CUSTOMER RESPONSIBILITIES

To Change the Oil

1, Change the oil while engine is still warm from recent

operation. Stop engine and make sure that all

moving parts have come to a complete stop.

Disconnect spark plug wire and secure it away from

spark plug.

2. The oil drain plug (B in Figure 27 on Page 27) is

located at the bottom of the dipstick tube,.

3. Prop up the wheels on the opposite side of the

machine so that the oil drain plug is at the lowest point

on the engine,

4o To prevent oil from spilling on the machine, make a

V-shaped drain trough out of aluminum foil or stiff

cardboard and place the trough beneath the drain plug,

5. Remove the dipstick (A, Figure 27) to vent the

crankcase and speed up draining time

6. Remove the oil drain plug (B, Figure 27). After the oil

has drained, install the oil drain plug and tighten

securely

7. Refill the engine crankcase with recommended oil

described below. After adding oil, securely replace the

dipstick (A) and clean up any spilled oil

cotder,._ 32°F----------_ - warmer

5W30 SAE 30

SLOT

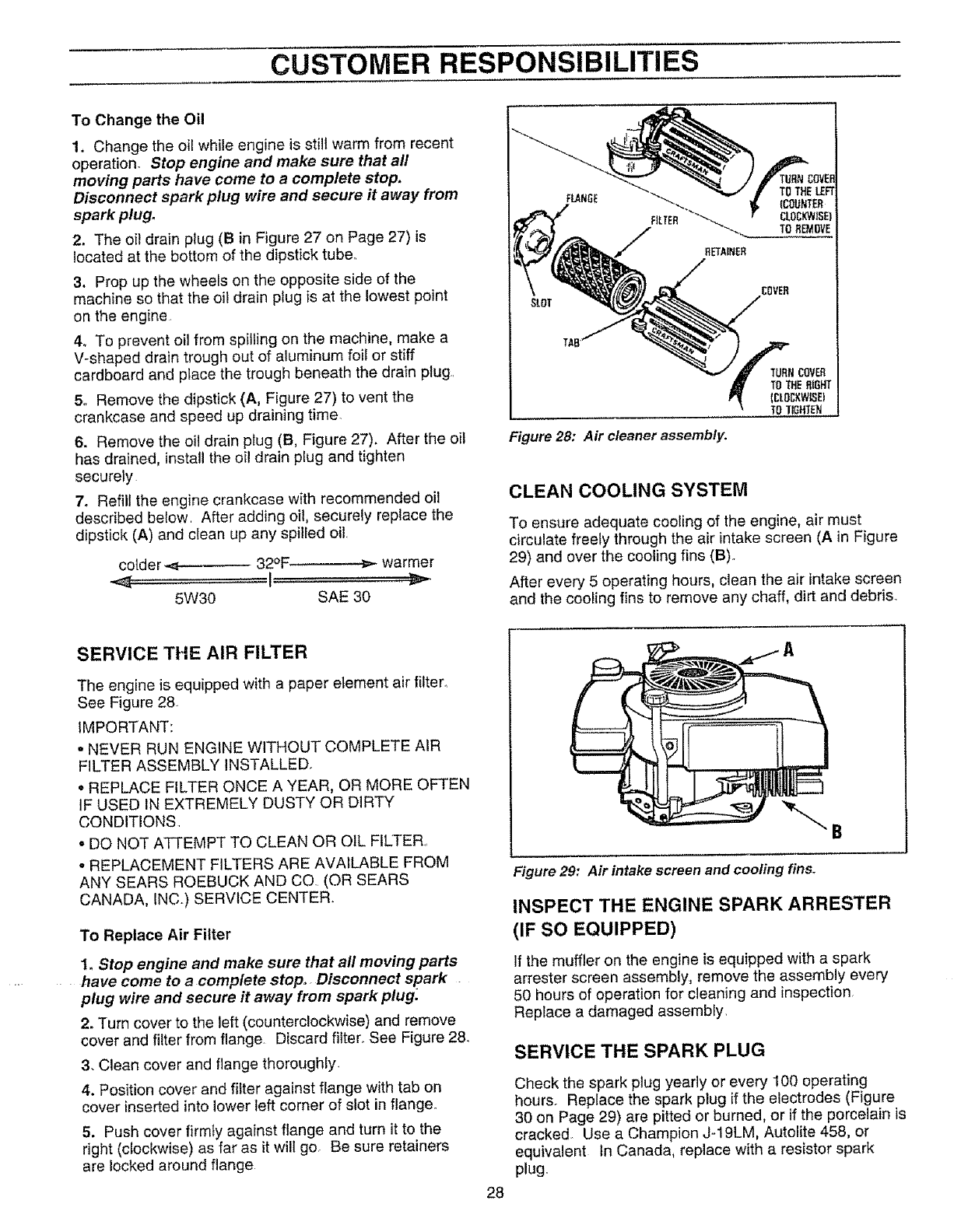

Figure 28: Air cleaner assembly.

CLEAN COOLING SYSTEM

To ensure adequate cooling of the engine, air must

circulate freely through the air intake screen (A in Figure

29) and over the cooling fins (B)..

After every 5 operating hours, clean the air intake screen

and the cooling fins to remove any chaff, dirt and debris.

SERVICE THE AIR FILTER

The engine is equipped with a paper element air filter_

See Figure 28

IMPORTANT:

. NEVER RUN ENGINE WITHOUT COMPLETE AIR

FILTER ASSEMBLY INSTALLED.

* REPLACE FILTER ONCE A YEAR, OR MORE OFTEN

IF USED IN EXTREMELY DUSTY OR DIRTY

CONDITIONS.

- DO NOT ATTEMPT TO CLEAN OR OIL FILTER..

o REPLACEMENT FILTERS ARE AVAILABLE FROM

ANY SEARS ROEBUCK AND CO (OR SEARS

CANADA, INC.) SERVICE CENTER.

To Replace Air Filter

1, Stop engine and make sure that all moving parts

have come to a complete stop. Disconnect spark .

plug wire and secure it away from spark plug;

2. Turn cover to the left (counterclockwise) and remove

cover and filter from flange Discard filter. See Figure 28.

3. Clean cover and flange thoroughly.

4. Position cover and filter against flange with tab on

cover inserted into lower left corner of slot in flange°

5. Push cover firmly against flange and turn it to the

right (clockwise) as far as it will go. Be sure retainers

are locked around flange

28

Figure 29: Air intake screen and cooling fins.

INSPECT THE ENGINE SPARK ARRESTER

(IF SO EQUIPPED)

If the muffler on the engine is equipped with a spark

arrester screen assembly, remove the assembly every

50 hours of operation for cleaning and inspection.

Replace a damaged assembly,

SERVICE THE SPARK PLUG

Check the spark plug yearly or every 100 operating

hours. Replace the spark plug if the electrodes (Figure

30 on Page 29) are pitted or burned, or if the porcelain is

cracked. Use a Champion J-19LM, Autolite 458, or

equivalent In Canada, replace with a resistor spark

plug..