Introduction

The CNT-8X counters can complete a

measurement cycle in many different

ways, each with its own advantage. This

means that your first step is to select a ba

-

sic “measurement scenario” based on the

requirements of the measurement. This

chapter contains some measurement sce

-

narios that you can choose from.

These counters can measure with impres

-

sive speed if you program them correctly.

You will find guidelines for speed im

-

provements in each of the described mea

-

surement scenarios.

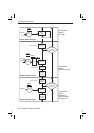

Controller Synchronization

The start of measurements can either be

individually or block synchronized by the

controller. The instrument-to-controller

synchronization deals with how to start a

measurement or sequence of measure-

ments and to read data in the most effi-

cient way. You can also synchronize the

measurement with the measuring object

more accurately by using external control

(arming), but this is not described here.

Measurement Cycle

Synchronization

It is a good practice to check that the

measurement proceeds as planned when

the controller has started a measurement,

or block of measurements.

n

Start

If the input signal fails, or there is no

arming etc., the measurement cycle will

not start.

Timeout

Turn on timeout and set the time longer

than the expected measurement cycle.

Then wait for the timeout period, and

take actions if you got timeout.

If the measurement time is long, you may

have to wait many seconds or even min

-

utes until timeout, just to learn that the

measurement never started.

Measurement started

Before starting a measurement, set up the

status reporting system so that you get a

Service Request on Measure

-

ment-in-progress, bit 4 in the Operation

Status Event Register. Check this with se-

rial poll after a reasonable time when the

measurement ought to be started, lets say

after 100ms (time dependent on input sig-

nal frequency). If the bit is true, continue.

If false, abort the measurement and check

the signals, alert the operator etc.

n

Stop

You must also know when the measure-

ment is completed in order to read out the

results. Should you read results or send

other commands before the measurement

is completed, the measurement will be in

-

terrupted.

You can of course let the controller wait

until you are absolutely certain that the

result is ready, before you fetch it. But it

is better to use *OPC to get an Operation

Complete status message, or *OPC? to

get an ASCii “1” in the output queue,

when the measurement is ready.

*OPC and *OPC? are common com

-

mands described on page 9-124 and

9-125.

7-2 Introduction

How to Measure Fast