19

To avoid water damage or scalding from operation of the

relief valve, install a drain pipe in the outlet of the pressure

relief valve that will direct water discharging from the

valve to a safe place for disposal. Do not install any reduc-

ing couplings or valves in the drain pipe. The drain pipe

must be installed so as to allow complete drainage from

the valve and drain line. The relief valve should be tested

at least once a year by lifting the valve lever.

Explosion hazard. Any heater installed with

restrictive devices in the piping system downstream from

the heater (including check valves, isolation valves, flow

nozzles, or therapeutic pool valving) must have a relief

valve installed as described above. See Page 16.

Risk of fire and explosion. Improper

installation, adjustment, alteration, service, or main-

tenance of the Combination Gas Control Valve can

lead to fire or explosion, causing loss of life, per-

sonal injury, or property damage.

These instructions are for the use of qualified

service technicians only!

Do not attempt this procedure unless you have

been trained and certified in the care and repair of

gas-fired appliances!

Do not attempt this procedure if the following

instructions are confusing!

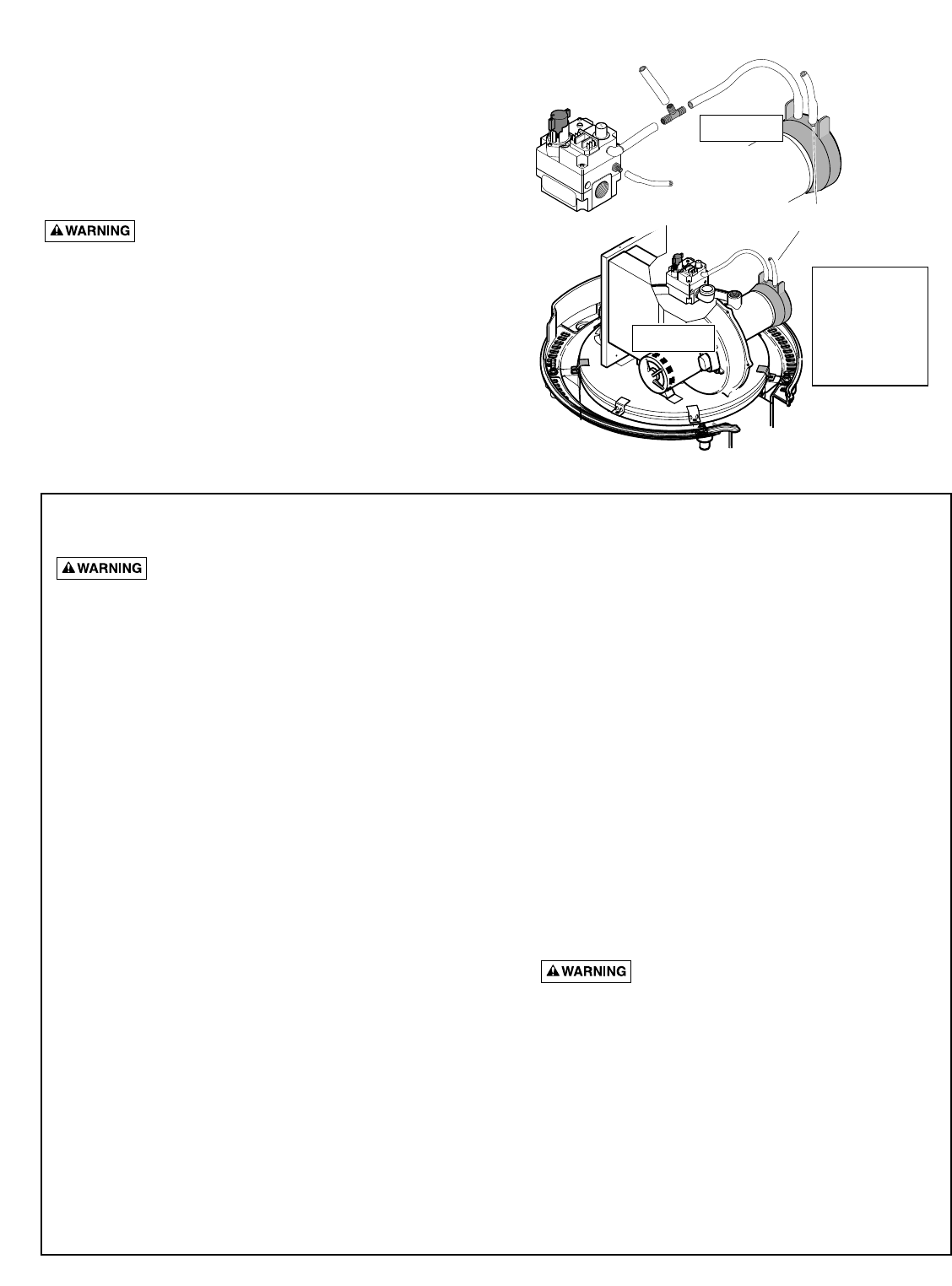

This appliance is equipped with an unconventional gas

control valve that is factory set with a manifold pressure

of –.2” wc. Installation or service must be performed by

a qualified installer, service agency, or the gas supplier.

If this control valve is replaced, it must be replaced with

an identical control.

The combination gas valve incorporates dual shut-off

valves and a negative-pressure regulator. For proper

operation, the regulated pressure at the outlet manifold

of the valve must be 0.2” wc below the reference pres-

sure at the blower mixer inlet, and the gas valve ‘VENT’

tap must be connected to the endcap air orifice as

shown in Figure 21 (above).

Do not attempt to adjust the gas input by adjusting the

regulator setting. The correct gas regulator setting is

required to maintain proper combustion and must not be

altered.

To check that the gas pressure setting is correct,

use the following procedure:

1. Turn off the heater and remove the top covers for

access to the Combination Gas Control Valve.

2. Use a 3/16” hex key to remove the plug from the

‘PRESSURE TAP’ port on the outlet side of the

Combination Gas Control Valve.

3. Install a 1/8” NPT barbed fitting into the ‘PRESSURE

TAP’ port. Use a flexible tube to connect it to the low

side of a differential pressure gauge or a slope

gauge.

NOTICE: If you are using a slope gauge or a differ-

ential pressure gauge of less than 3” capacity, close

the shutoff valve of the gauge to avoid pulling the liq-

uid out of the gauge when the blower starts.

4. Disconnect the tube from the Gas Valve ‘VENT’ port.

Connect it to a tube with a tee running to the high

side of a differential pressure gauge and to the blow-

er’s air orifice grille (See Figure 21, above).

5. Turn on the heater and verify the gas supply pres-

sure (Page 20).

6. After the burner ignites, open the shutoff valve of the

gauge. The pressure gauge should then read 0.2” wc

±0.1” wc (0.0” to 0.1” wc = rich mixture; 0.3” to 0.5”

wc = lean mixture). (Since the pressure tap is con-

nected to the low side of the gauge, the pressure is

actually negative.)

Risk of fire or explosion if

Combination Gas Control Valve is incorrectly

adjusted. If it is necessary to adjust the gas

valve, this must be done only by a qualified

service agency.

7. Turn off the heater.

8. Replace the plastic hose between the ‘VENT’ port

and the inlet of blower mixer. Remove the barbed fit-

ting and replace the plug in the ‘PRESSURE TAP’

port of the gas valve, using a thread sealant

approved for use with natural gas and LPG.

9. Replace the heater covers and cycle the heater to

check for proper operation.

Instructions For Checking the Gas Pressure

Through the Combination Gas Control Valve

PRESS

TAP

VENT

PILOT

OFF

OFF

ON

ON

CAUTION

2788 0397

P

RE

S

S

T

A

B

VE

N

T

P

IL

OT

O

F

F

OFF

O

N

ON

Connection for

Service

Connection for

Test

To Air Flow

Switch

To High Side of Differential

Pressure Gauge

To Low Side of Diff.

Pressure Gauge

NOTICE: The gas

piping and unions

are not shown

for clarity; make

this test with all

gas piping

connected (as for

normal service).

FIGURE 21: Connect Gas Valve to End Cap Air Orifice