20

Replace only one tine at a time. This will help to insure

the correct positioning of the tines as they are mounted

on the tine assembly. When installing the new tine, be

certain that the longer shoulder bolt is in the inner hole

toward the center of the tine assembly. Realign the

bolts and washers as shown in Figure 21 and retighten

firmly.

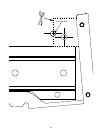

Figure 21

Changing Hydraulic Pump Drive Belt

Allow the machine to cool before performing

maintenance. The muffler and belts will

become hot during normal use.

Figure 22

The hydraulic pump drive belt is located under the

tractor and is driven by the PTO of the tractor. To

remove the belt for inspection or replacement, proceed

as follows:

• Crouch or lie next to the tractor on the right side and

locate the hydraulic pump assembly underneath

the center of the tractor frame. Refer to Figure 22.

• The idler pulley on the right side is attached to the

idler arm and is spring loaded to provide constant

tension to the pulley which keeps the belt tight.

• There is a 3/8” square hole on the outside edge of

the idler arm which is used to relieve belt tension.

Insert the head of a 3/8” ratchet into the square

hole.

• With the ratchet set to tighten, pull on the ratchet

and notice that belt tension is being loosened.

• While holding the ratchet to keep the belt loose,

carefully remove the belt from the large hydraulic

pump pulley and the other stationary idler pulley.

• With the belt removed from the hydraulic pump

assembly, raise the hood of the tractor and locate

the belt where it rests in the pulley of the PTO. The

belt at this point is free of obstruction and can be

removed through the hood opening.

Inspect the belt for any cracks or fraying. Replace if

necessary. Before installing a new belt, check pulley

shafts and bearings for excessive end play and wear.

Make certain that they turn smoothly and freely.

Check pulley grooves for debris build-up or wear. If the

pulleys require cleaning, moisten a cloth with a non-

flammable degreasing agent to clean out the grooves.

Refer to the Mounting the Tiller section earlier in this

manual for instructions on installing the hydraulic pump

drive belt.

Hydraulic Hoses

WARNING: Hydraulic hoses, fittings, and

fluid become hot during normal usage. Allow

the machine and its related hardware to cool

down before performing maintenance.

The hydraulic hoses need to be checked regularly for

cracks or leaks. Hydraulic fittings also need to be

checked for leaks or damage. Replace any hose that

shows signs of cracking or leaking to avoid a

dangerous situation.

Hydraulic fittings that are leaking should be checked to

verify that they are tight. If further leaking persists after

tightening, the fitting or the hose may need to be

replaced.

If fluid is lost during repairs, be sure to check the fluid

level and add as necessary.