SERVICE AND ADJUSTMENTS

REPLACE THE CHIPPER CUTTING BLADE

Over time, the chipper cutting blade edge (A in Figure 33

on Page 31) will dul!. Sharpen or replace the blade

when the chipper no longer cuts efficiently,

_3

E3

Discard a cracked or severely nicked blade because

the blade could break apart and cause personal

injury.

We recommended thatyou takethebladetoa

professional sharpening service for expert

sharpening,, All grinding must be flat and uniform

along the beveled edge of the blade to maintain the

original 45 o cutting angle. Sharpen a blade that is

dull or that has only minor nicks. The blade is made

from tempered steel and is extremely hard - do not

attempt to sharpen with a hand file

iMPORTANT: Do not reuse the blade mounting screws

and locknuts. New screws and tocknuts are supplied

with a new blade Use only factory-supplied

hardware. Do not use substitutes or failure of the

equipment or personal injury could result. See the

Parts List at the back of this Manual to order individual

replacement screws and Iocknuts if re-installing the old

blade.

To Remove and Replace the Blade

1, Stop the engine and make sure that all moving

parts have come to a complete stop. Disconnect the

spark wire and secure it away from the spark plug.

2. Remove the collection bag or the blower deflector,

3o The blade removal procedure requires removal of the

engine. To avoid a potential safety hazard from spilled

gasoline, the fuel tank must be emptied of alt gasoline

before the engine is removed, Follow Steps "a" through

"d" to empty the fuel tank,

a. Place a clean pan below the fuel tank to catch the

gasoline as it drains Remove gas cap from fuel tank,

DANSER

Gasoline and its vapors are highly flammable and

explosive.

To avoid serious personal injury, be sure area is

well ventilated and keep gasoline away from open

flame or sparks, Observeno smoking rules at atl

times_ Use an approvedfuel conlainer.

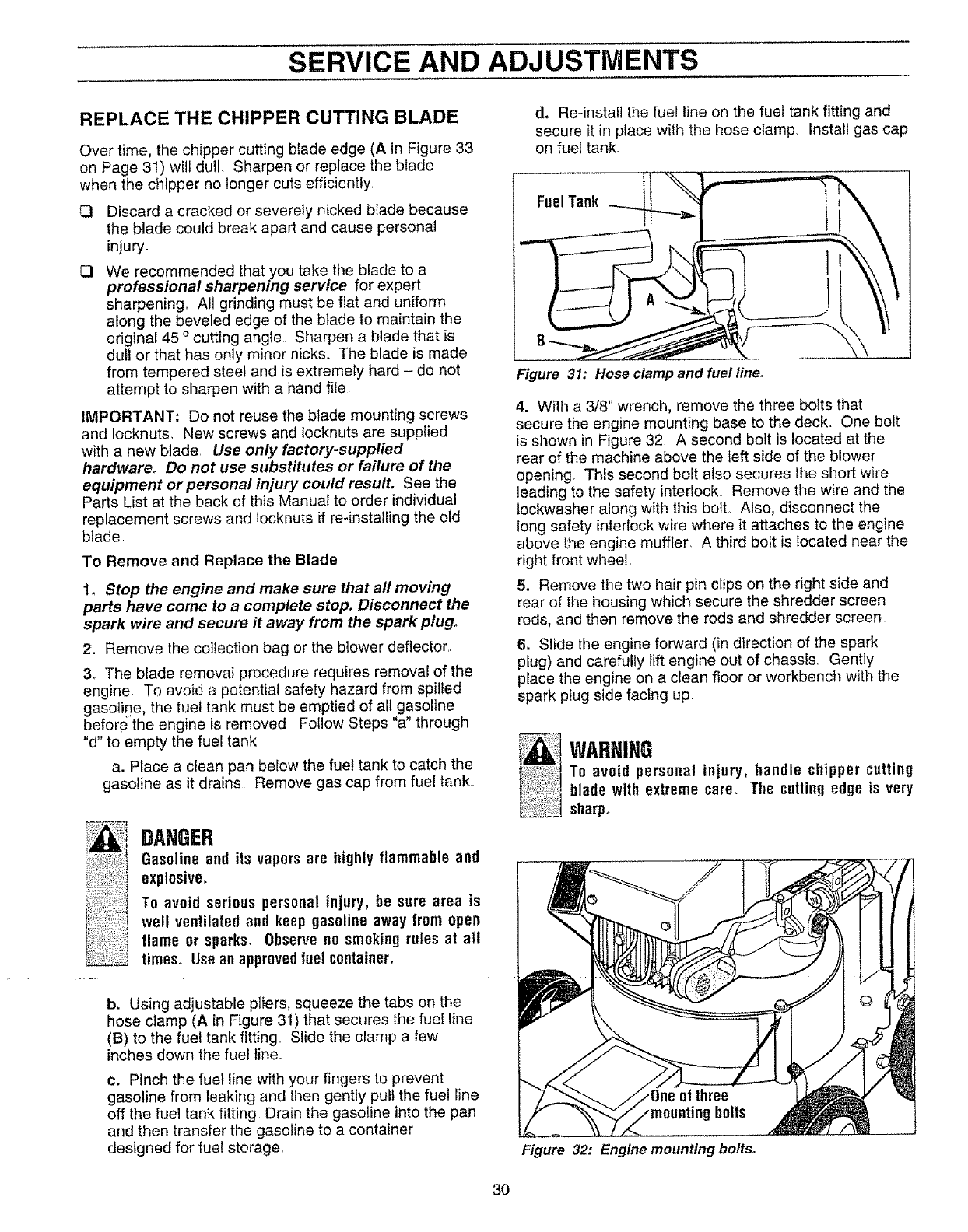

b. Using adjustable pliers, squeeze the tabs on the

hose clamp (A in Figure 31) that secures the fuel line

(B) to the fuel tank fitting. Slide the clamp a few

inches down the fuel Iine.

c. Pinch the fuel line with your fingers to prevent

gasoline from leaking and then gently pull the fuel line

off the fuel tank fitting Drain the gasoline into the pan

and then transfer the gasoline to a container

designed for fuel storage,

d. Re-install the fuel line on the fuel tank fitting and

secure it in place with the hose clamp. Install gas cap

on fuel tank.

FuelTank

Figure 31: Hose clamp and fuel line.

4. With a 3/8" wrench, remove the three bolts that

secure the engine mounting base to the deck. One bolt

is shown in Figure 32. A second bolt is located at the

rear of the machine above the left side of the blower

opening. This second bolt also secures the short wire

leading to the safety interlock,. Remove the wire and the

Iockwasher along with this bolt. Also, disconnect the

long safety interlock wire where it attaches to the engine

above the engine muffler, A third bolt is located near the

right front wheel

5. Remove the two hair pin clips on the right side and

rear of the housing which secure the shredder screen

rods, and then remove the rods and shredder screen,

6, Slide the engine forward (in direction of the spark

plug) and carefully lift engine out of chassis., Gently

place the engine on a clean floor or workbench with the

spark plug side facing up.

WARNIH8

To avoid personal injury, handle chipper cutting

blade with extreme care,, The cutting edge is very

sharp°

Figure 32: Engine mounting bolts.

3O