the machine while it is in operation,

be alert to moving parts in the immediate area.

• Remove Shipping Dunnage and Parts

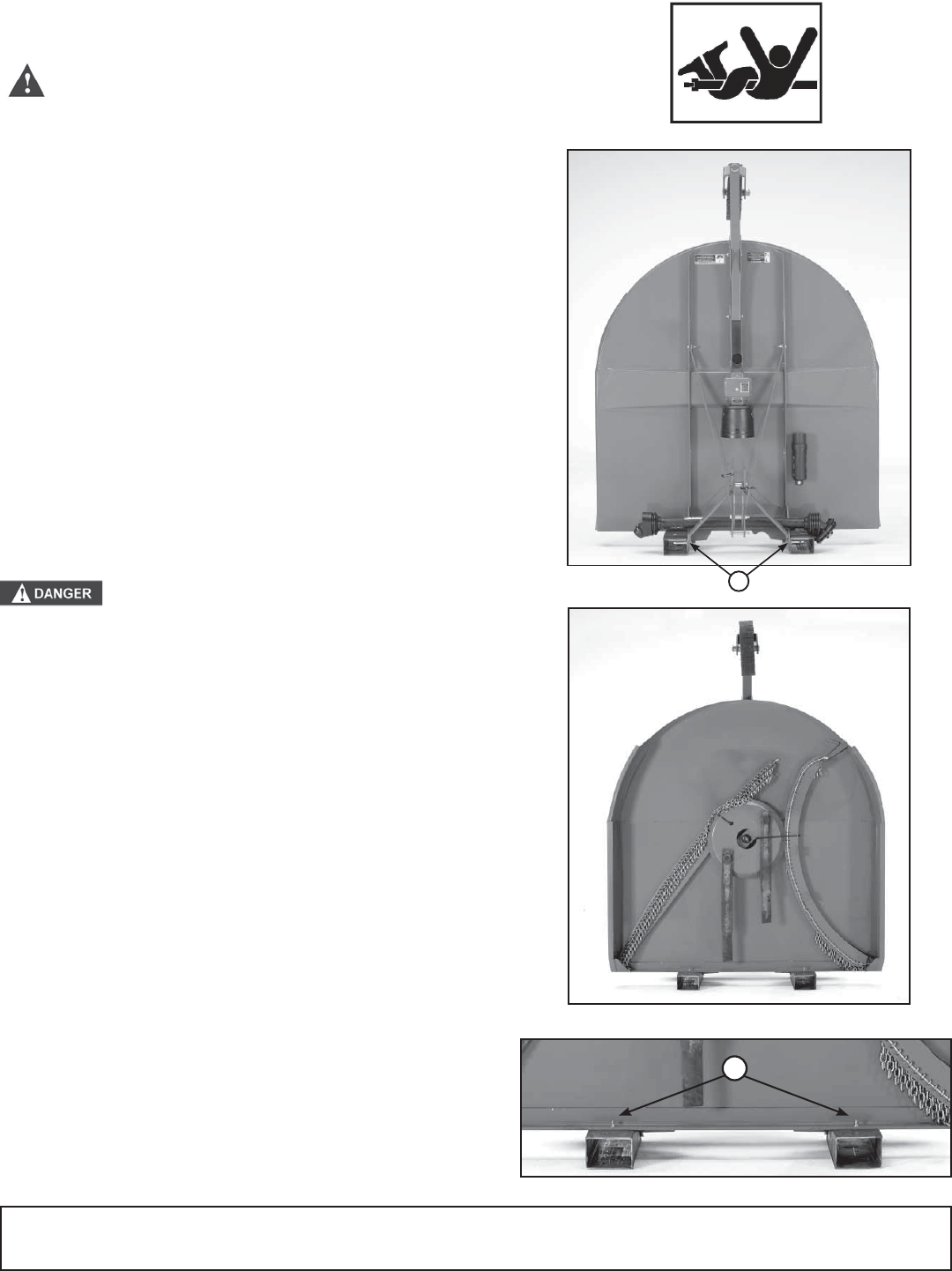

To help prevent bodily injury from

accidental lowering of the cutter, attach a lifting

strap or chains to cutter rear support frame and a hoist.

1. Remove loose parts attached to the cutter on the

underside of the deck and remove additional

hardware from inside of the OM tube.

2. Wrap lifting strap or chains around cutter rear

support frame and attach to a hoist.

3. Lower machine onto 4 inch wood blocks.

4. Remove all shipping bands, wires and loose parts

from around the cutter.

5. Remove shipping stands from cutter by

removing hitch pins (A) and 3/8” bolts (B).

Discard shipping stands, fl at washers and bolts.

6. Install hitch pins and tighten to specifi ed torque.

a) Normal confi guration should be with the hitch

pins facing towards the outside of the cutter.

b) For model RC2048, RC2060 & RC2072 if the

tractor will not extend out far enough for normal

confi guration, the hitch pins can be inverted.

(See attaching Cutter to Tractor with Three-Point

Hitch on page 14 for more details.)

Assembly 29

B

A